Method for preparing epoxy resin by heavy-phase materials in cardanol production

A technology of epoxy resin and heavy phase material, applied in the field of chemistry, can solve the problems of low use efficiency of heavy phase, unstable quality, many unknown impurities, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

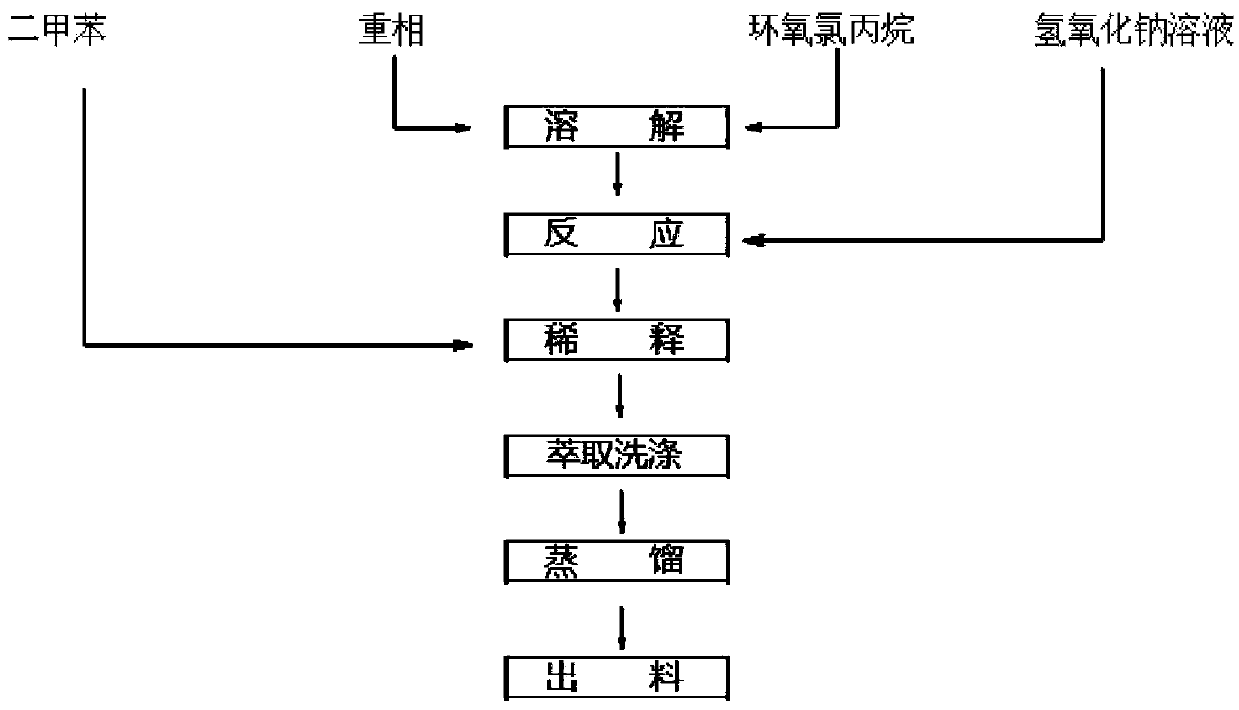

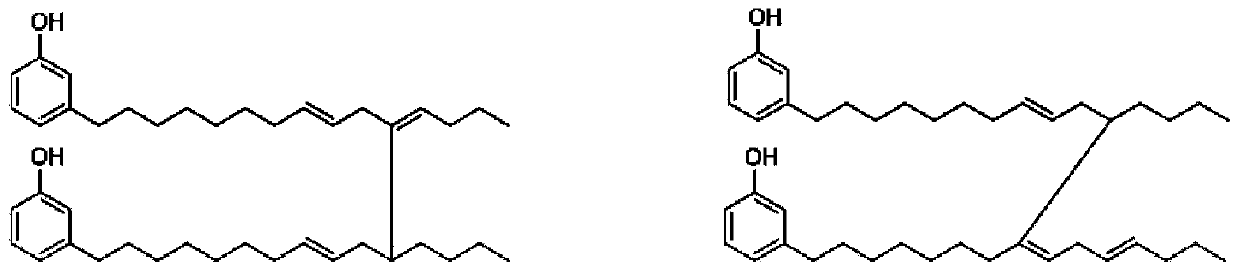

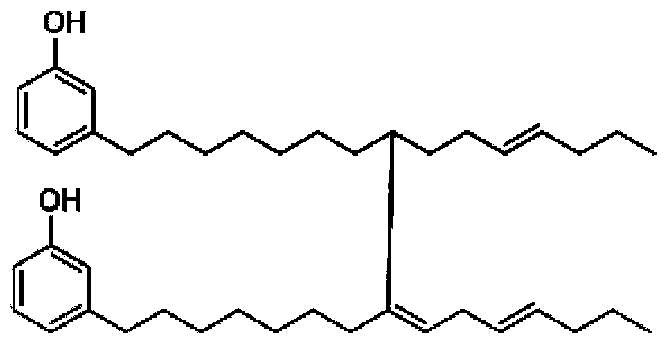

[0034] Such as figure 1 As shown, the present invention utilizes the cardanol heavy phase material in the production of cardanol to prepare epoxy resin method (1), according to the cardanol heavy phase material: epichlorohydrin: the molar ratio of strong base=1:1~ 10: The mass of 1-10 weighs each material, and the molar number of the cardanol heavy phase material is calculated according to the phenolic hydroxyl group in the cardanol heavy phase material, and then the cardanol heavy phase material is added into the reaction vessel, stirred, Introduce nitrogen to exhaust the air, then add epichlorohydrin after 1-5 minutes, continue to stir, control the temperature at 40-50 degrees Celsius, add strong alkali solution, raise the temperature to 70-100 degrees Celsius after the dropwise addition, and keep warm for 2-9 hours , add an organic solvent until all the above-mentioned substances dissolve into a uniform liquid, then wash with hot water for 3-8 times, the temperature of the ...

Embodiment 2

[0040]Method for preparing epoxy resin by using cardanol heavy phase material in cardanol production (2) Add cardanol heavy phase material (300g) and epichlorohydrin (138.78g) into a four-necked bottle, pass nitrogen protection, and raise the temperature to 45 degrees