Split type composite fiber and superfine fiber fabric prepared by same

A technology of ultra-fine fiber fabric and composite fiber, which is applied in fiber processing, conjugated synthetic polymer rayon, filament/thread forming, etc. The effect of softening and eliminating fiber formation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

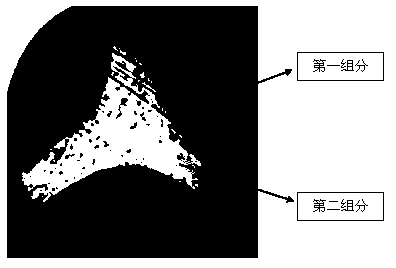

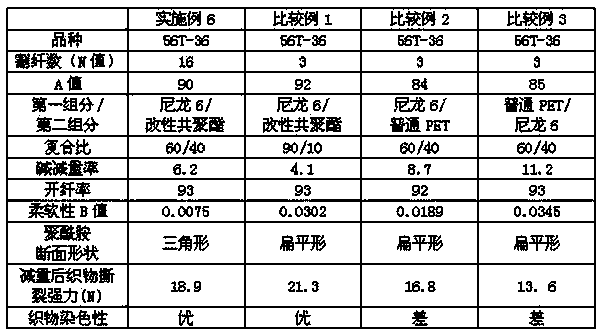

Embodiment 1

[0051] Pass the first component polyamide chips and the second component modified copolyester chips with moisture less than 100ppm after drying through the screw extruder, make them melted, flow into the metering pump, press them into the component after accurate metering, and spit out into filaments . Modified copolyester chips and nylon 6 chips are melted at 270°C and 255°C respectively, and are extruded into filaments through a specially designed 36-hole three-split spinneret. The composite ratio of nylon 6 and modified copolyester is 60:40, the take-up speed is 4000m / min, the temperature of the first hot roller is 70°C, the temperature of the second hot roller is 160°C, the first hot roller and the second hot roller The magnification between the hot rollers is 1.5, and the denier of the spun raw yarn is 56.0 dtex. The modified copolyester shows a continuous distribution on the cross section of the raw yarn, and the nylon 6 shows a discontinuous distribution state of three ...

Embodiment 2

[0057] Except that the composite ratio of nylon 6 and modified copolyester was adjusted to 80:20, other conditions were the same as in Example 1. See Table 1 for the results and dyeing results of fabrics made from this fiber after weight reduction.

Embodiment 3

[0059] Except that the composite ratio of nylon 6 and modified copolyester was adjusted to 40:60, other conditions were the same as in Example 1. See Table 1 for the results and dyeing results of fabrics made from this fiber after weight reduction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com