Composition comprising water-soluble plukenetia volubilis linneo protein powder and preparation method of composition

The technology of satoshi fruit and its composition is applied in the field of composition containing water-soluble satoshi fruit protein powder and its preparation, which can solve the problems of difficulty in swallowing, low nutritional value, bad taste, etc., and achieve increased content, Nutrient-rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

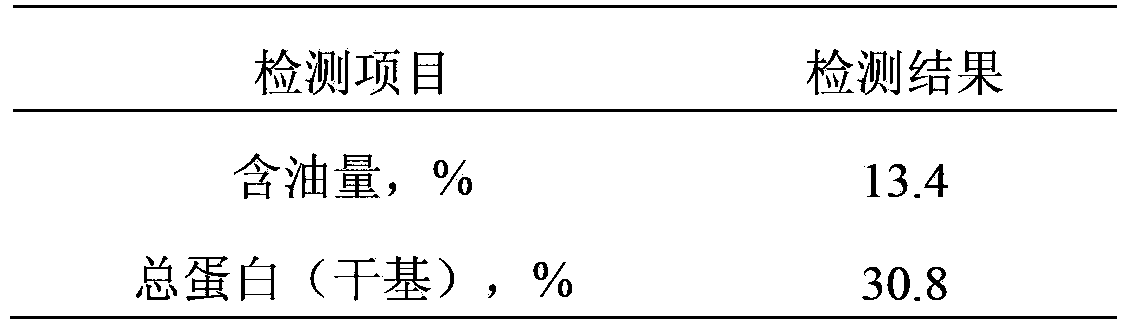

[0037] Embodiment 1: the preparation of water-soluble cane fruit protein powder

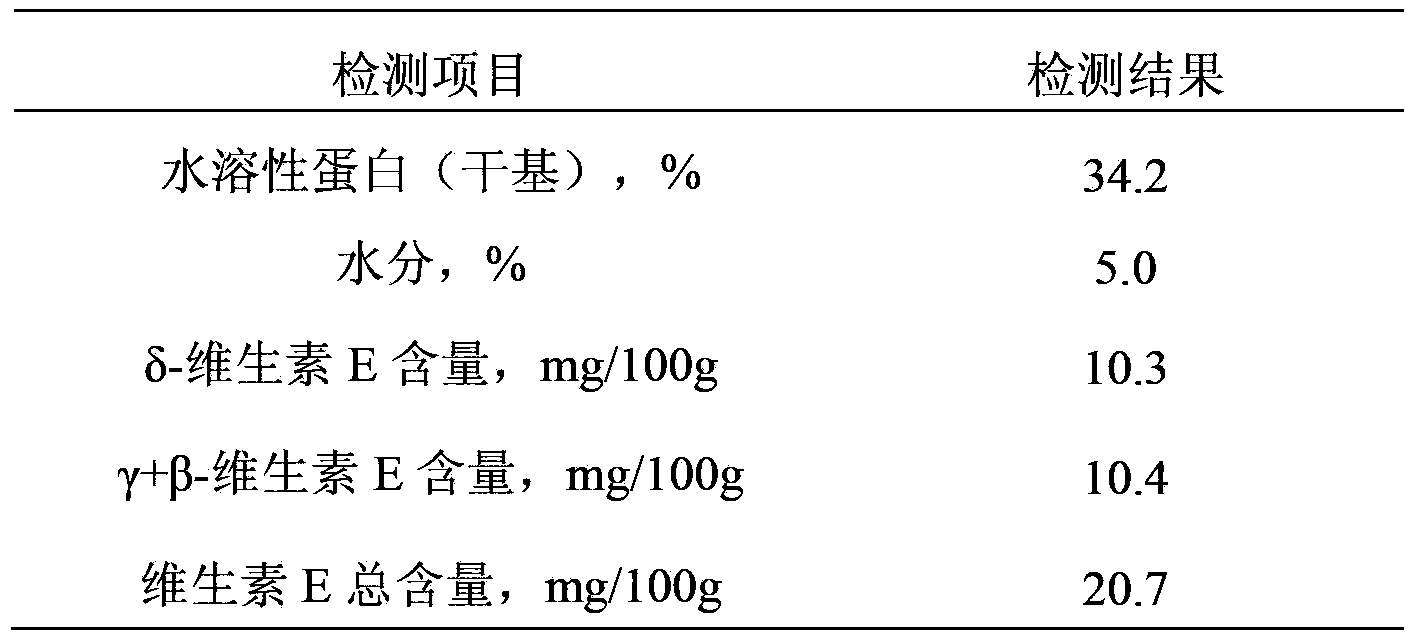

[0038] Take the cane fruit oil cake, pulverize it through a non-heating pulverizer, sieve, weigh 100 grams of powder solids that have passed through an 80-mesh sieve, add 150 ml of water to heat and stir, and boil the feed liquid for 90 minutes to promote the dissolution of soluble components in the feed liquid. Fully dissolve. Then grind the feed liquid with a colloid mill to a particle size of 0.2 microns, and then use a high-pressure homogenizer for high-pressure homogenization; stir and boil the homogenized feed liquid for 90 minutes, cool down to 55 degrees Celsius, filter, and separate the filter residue and filtrate. Then carry out microwave vacuum drying to the filtrate, the drying pressure is maintained at -0.08MPa, after drying, it is pulverized to obtain a milky white loose solid powder, which is sterilized by ultraviolet light for 15 hours, and then packaged to obtain water-soluble c...

