Corrugated sheet steel composite structure bridge deck system

A technology of corrugated steel plates and composite structures, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of pedestrians or vehicles threats, concrete is easy to fall off, etc., and achieve a good diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

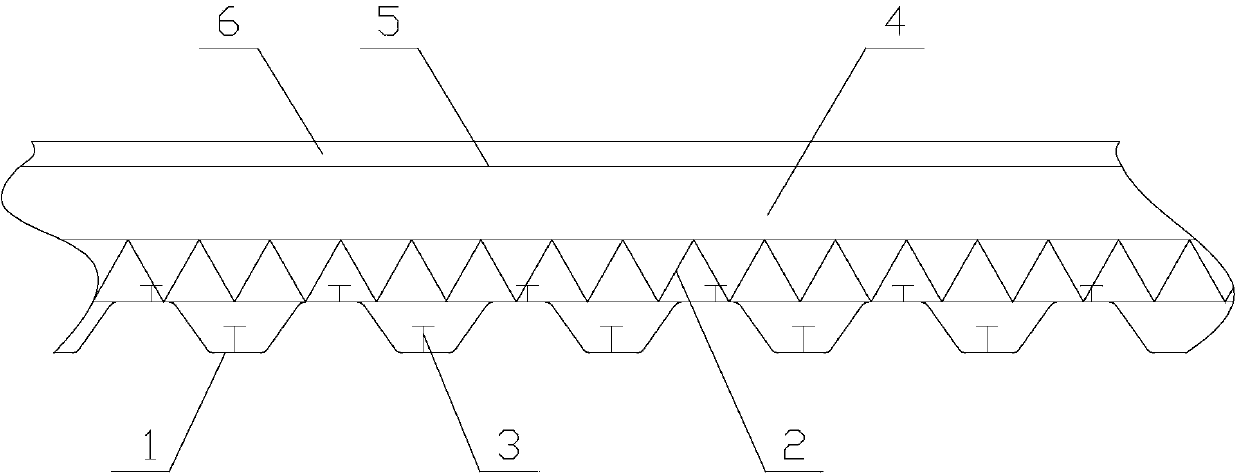

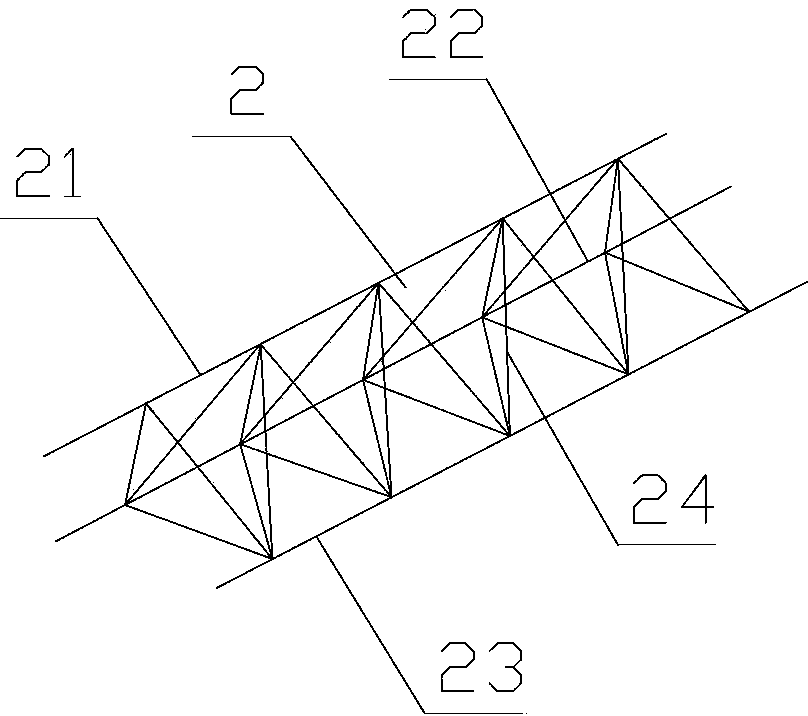

[0025] Corrugated steel plate composite structure bridge deck system, such as figure 1 , 2 , 3, 6, including a corrugated steel plate 1, the corrugated steel plate 1 is provided with a reinforcement skeleton 2 and a stud 4, and the reinforcement skeleton 2 and the stud 4 are poured into the concrete. The corrugated steel plate is also used as a formwork, and studs and triangular truss steel bars are welded on the top surface of the corrugated steel plate to increase the structural strength of the composite deck system. The corrugated steel plate is not only used as a stress-bearing member of the bottom plate, but also as a formwork, and has the advantages of low maintenance cost in the later period, less safety hazards in the use of the bridge, convenient construction, and good overall economy. When used as a stressed member of the bottom plate, it improves the connection strength between the corrugated steel bottom plate and concrete and has good shear resistance. At the sam...

