Graphene/magnetic nanoparticle-modified electrode and its preparation method and use

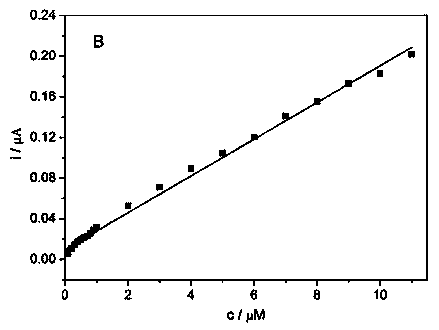

A technology of magnetic nanoparticles and modified electrodes, which is applied in the field of food safety monitoring, can solve the problems of easy contamination of the electrode surface, short service life, and decreased sensitivity, and achieve the effect of accelerating electron transfer rate, improving detection sensitivity, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 graphene

[0028] 100 g of graphene oxide powder was dispersed in 200 mL of double-distilled water, ultrasonicated for 3 hours in a sonicator, and then the unexfoliated blocky graphene was removed at a centrifugal speed of 3000 r, and then 200 μL of hydrazine hydrate and 3 mL of ammonia solution was stirred vigorously to obtain a uniformly dispersed solution; the solution obtained in the above steps was refluxed in an oil bath at 80°C for 12 hours, and the product was centrifuged and vacuum-dried to obtain graphene.

Embodiment 2

[0029] Embodiment 2 Preparation of graphene / magnetic nanoparticles

[0030] 200 mg of graphene, 344.4 mg of FeCl 2 ?4H 2 O, 561.9 mg of FeCl 3 Disperse in 200 mL of double-distilled water, add 1.5 mL, 10 mol / L sodium hydroxide to adjust the pH value of the solution to 11-12, then heat the solution to 80 °C and stir for 1 hour, the product is obtained by distilled water Washed twice with sub-distilled water, and finally dried in a vacuum oven at 60 °C to obtain graphene / magnetic nanoparticles.

Embodiment 3

[0031] Example 3 Preparation of Graphene / Magnetic Nanoparticle Modified Electrode

[0032] Pretreatment of the glassy carbon electrode: the glassy carbon electrode is based on the existing commercially available glassy carbon electrode, and the glassy carbon electrode is polished with alumina powder with a particle size of 0.05 μm, then rinsed with double distilled water, and then washed in acetone, nitric acid and Nitric acid solution with a water volume ratio of 1:1, 1 mol / L NaOH solution, and double-distilled aqueous solution were ultrasonically cleaned; acetone was analytically pure, and the nitric acid solution was a volume ratio of nitric acid to water of 1:1, and ultrasonically cleaned for 30 min , the ultrasonic condition was 40 kHz, 100 W, the glassy carbon electrode was used as the working electrode, the Ag / AgCl electrode was used as the reference electrode, and the platinum wire electrode was used as the auxiliary electrode.

[0033] After the graphene / magnetic nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com