AZ80A magnesium alloy engine case isothermal forging forming mould and method

AZ80A, isothermal die forging technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of difficult forming, uneven microstructure and performance, and low performance of magnesium alloys, and reduce cutting work The effect of high quality, good internal structure performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

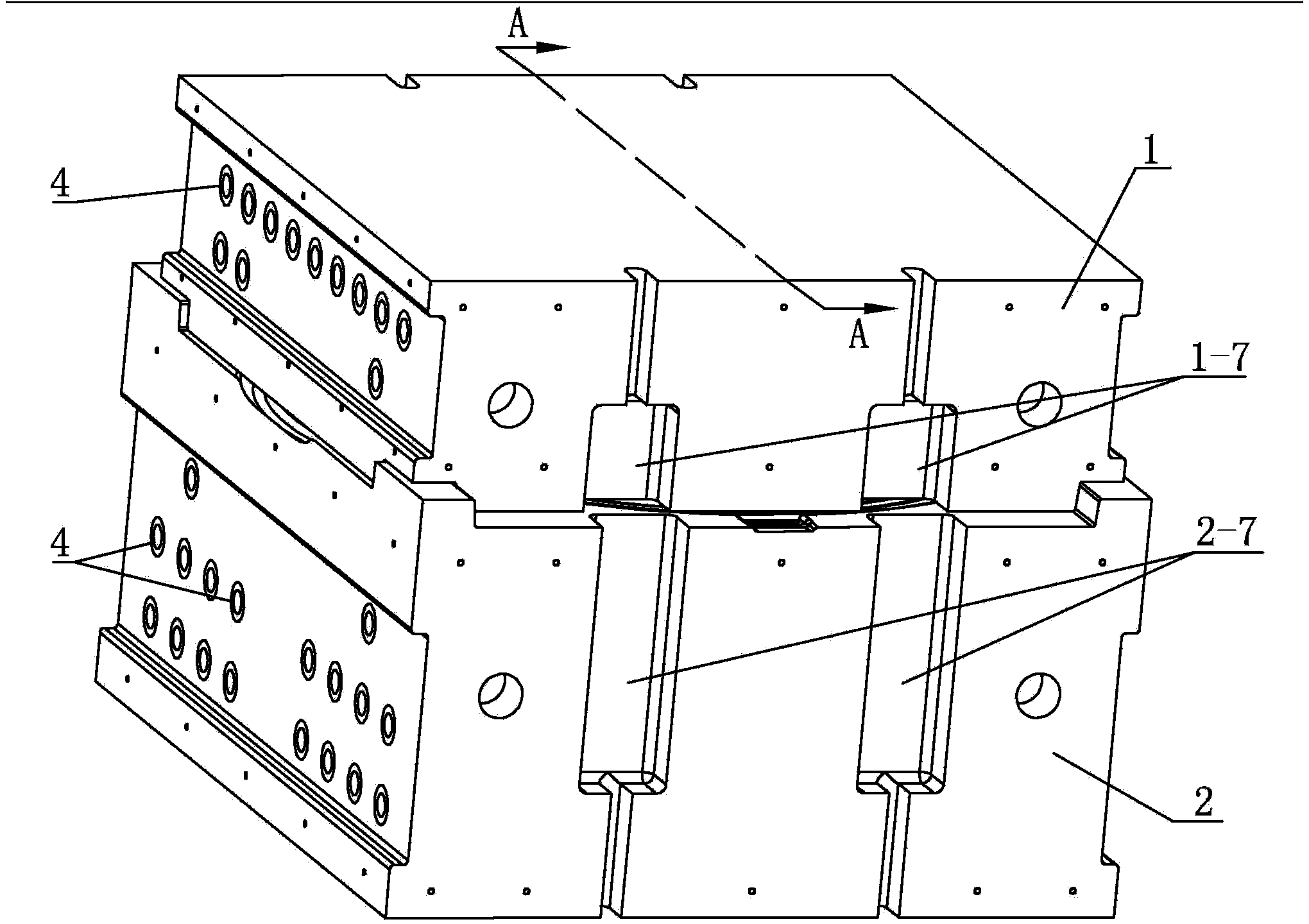

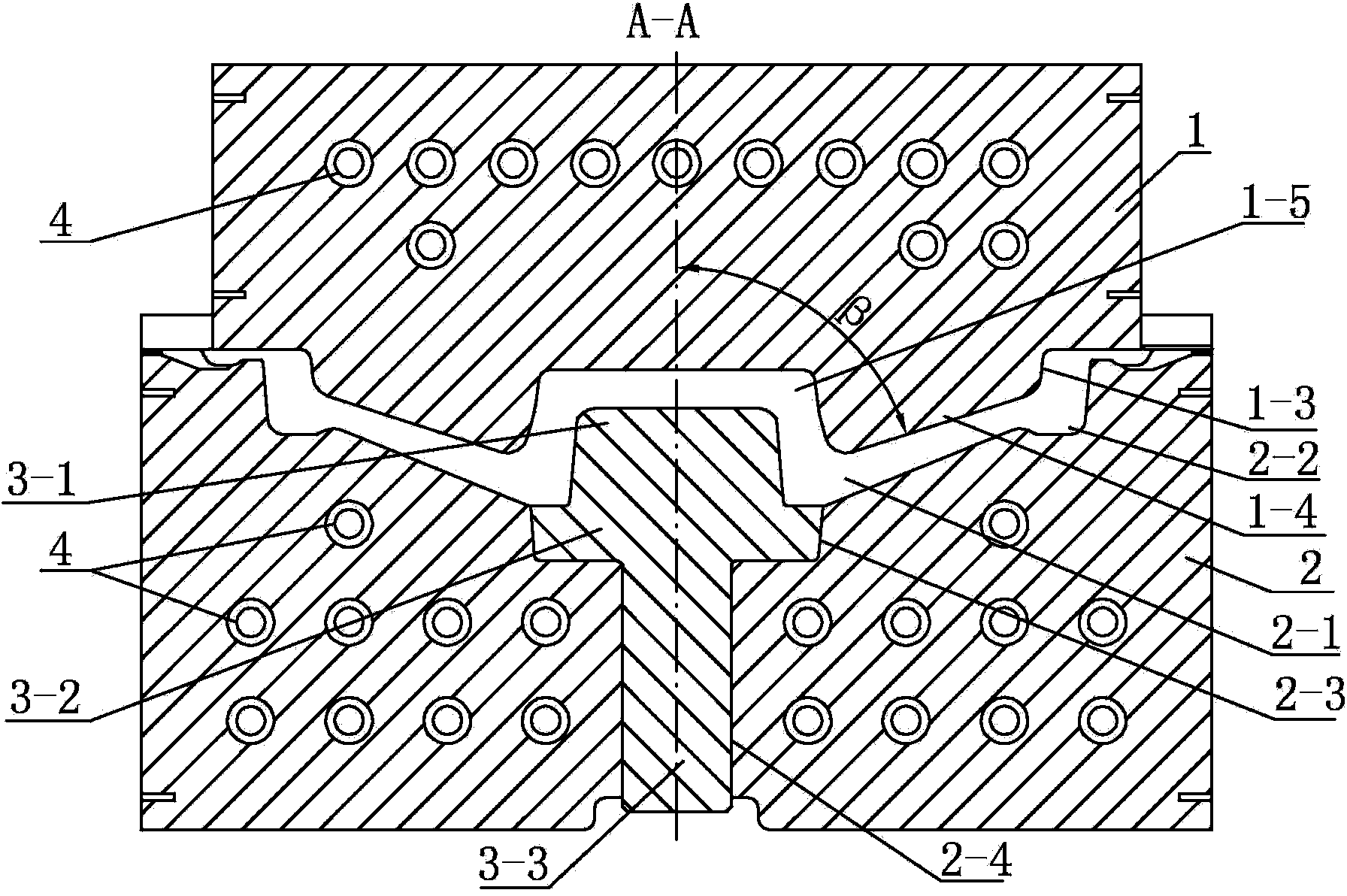

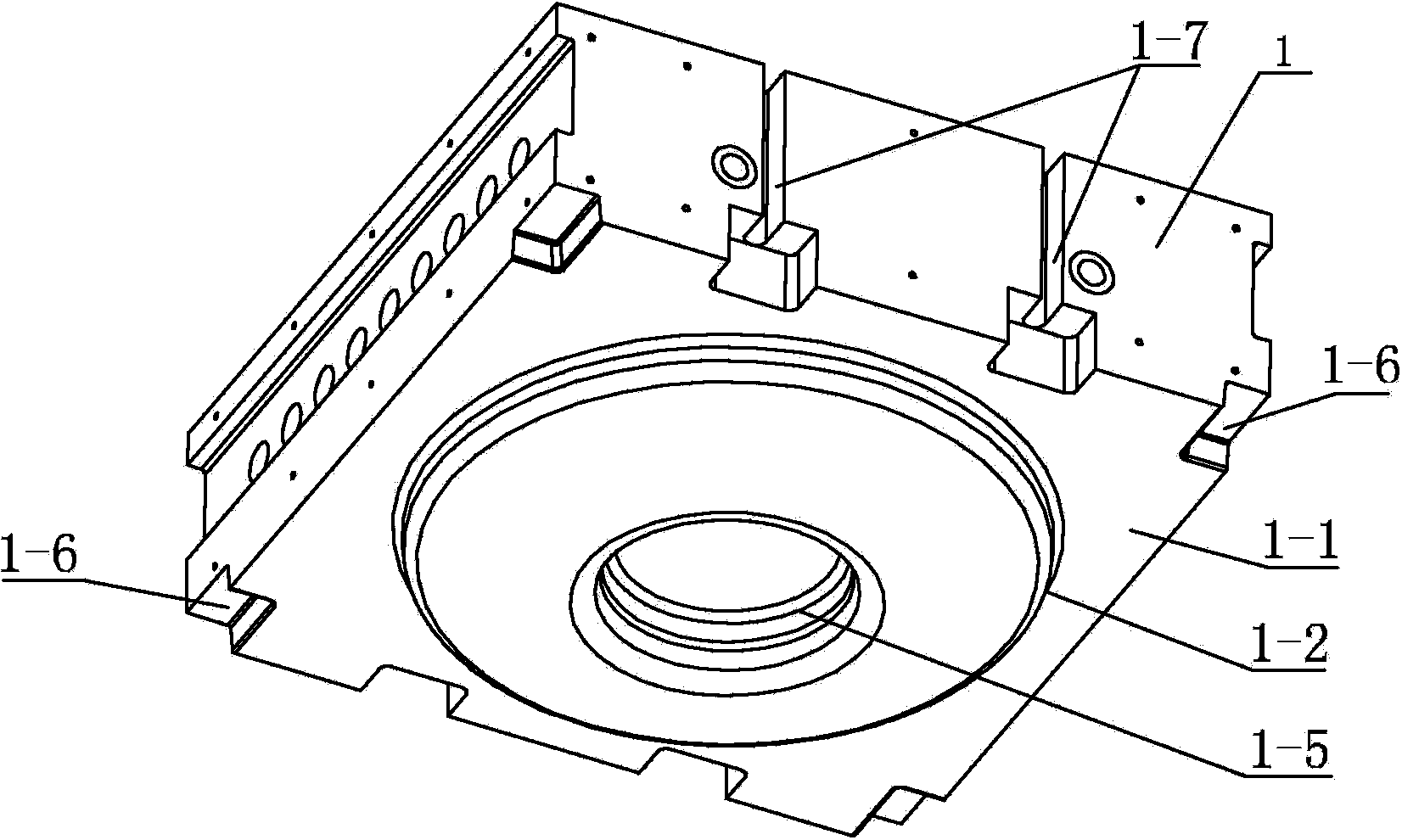

[0021] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment, a kind of AZ80A magnesium alloy casing isothermal die forging forming die of this embodiment includes upper die 1, lower die 2, ejector rod 3 and a plurality of electric heating coils 4, and described upper die 1 is made of An integral body 1-1 and a rib 1-2 are formed, the body 1-1 is a square body, and the middle part of the lower end surface of the body 1-1 is provided with a rib 1-2, and the rib 1-2 is made of the same The shaft is set and made into one first cylinder 1-3 and the first circular platform 1-4, the upper end of the first cylinder 1-3 is connected with the body 1-1, the lower end of the first cylinder 1-3 is connected with the first circular platform 1 The large-diameter end of -4 is connected, and the middle part of the first circular platform 1-4 and the first cylinder 1-3 is processed with a coaxial first tapered groove 1-5, and the cross-sectional diameter of the ...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 2To describe this embodiment, the lower end of the first cylinder 1-3 and the large-diameter end of the first circular platform 1-4 in this embodiment have a circular arc transition. With such a setting, it is convenient to manufacture the magnesium alloy casing, which meets the design requirements and actual needs. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 2 To describe this embodiment, the included angle β between any generatrix of the first circular platform 1-4 and the axis in this embodiment is 72°. Such settings meet the design requirements and actual production needs. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com