Gelatin and preparation method thereof

A technology of gelatin and gelatin solution, applied in the preparation of animal glue or gelatin, food preparation, food science, etc., to achieve low ash content and prevent dehydration condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

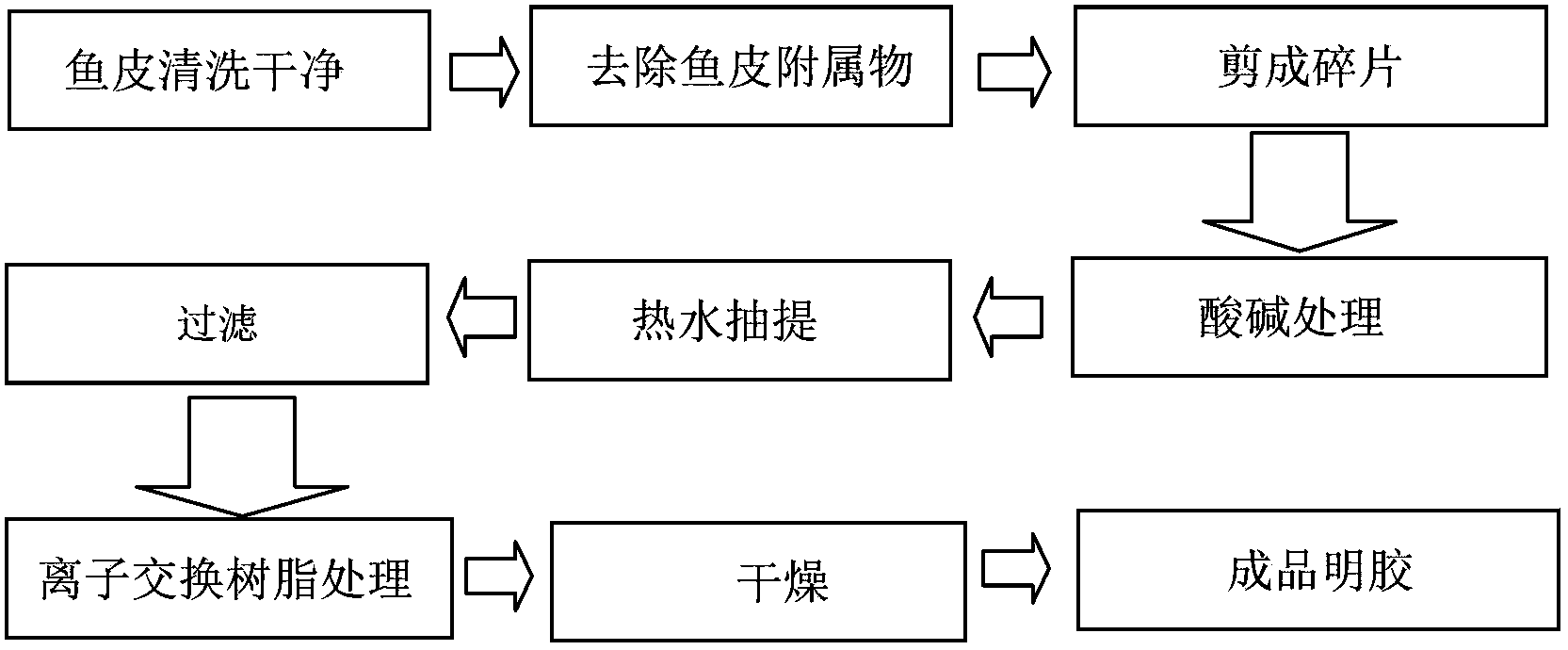

[0042] The invention provides a preparation method of gelatin, which comprises the following steps of acid-base treatment, hot water extraction, purification and drying. Optionally, a chopping step is also included before the acid-base treatment step. Optionally, a washing step is also included prior to the chopping step. Preferably, the preparation method of the present invention sequentially includes a cleaning step, a chopping step, an acid-base treatment step, a hot water extraction step, a purification step, and a drying step.

[0043] In the cleaning step of the present invention, the skin of the cold-water fish is cleaned, and the fat and fish meat on the surface are removed. Preferably, wash with cold water. The temperature of cold water is preferably 0 to 10°C, more preferably 5 to 8°C. In the cleaning step of the present invention, it is preferred to: use cold water to clean the fish skin; use petroleum ether to carry out reflux degreasing to the fish skin, the re...

Embodiment 1

[0090] Such as figure 1 As shown, taking salmon skin as an example to prepare cold-water fish gelatin as a raw material, the following process steps are performed in sequence:

[0091] Step 1: Thaw the salmon skin and wash it with cold water to remove the sticky fat and fish meat on the surface;

[0092] Step 2: Mince the cleaned salmon skin into 2 pieces of fish skin;

[0093] Step 3: Clean the fish skin fragments, and use 10mL Ca(OH) per 1g fish skin 2 Proportion of solution: Add calcium hydroxide solution with a concentration of 0.12wt% to the fish skin, soak at 10°C for 8 hours, rinse the fish skin after alkali treatment with cold water, and add 10 mL of HCl solution per 1 g of fish skin to the fish skin Add a hydrochloric acid solution with a concentration of 0.1wt%, soak for 1h;

[0094] Step 4: Wash the fish skin after the acid-base treatment until neutral, add water to the fish skin at a ratio of 3 mL of deionized water per 1 g of fish skin, and extract at 50°C for ...

Embodiment 2

[0099] Taking cod skin as an example to prepare fish gelatin as a raw material, the following process steps are carried out in sequence:

[0100] Step 1: Thaw the cod skin and wash it with cold water to remove the sticky fat and fish meat on the surface;

[0101] Step 2: Mince the cleaned cod skin into 2 pieces of fish skin;

[0102] Step 3: Clean the fish skin fragments, add 0.2wt% sodium hydroxide solution to the fish skin at a ratio of 10 mL NaOH solution per 1 g fish skin, soak at 10°C for 6 hours, and rinse the fish skin after alkali treatment with cold water Clean, add a hydrochloric acid solution with a concentration of 0.12wt% to the fish skin at a ratio of 10 mL of hydrochloric acid solution per 1 g of fish skin, and soak for 0.5 h;

[0103] Step 4: Wash the fish skin after the acid-base treatment to neutrality, add water to the fish skin at a ratio of 3 mL of deionized water per 1 g of fish skin, and extract at 45° C. for 3 hours;

[0104] Step 5: the filtered gela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com