Piezosurgery machine working tip

A working tip, bone knife technology, applied in anatomical instruments, medical science, surgery, etc., can solve the problems of difficulty, damage, and small incision in the expansion and grinding of the bone surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

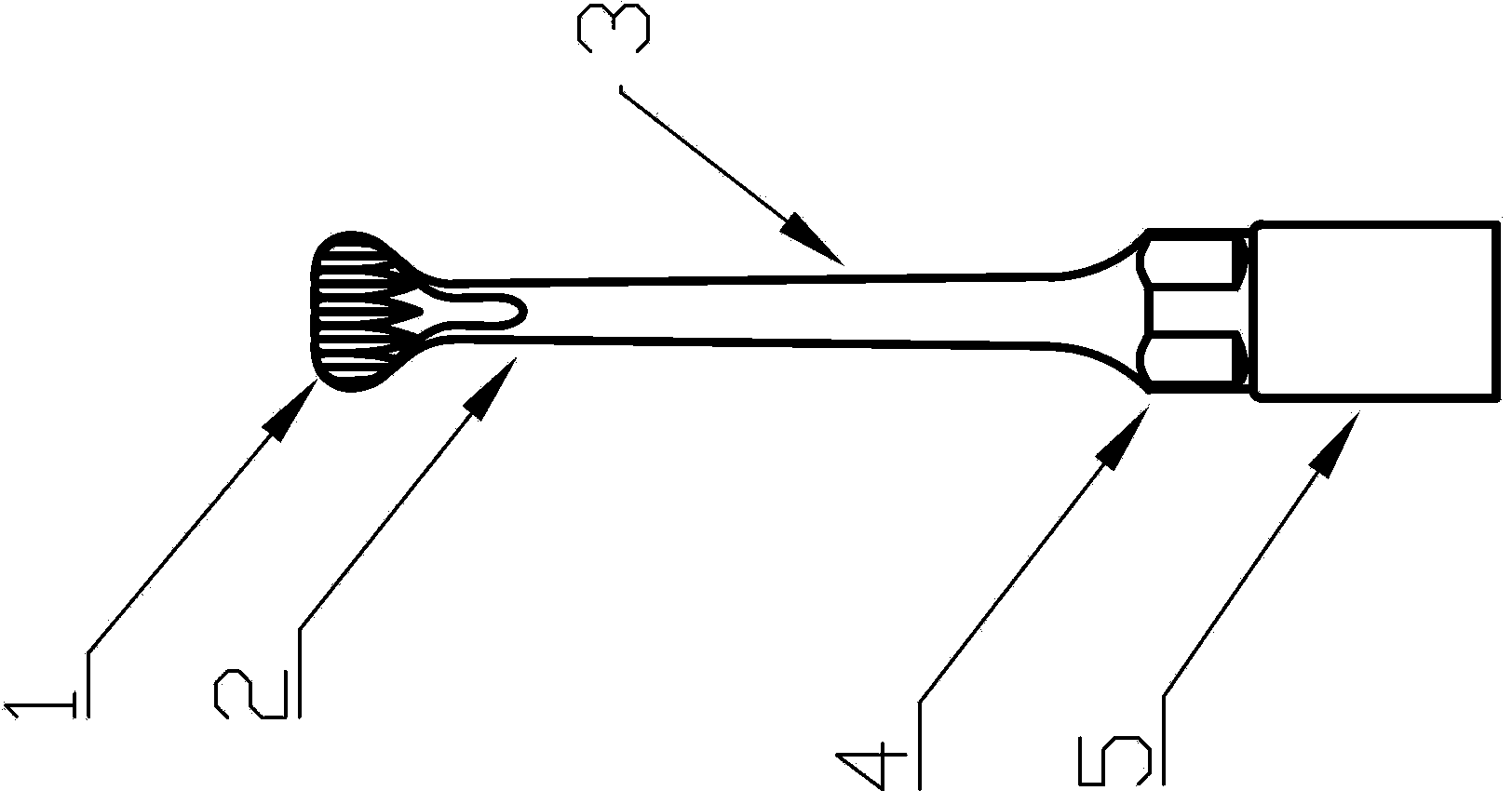

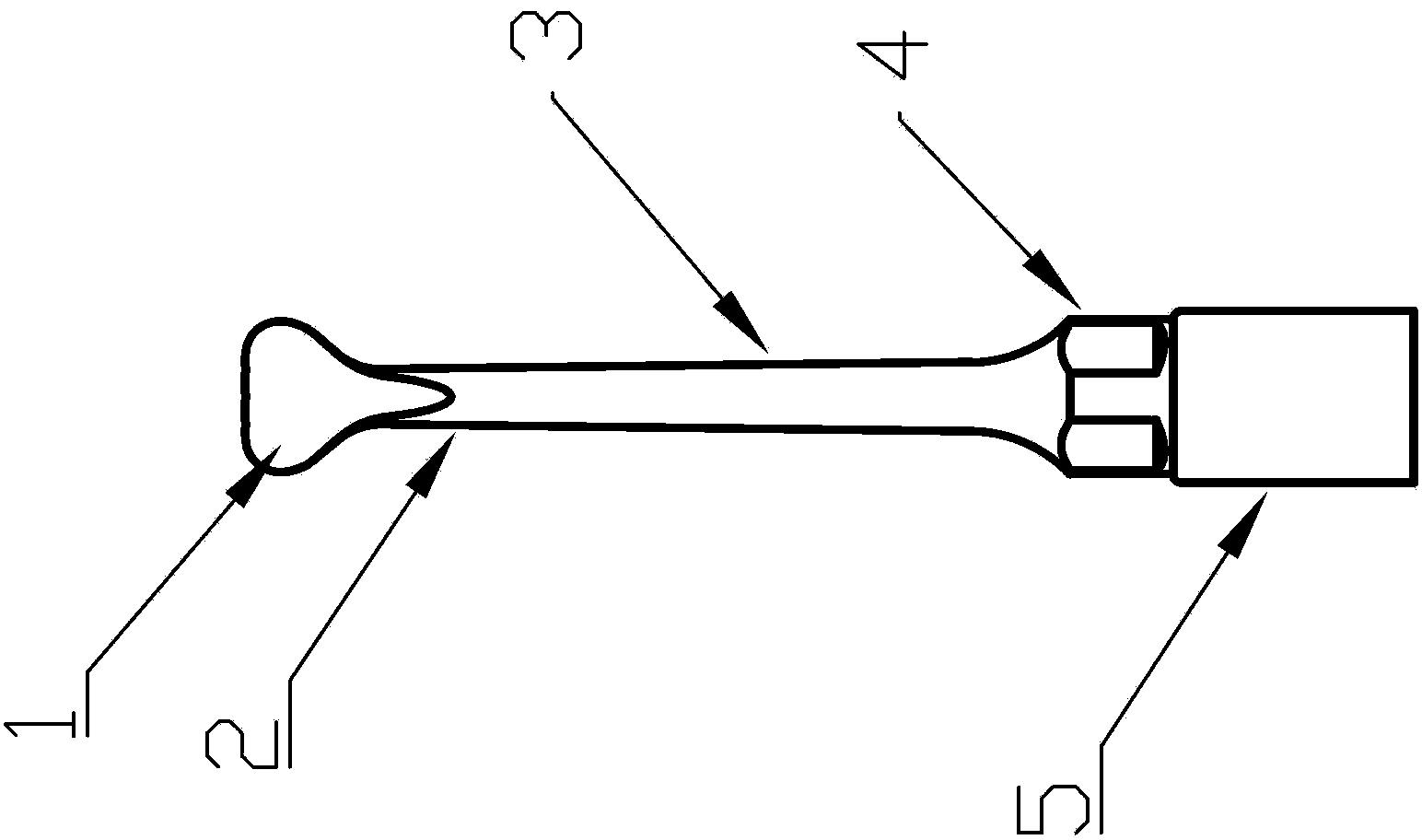

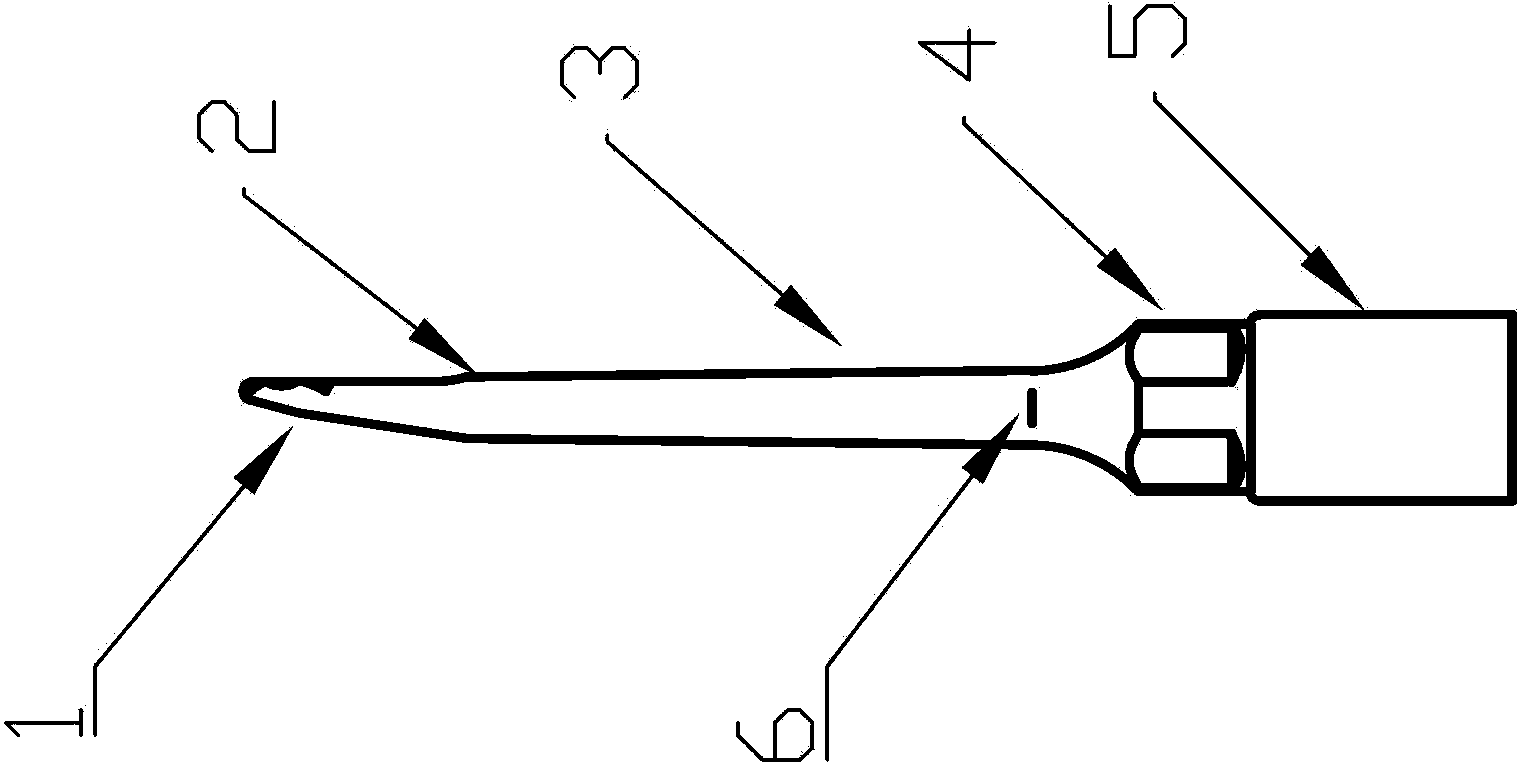

[0021] figure 1 , figure 2 , image 3 The working tip of the ultrasonic bone knife machine shown is composed of a working tip head 1, a working tip head 2, a working tip neck 3, and a working tip connecting part 5, as shown in Figure 4 , Figure 5 The working tip 1 shown is a flat spoon-shaped plane, one of which has a wavy protrusion, and the other side is a smooth surface, and the wavy protruding side can be set on any surface of the working sharp knife 1; the front end of the smooth surface is a slope structure, and the slope The angle is set to 5 to 30 degrees, preferably 15 degrees; the number of wavy protrusions is 2 to 8, preferably 6, and the wavy protrusions are preferably conical tooth-shaped protrusions; the wavy protrusions of the working sharp knife head 1 The height of the wavy protrusion is 0.3mm-0.5mm, and the peak spacing is 0.4mm-1.0mm; the preferred height of the wavy protrusion is 0.4mm, and the peak spacing is preferably 0.8mm; the plane of the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com