Method for separating and purifying chlorogenic acid by utilizing temperature to induce aqueous two-phase system

A two-phase system, temperature-induced technology, applied in the separation/purification of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of difficult polymer recovery, hindering the application of two-phase technology, etc., To achieve the effect of environmental protection, short time consumption and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Extraction of crude chlorogenic acid: crush 1.5 kg of Eucommia ulmoides leaves, put them into an extraction tank, add 10 L of water, heat to reflux for 2 hours, and concentrate to an extract, which is crude chlorogenic acid with a content of 13.37%.

[0021] 2) Two-phase aqueous phase separation: prepare EOPO / salt two-phase aqueous system, in which EOPO (molecular weight: 2000) is 10 mL, water is 15 mL, and the concentration of dipotassium hydrogen phosphate is 0.1 g / mL. Add 100 mg of crude chlorogenic acid to the aqueous two-phase system, mix well, and centrifuge at 2000 r / min for 3 minutes to separate the organic phase (rich in EOPO) and the aqueous phase, and the chlorogenic acid is enriched in the organic phase (upper phase ), impurities are enriched in the aqueous phase.

[0022] 3) Temperature-induced aqueous two-phase separation: The organic phase (rich in EOPO) was subjected to temperature-induced phase separation. After 20 minutes in a water bath at 60°C, t...

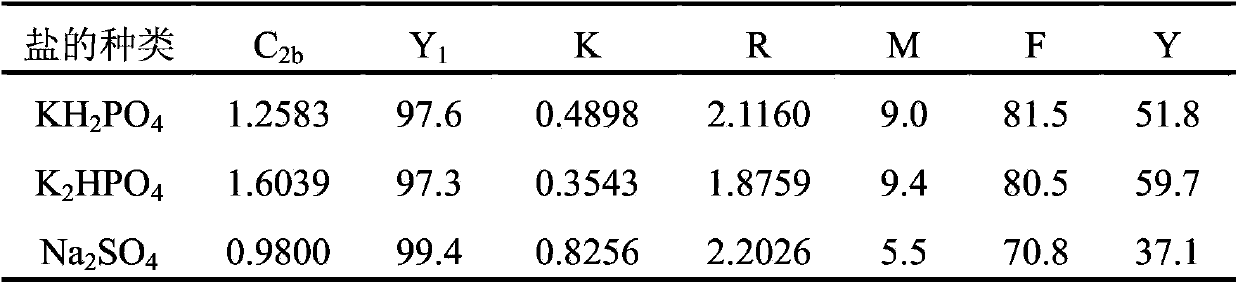

Embodiment 2

[0035] 1) Extraction of crude chlorogenic acid: crush 1.5 kg of Eucommia ulmoides leaves, put them into an extraction tank, add 10 L of water, heat to reflux for 2 hours, and concentrate to an extract, which is crude chlorogenic acid with a content of 13.37%.

[0036] 2) Two-phase aqueous phase separation: prepare EOPO / salt two-phase aqueous system, in which EOPO (SDP35, molecular weight 2750) 10mL, water 15mL, and salt are respectively selected from KH 2 PO 4 、K 2 HPO 4 、Na 2 SO 4 , NH 4 Cl, the concentration is 0.1g / mL respectively. Add 100 mg of crude chlorogenic acid to the two-phase aqueous system, mix well, and centrifuge at 2000 rpm for 3 minutes to separate the organic phase (rich in EOPO) and the aqueous phase, and the chlorogenic acid is enriched in the organic phase (top phase), impurities are enriched in the aqueous phase.

[0037] 3) Temperature-induced aqueous two-phase separation: The organic phase (rich in EOPO) was subjected to temperature-induced phase...

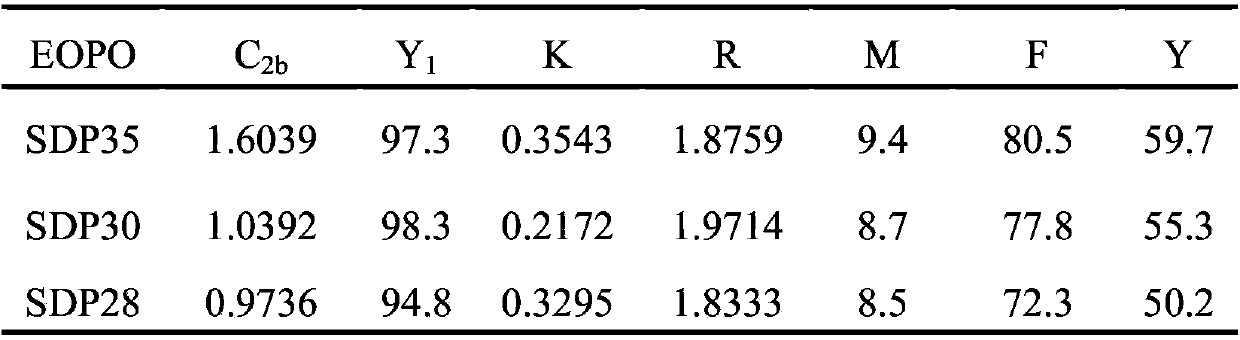

Embodiment 3

[0043]1) Extraction of crude chlorogenic acid: crush 1.5 kg of Eucommia ulmoides leaves, put them into an extraction tank, add 10 L of water, heat to reflux for 2 hours, and concentrate to an extract, which is crude chlorogenic acid with a content of 13.37%.

[0044] 2) Two-phase aqueous phase separation: Prepare EOPO / salt two-phase aqueous system, in which EOPO (SDP35, molecular weight 2750) 5, 10, 15mL, water 10, 15, 20mL, dipotassium hydrogen phosphate 1.0, 1.5, 2.0g. Add 100 mg of crude chlorogenic acid to the aqueous phase system, mix well, and centrifuge at a speed of 2000r / min for 3 minutes to separate the organic phase (rich in EOPO) and the aqueous phase, and the chlorogenic acid is enriched in the organic phase (upper phase). Impurities are enriched in the aqueous phase.

[0045] 3) Temperature-induced aqueous two-phase separation: The organic phase (rich in EOPO) was subjected to temperature-induced phase separation. After 20 minutes in a water bath at 60°C, the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com