Assembling machine for assembling gears, bearings and gear shafts

A gear shaft and assembly machine technology, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems that the transmission cannot be deeply understood by students, deviations are easy to occur, and mechanical assembly is not accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

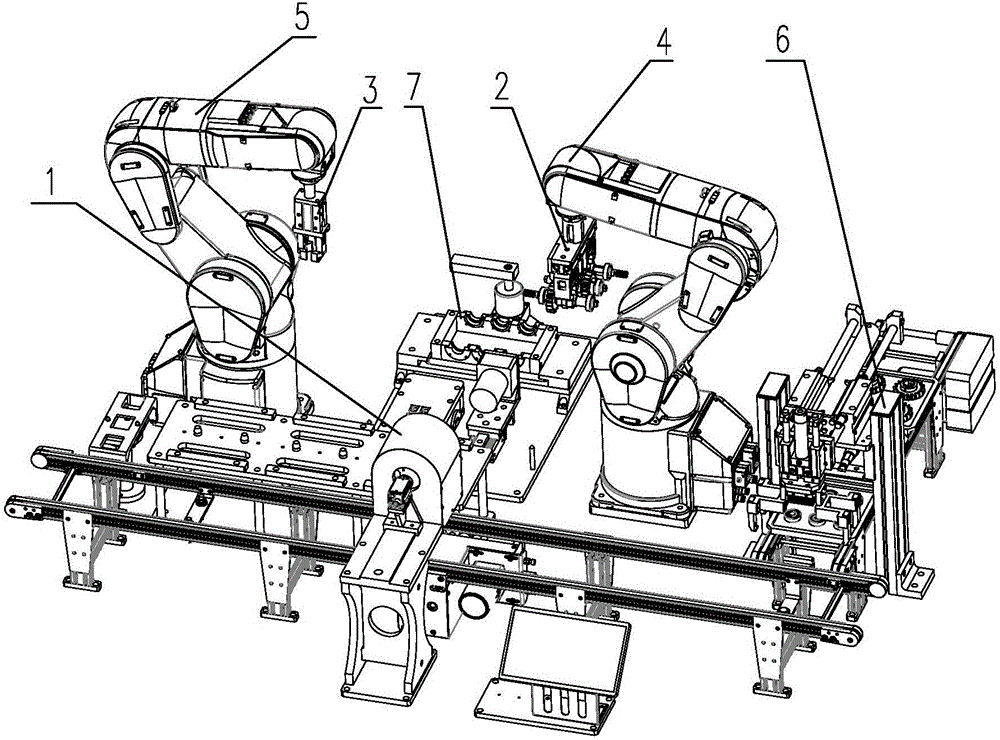

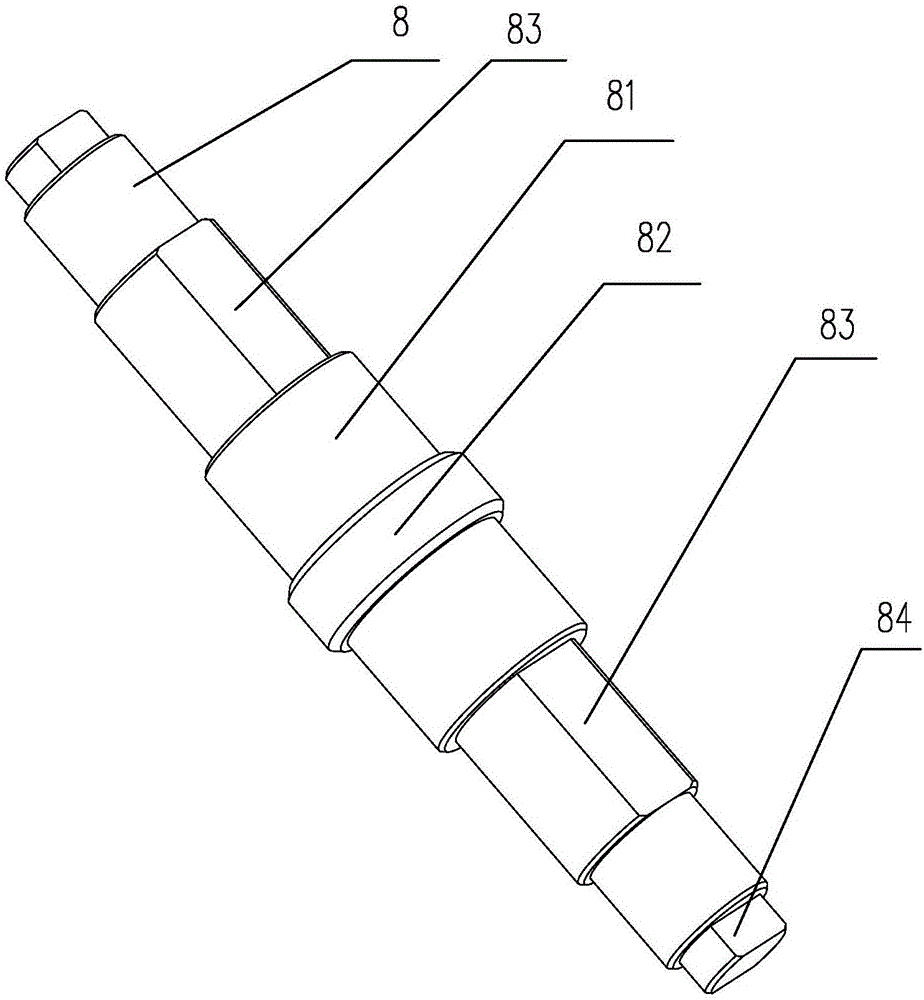

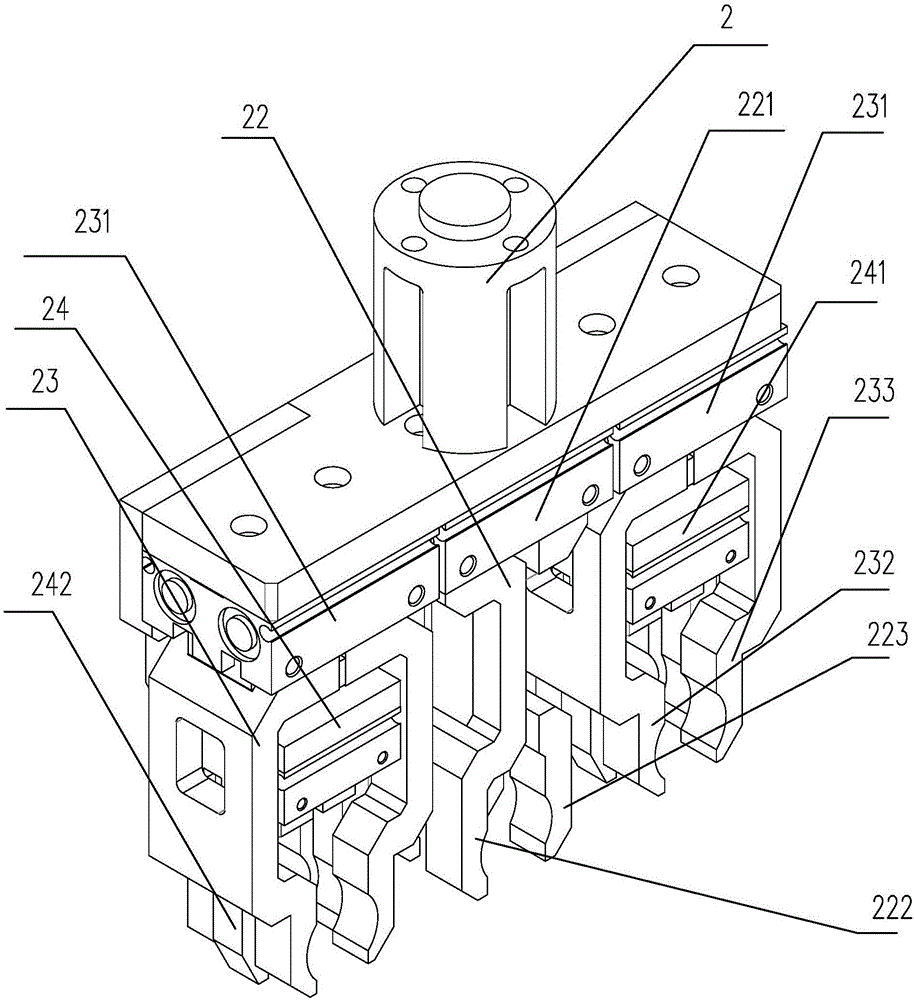

[0044] Depend on Figure 2 to Figure 19It can be seen that the present invention discloses an assembly machine for gears, bearings and gear shafts 8, including a transmission device 6 for transmitting gears, gear shafts 8, and bearings, and a first manipulator for clamping gear shafts 8, for The second manipulator that grips the gears and bearings and sets the bearings and gears on the corresponding gear shafts 8 controls the second manipulator to rotate on the other gear shafts 8 according to the position of the side plane of the bump 84 at the end of one of the gear shafts 8 The gear realizes the visual sensor 1 of the corresponding gear meshing on the adjacent gear shaft 8, and the first manipulator includes the first gripper 2 for clamping the three gear shafts 8 and the first gripper 2 for driving the first gripper 2 to grip the gear shaft 8. A mechanical arm 4, the first gripper 2 is provided with a central clamping unit 22 and side clamping units arranged on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com