Torsionproof steel wire rope cleaning, detecting and maintaining integrated equipment

A steel wire rope cleaning technology, applied in the field of anti-twist steel wire rope cleaning, detection and maintenance integrated equipment, can solve problems affecting construction safety, incomplete cleaning of steel wire ropes, hidden dangers are not easy to find, etc., to achieve online non-damage detection, fine maintenance, and improve safety Detection and maintenance efficiency, good automatic continuous cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

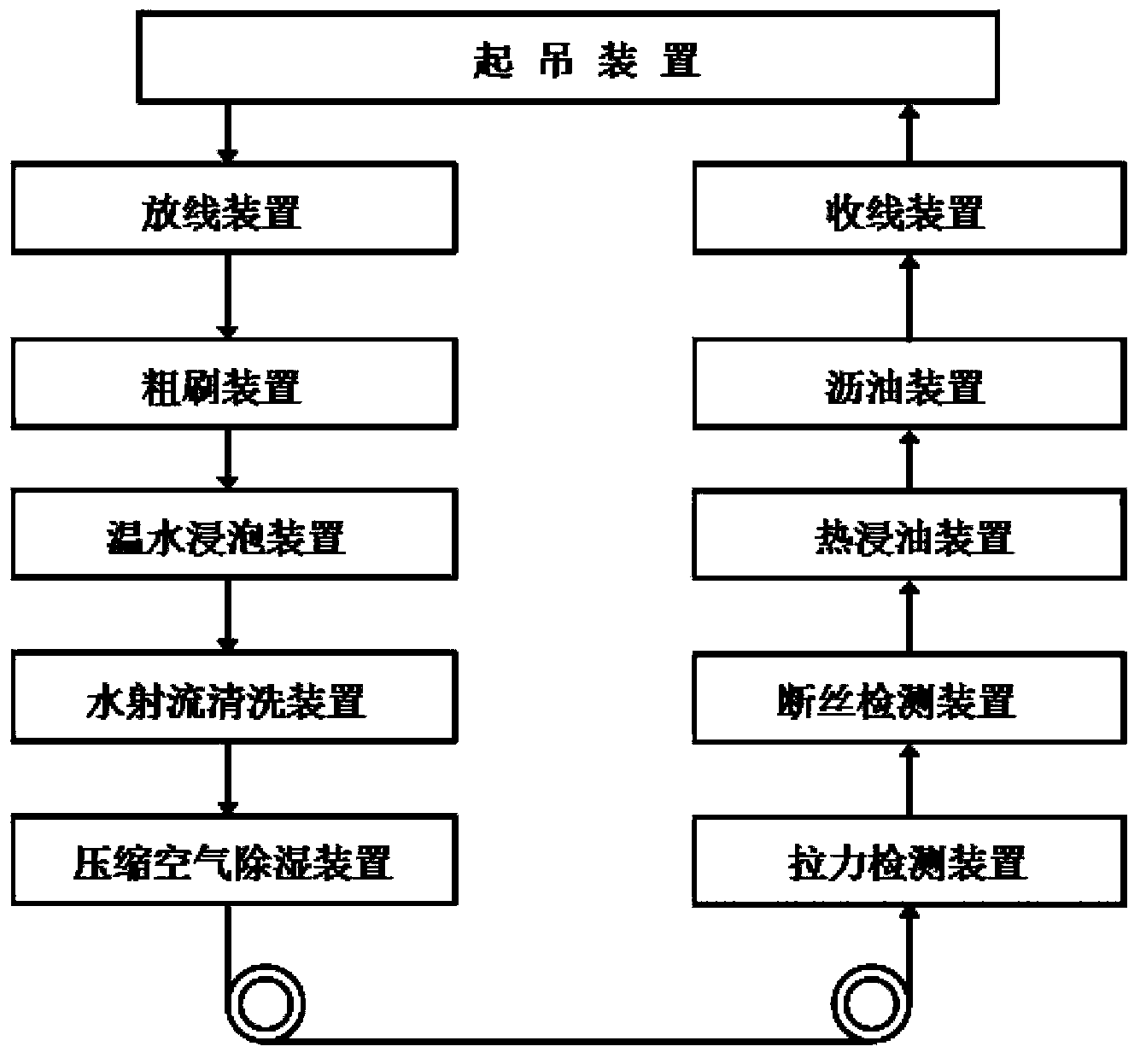

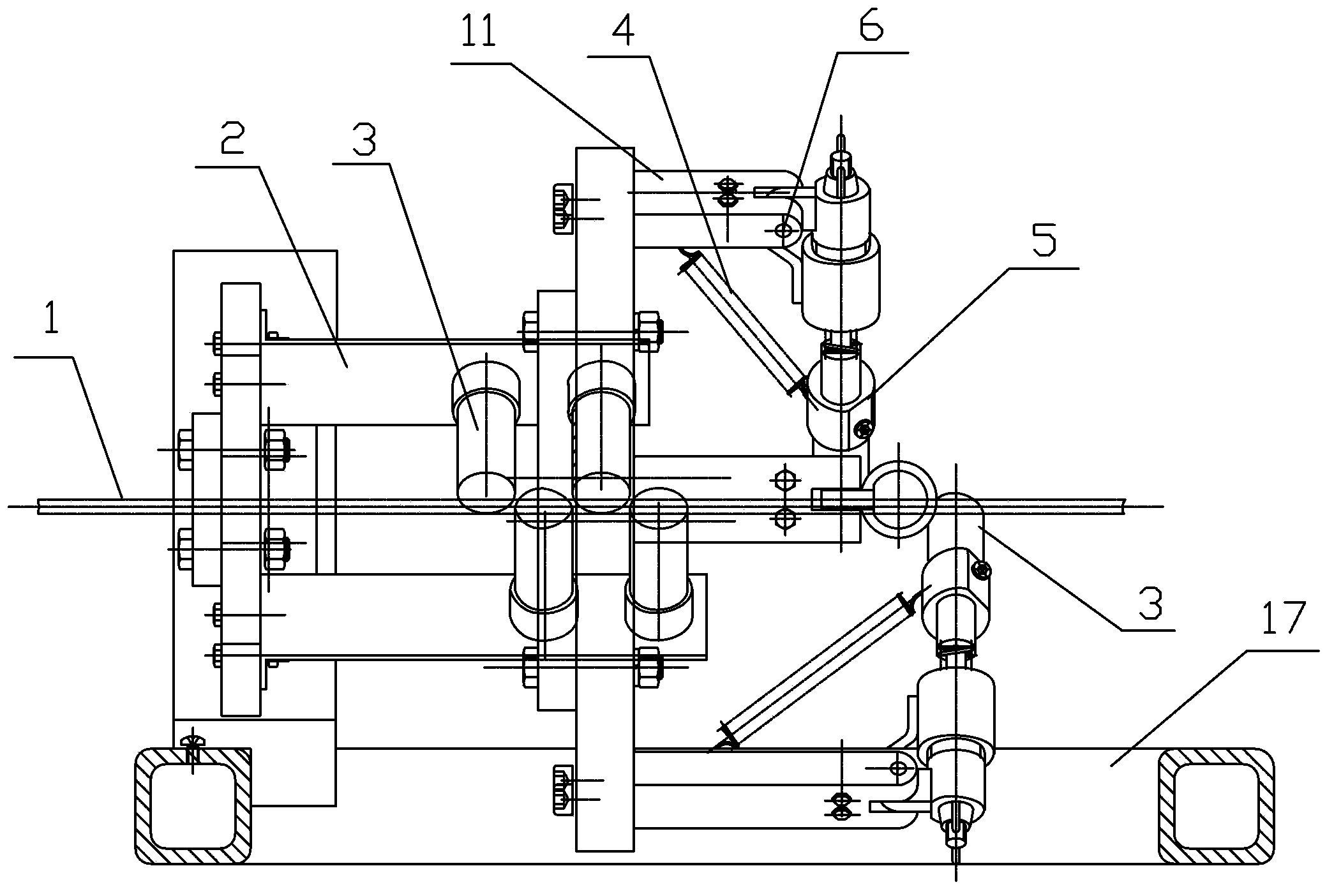

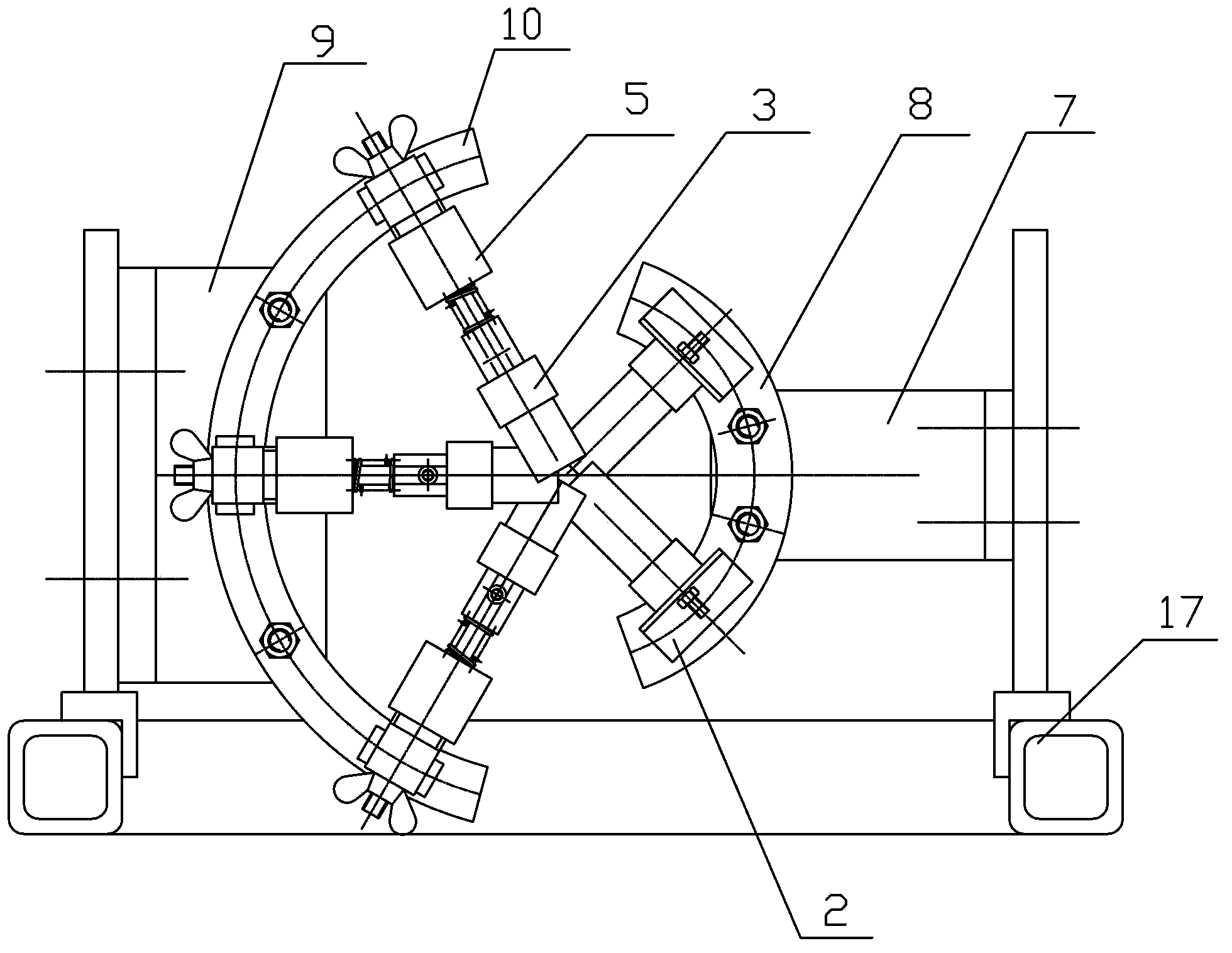

[0058] Refer to the attached Figure 1 to Figure 19 The anti-twist steel wire rope cleaning detection and maintenance integrated equipment of the present invention will be described in detail below.

[0059] The anti-twisting steel wire rope cleaning, detection and maintenance integrated equipment of the present invention has a structure including a lifting device, a wire release device, a water jet cleaning device, a broken wire detection device, a hot oil soaking device and a wire take-up device, and is characterized in that: the release A coarse brushing device and a warm water soaking device are provided between the wire device and the water jet cleaning device, a compressed air dehumidification device and a tension detection device are provided between the water jet cleaning device and the broken wire detection device, and the hot dipping oil An oil draining device is arranged between the device and the wire take-up device, the lifting device, the wire-releasing device, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com