Embodiment 2

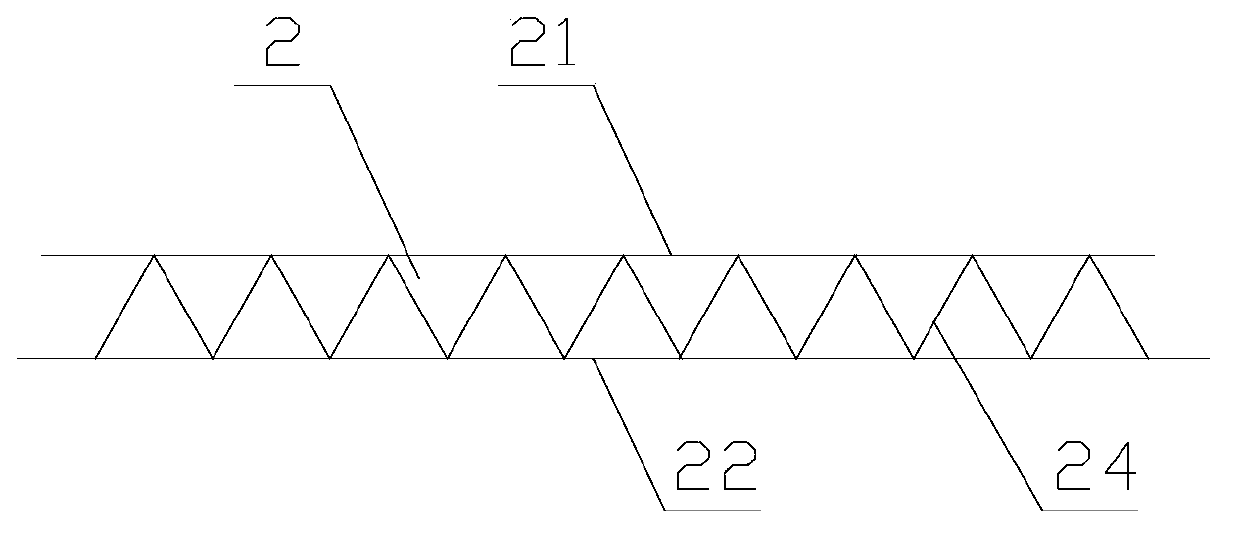

[0033] Corrugated steel plate composite structure bridge deck system, such as figure 2 , 3 , 4, 5, and 6, including a corrugated steel plate 1, the corrugated steel plate 1 is provided with a reinforcement skeleton 2 and a stud 4, and the reinforcement skeleton 2 and the stud 4 are poured into the concrete. The corrugated steel plate is also used as a formwork, and studs and triangular truss steel bars are welded on the top surface of the corrugated steel plate to increase the structural strength of the composite deck system. The corrugated steel plate is also used as a formwork, and studs and triangular truss steel bars are welded on the top surface of the corrugated steel plate to increase the structural strength of the composite deck system.

[0034] The reinforcement skeleton 2 is a reinforcement skeleton made of threaded steel bars, and the reinforcement skeleton is welded to the corrugated steel plate 1 . A steel wire mesh 5 is set on the reinforcement frame 2 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com