Embodiment 2

[0043] Embodiment 2: the preparation of water-soluble cane fruit protein powder

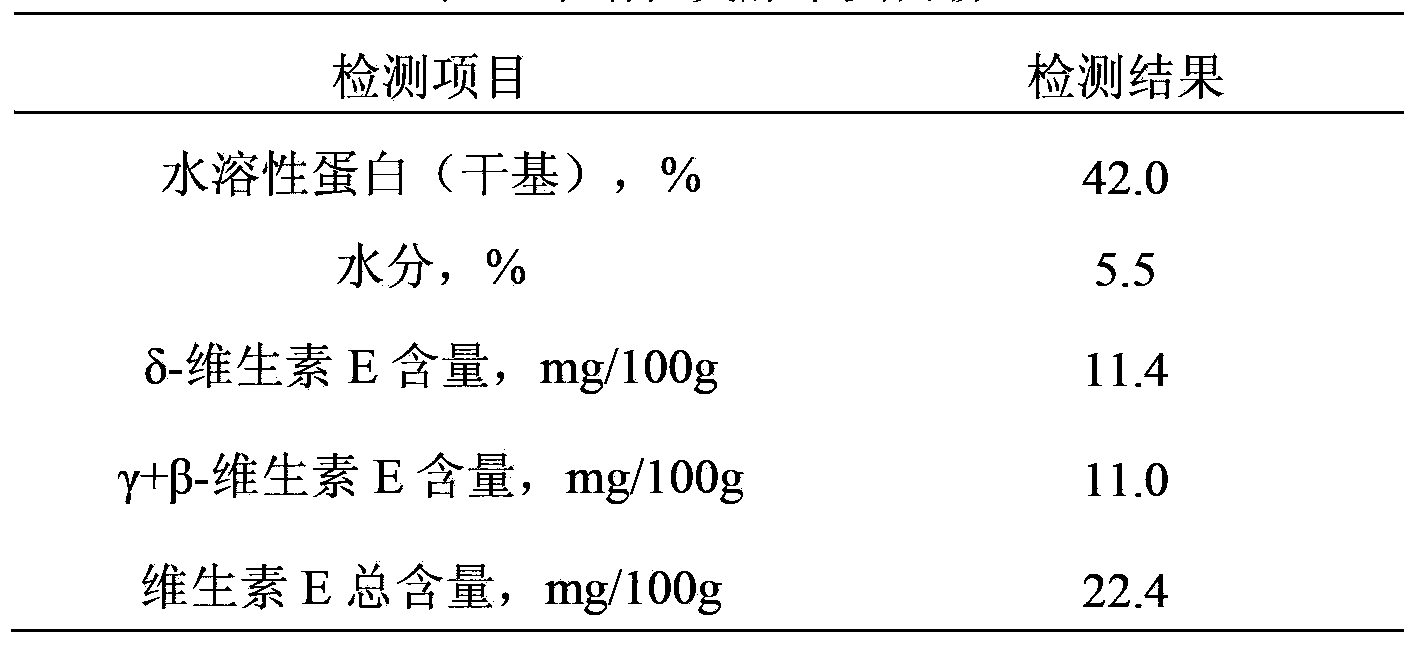

[0044] Take the cane fruit oil cake, pulverize it through a non-heating pulverizer, sieve, weigh 100 grams of powder solids that have passed through a 60-mesh sieve, add 200 ml of water to heat and stir, and boil the feed liquid for 30 minutes to promote the dissolution of soluble components in the feed liquid. Fully dissolve. Then grind the feed liquid with a colloid mill to a particle size of 0.2 microns, and then use a high-pressure homogenizer for high-pressure homogenization; stir and boil the homogenized feed liquid for 60 minutes, cool down to 60 degrees Celsius, and filter to separate the filter residue and filtrate. Then carry out microwave vacuum drying to the filtrate, and the drying pressure is maintained at -0.070MPa. After drying, it is pulverized to obtain a milky white loose solid powder, which is sterilized by ultraviolet light for 12 hours, and then packaged to obtain water-sol...

Embodiment 3

[0047] Embodiment 3: the preparation of water-soluble cane fruit protein powder

[0048] Take the cane fruit oil cake, pulverize it through a non-heating pulverizer, sieve, weigh 100 grams of powder solids that have passed through a 200-mesh sieve, add 100 ml of water to heat and stir, and boil the feed liquid for 200 minutes to promote the dissolution of soluble components in the feed liquid. Fully dissolve. Then grind the feed liquid with a colloid mill to a particle size of 0.2 microns, and then use a high-pressure homogenizer for high-pressure homogenization; stir and boil the homogenized feed liquid for 200 minutes, cool down to 45 degrees Celsius, and filter to separate the filter residue and filtrate. Then carry out microwave vacuum drying on the filtrate, the drying pressure is maintained at -0.098MPa, after drying, it is pulverized to obtain a milky white loose solid powder, which is sterilized by ultraviolet light for 24 hours, and then packaged to obtain water-solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com