Energy-saving high-efficiency self-cleaning polymerizing device

A polymerization device and self-cleaning technology, applied in damage protection, chemical/physical/physicochemical processes, lighting and heating equipment, etc., can solve problems such as difficult operation, reduction of product purity, and product quality degradation, so as to improve reaction efficiency, Thorough polymerization reaction and quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

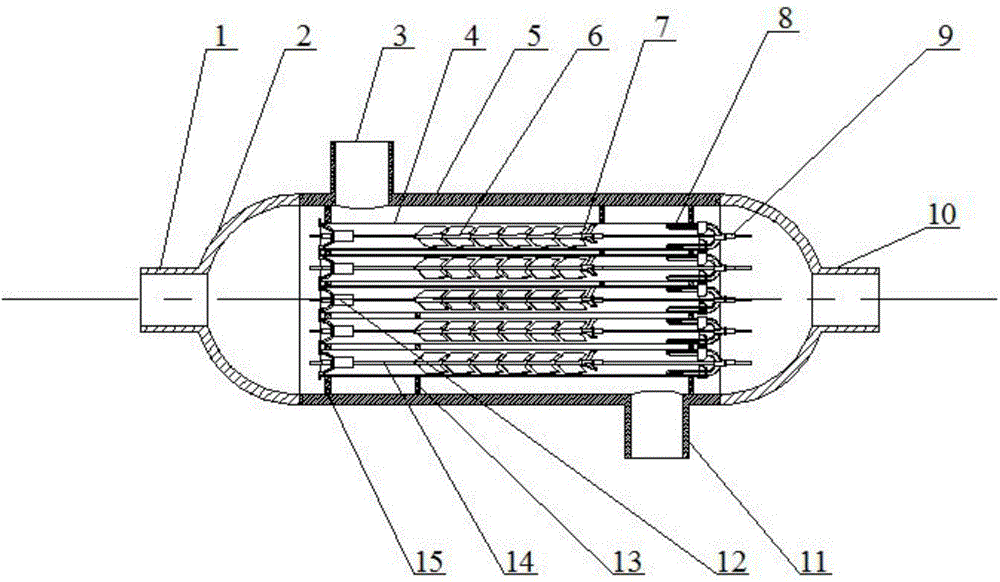

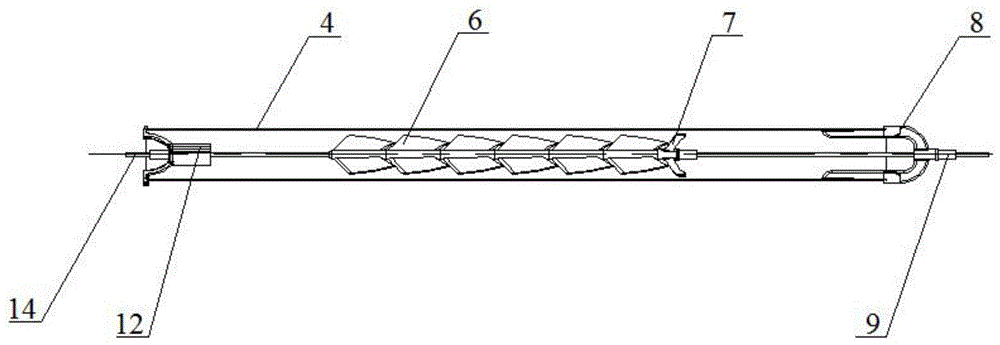

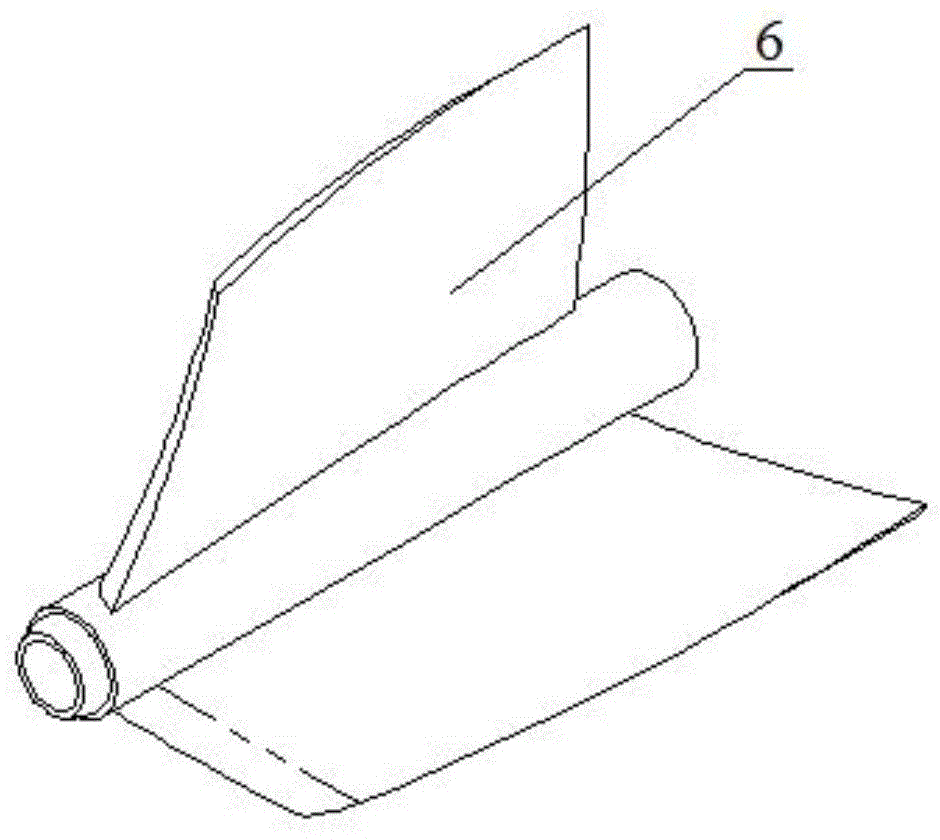

[0026] Such as figure 1 As shown, an implementation method of an energy-saving and high-efficiency self-cleaning polymerization device related to the present invention, the device is composed of a tube-and-tube reactor and a rotor-type self-cleaning enhanced heat transfer device; the tube-and-tube reactor consists of a head 2. It is composed of tube array 4, cylinder body 5, baffle plate 13 and tube plate 15, and adopts conventional design structure and assembly relationship; the self-cleaning enhanced heat transfer device mainly includes rotor 6, intermediate support frame 7, and backwater end pendant 8 , a limiter 9 and a hook hanger 12; the upstream end of the tubes is provided with a hook hanger 12, the backwater end of the tubes is provided with a backwater end hanger 8, and the two ends of the rotating shaft 14 are fixedly supported on the hanger by the limiter 9, The rotating shaft 14 passes through the shaft hole of the rotor 6, the hollow shaft 7-2 shaft hole of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com