Self-maintenance rolling bearing and assembling method thereof

A rolling bearing, bearing technology, applied in the direction of roller bearings, bearing components, shafts and bearings, etc., can solve problems such as increased design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

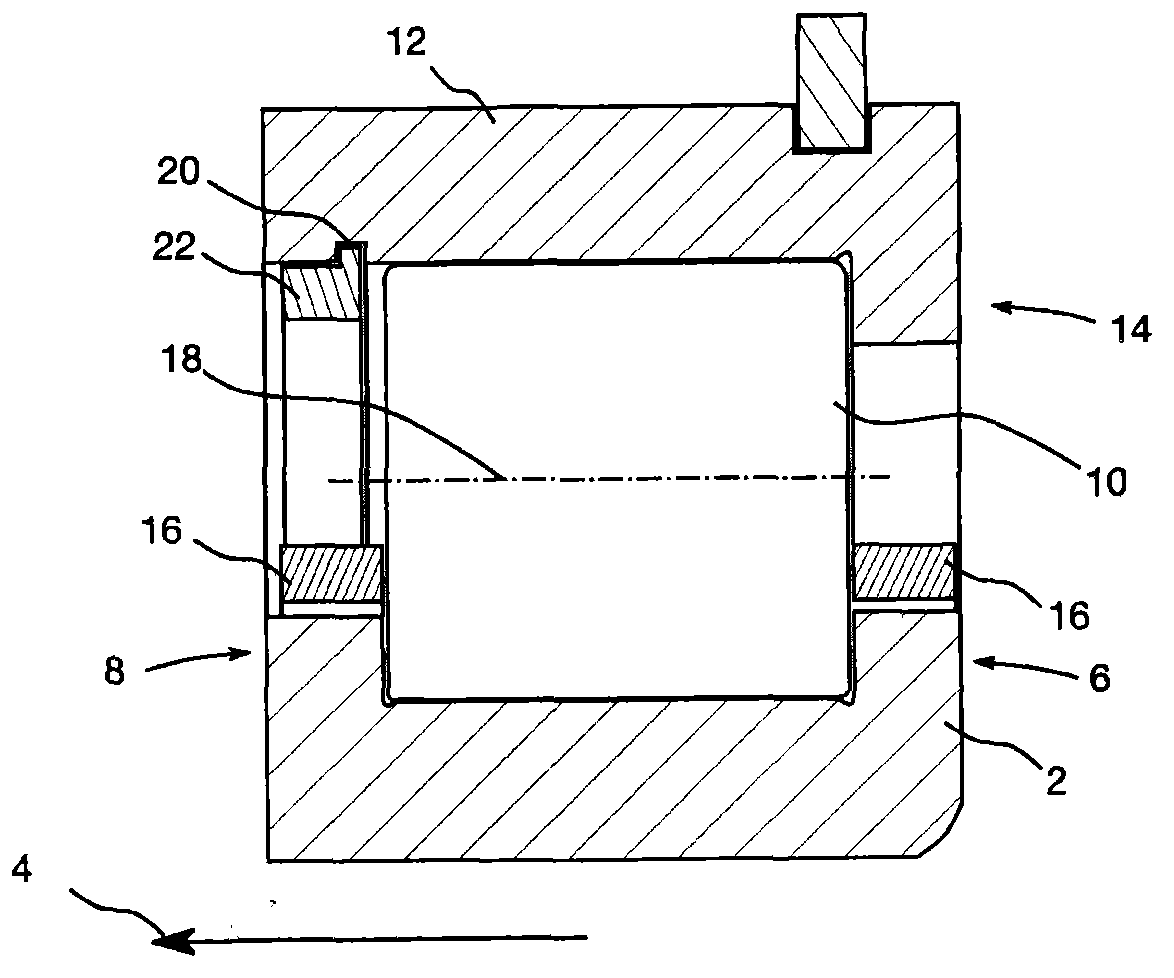

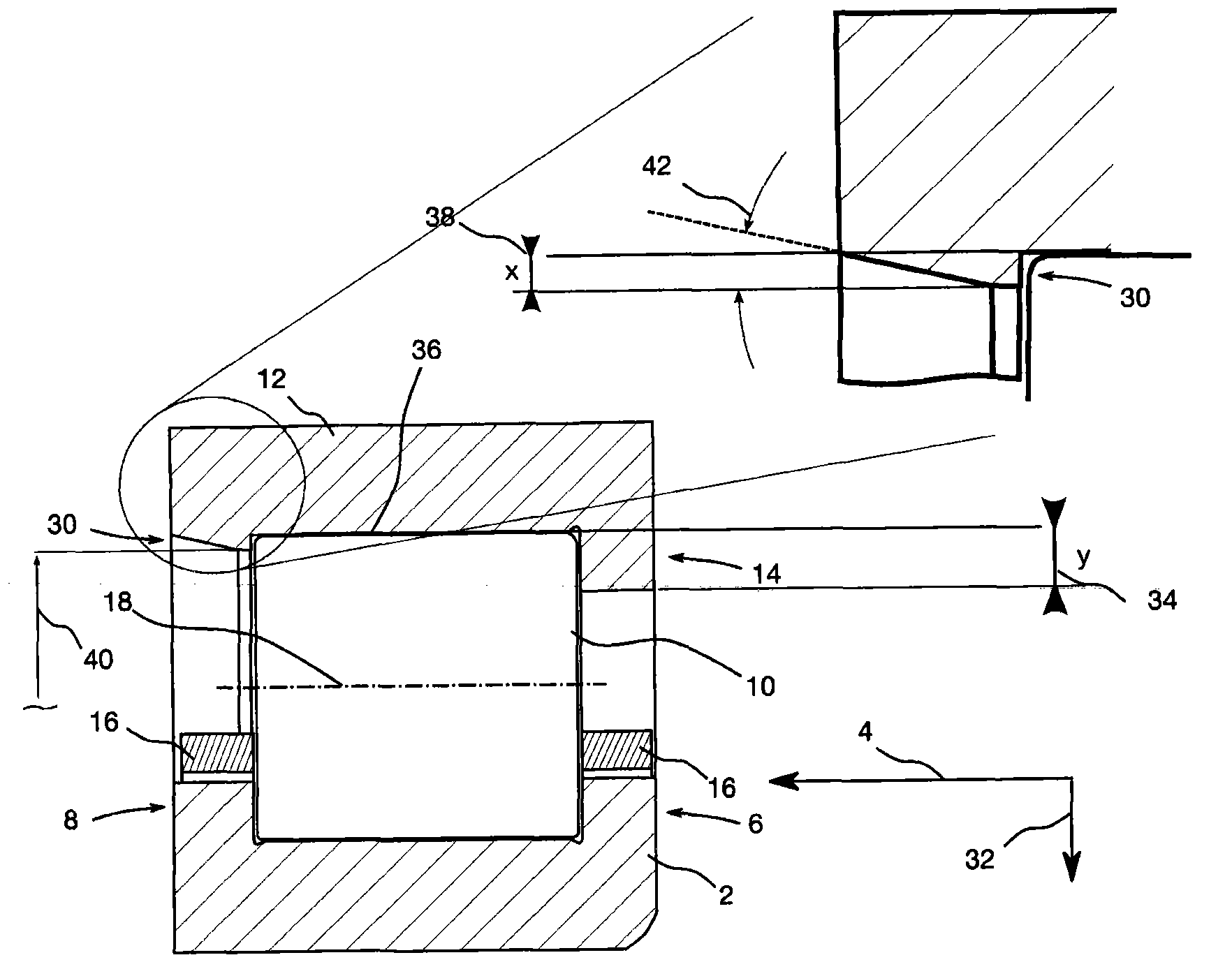

[0021] attached figure 1 Shown is a cross-sectional view of a conventional cylindrical roller bearing that utilizes a right-angle circlip to prevent disassembly. in the attached figure 1 In the case shown, the bearing inner ring 2 has not only a first rib 6 at the first end of its raceway, but also a second rib 8 at the opposite end of its raceway in the axial direction 4 . Rolling bodies or cylindrical rollers 10 are arranged within ribs 6 and 8 . The bearing outer ring 12 has a rib 14 only on the first axial end of its raceway, and no rib on the opposite end of the raceway, so that the bearing can be mounted or assembled. in the attached figure 1 In the example shown, the bearing cage 16 is guided below the pitch circle. Here, the ideal circle formed by the center of the cylindrical roller when the bearing rolls can be used as the pitch circle. The ideal radius of the pitch circle can thus be derived from the distance between the axis of symmetry 18 of the cylindrical r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com