Celsius, and then slowly add a strong alkali aqueous solution (1mol) with a mass percentage concentration of 50% under stirring, so that the temperature is always controlled below 70 degrees Celsius, and after the addition is completed, stir at 75 degrees Celsius for 2-9 hours, add Dilute with solvent until the above substances are all dissolved into a uniform liquid, then wash with hot water for 3-8 times, and distill under reduced pressure to obtain a black oily liquid, which is the prepared product. The solid content of the obtained product is 90-100%, and the viscosity is 200 ~580000mPa.S (25℃), epoxy value 0.10~0.35eq / 100g.

[0041] Further, the organic solvent is xylene, toluene or methanol.

[0042] Furth...

Embodiment 3

[0045] Through curing with MD1041 produced by Shanghai Meidong Biomaterials Co., Ltd., it is found that compared with bisphenol A epoxy resin E20, the above product has no decline in performance except for the darker color. For example, in terms of hardness, E20 is the same as Shanghai Meidong The Shore hardness of MD1041 produced by East Biomaterials Co., Ltd. is 10-20 after curing, and the product with an epoxy value of 0.20 and epoxy resin curing agent MD1041 has a Shore hardness of 15-30 after curing. The test condition is that the resin and curing agent are evenly mixed and cured at room temperature (25°C) for 7 days.

[0046] Wherein the cardanol heavy phase material epoxy basic data used are as follows:

[0047] project

[0048] Cardanol heavy phase epoxy and MD1041 basic data after curing:

[0049] project

[0050] Matching ratio

[0051] The Shore hardness is 23 after being cured with the same ratio as MD1041. Compared with epoxy resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com