Self-suction device with air exhausted in circulating mode

A self-priming device and self-control exhauster technology, which is applied in the direction of machines/engines, non-variable pumps, drive pumps, etc., can solve the problems of difficulty in grid connection, large volume and high cost of self-priming devices, and achieve a wide range of applications and volume Small, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

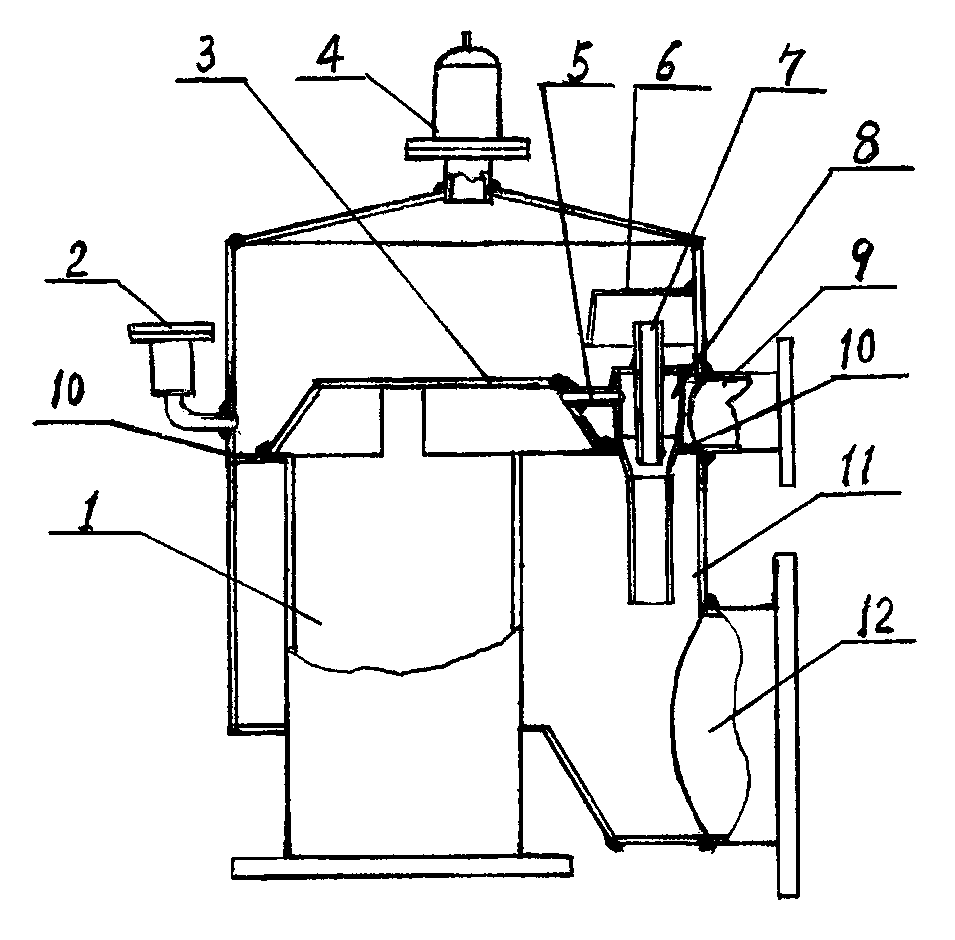

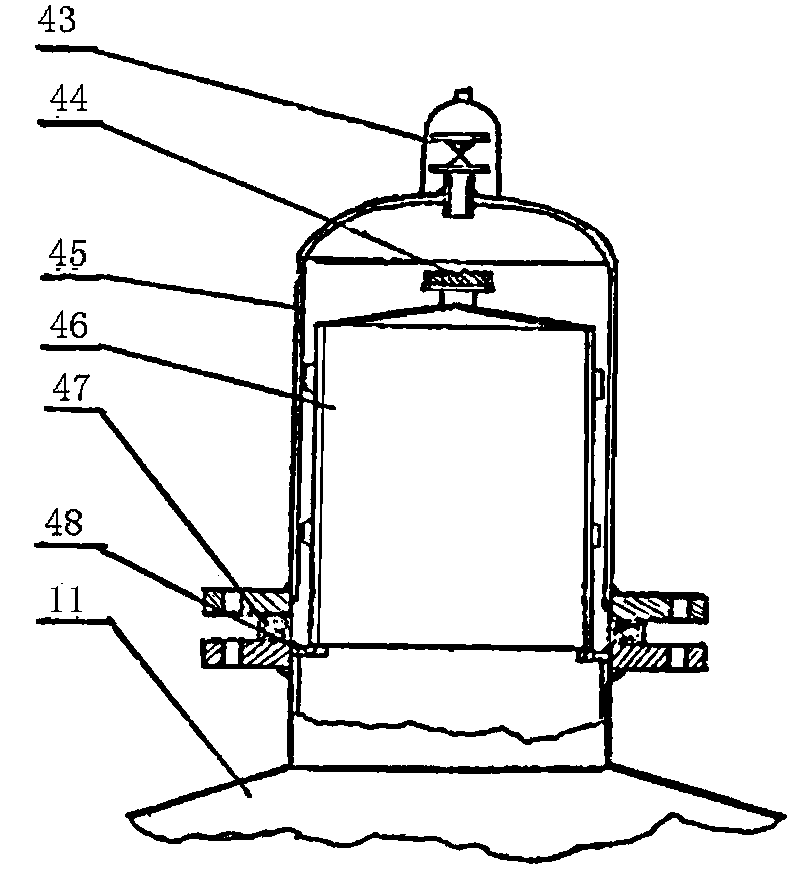

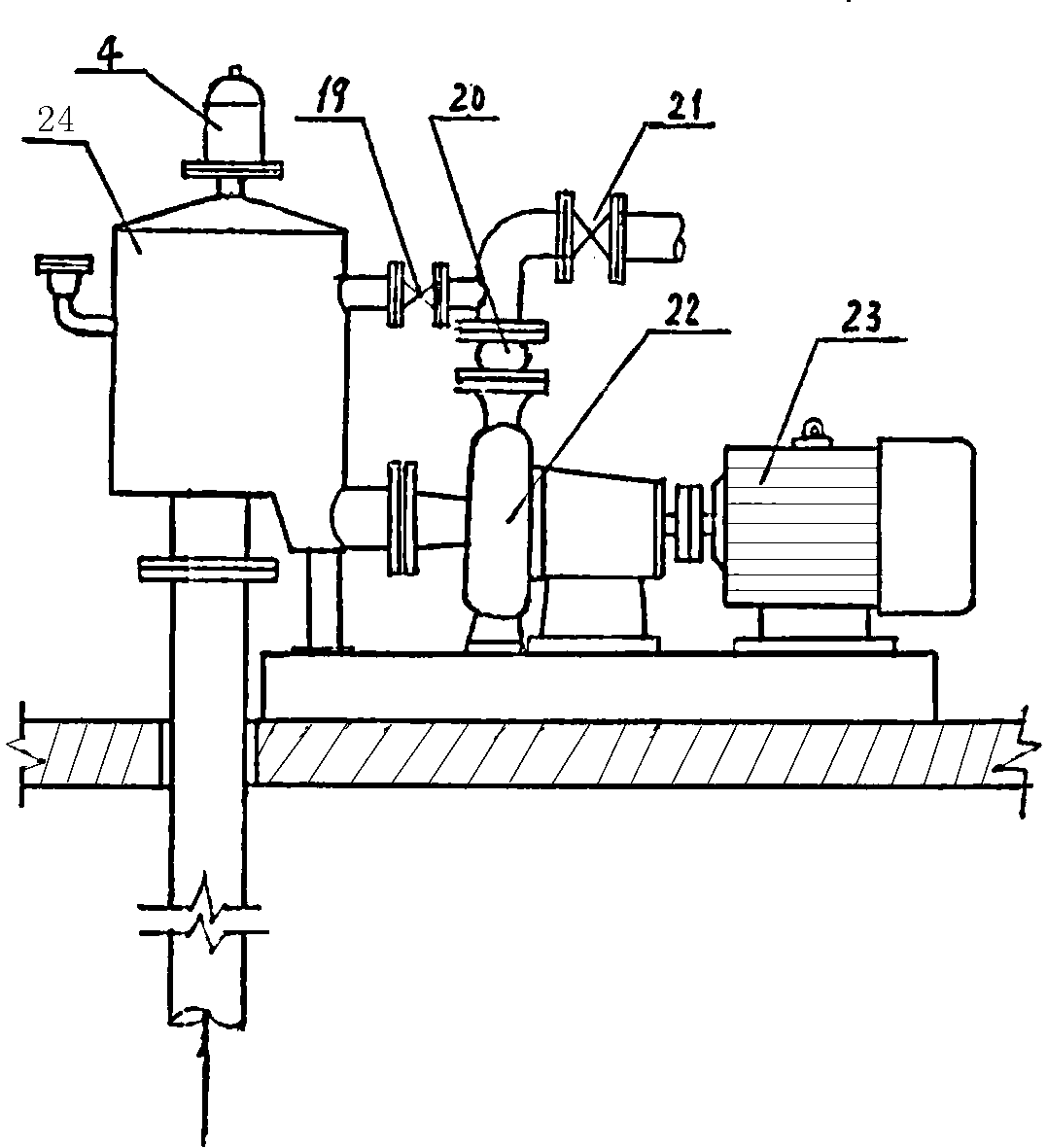

[0018] Such as figure 1 As shown, the circulating air exhaust self-priming device of the present invention includes a tank body 11, a water guide cap 3 and a partition 10 are arranged inside the tank body, and the water guide cap 3 and the partition plate 10 are welded to divide the tank body into upper and lower chambers , the top of the tank is equipped with a self-control air exhauster 4, the inside of the upper cavity of the tank is equipped with a return water windshield 6, the outer side of the upper cavity of the tank is connected with a water injection pipe gland 2, and the other side of the upper cavity of the tank is installed There is a circulating water inlet pipe 9, and a water outlet pipe 12 is arranged outside the lower chamber of the tank below the circulating water inlet pipe 9, and a water suction pipe 1 is arranged below the water guide cap 3, and the water suction pipe 1 passes through the air-inducing conduit 5 and the injector 8 Connected to each other, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com