Chemically strengthened glass for display devices

A technology for strengthening glass and display devices, which is applied in transportation, packaging, thin material handling, etc., to achieve the effects of less light leakage, high transparency, excellent appearance and practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

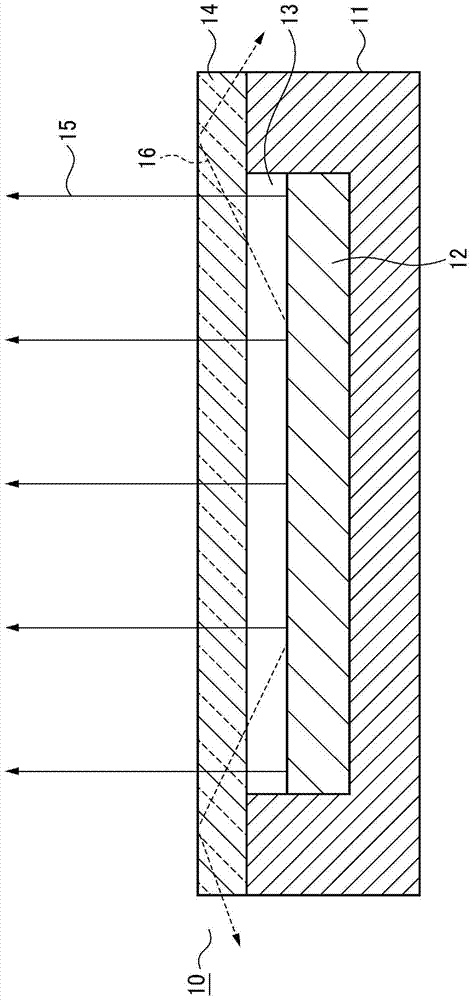

Image

Examples

Embodiment

[0147] The following glass plates are prepared by slowly cooling molten glass to room temperature, followed by cutting, chipping, double-sided mirror grinding, etc.:

[0148] Composition expressed in mol% for SiO 2 : 64.5%, Al 2 o 3 : 6.0%, Na 2 O: 12.0%, K 2 O: 4.0%, MgO: 11.0%, CaO: 0.1%, SrO: 0.1%, ZrO 2 : In 100 parts by mass of matrix glass at 2.5%, Fe is contained in the ratio shown in parts by mass in the corresponding column of Table 1 2 o 3 , NiO, CoO Examples 1, 3-5, 7, 10, 16, 17, 20-22, 28 glass plates (thickness 4mm, 0.7mm, etc., size 50mm×50mm, etc.).

[0149] It should be noted that, in Table 1, the numerical values expressed in parts by mass per 100 parts by mass of the matrix glass are equal to the numerical values expressed in % by mass. For example the Fe of Example 1 2 o 3 It is 0.20% by mass. In addition, SnO 2 , Sb 2 o 3 The contents are all below the detection limit, less than 0.01% by mass.

[0150] Then, a glass plate with a thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com