In-situ water repair method for clean aquaculture

An in-situ restoration and aquaculture technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., to achieve in-situ purification and discharge of pollutants up to standard, cost saving, and validity period long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

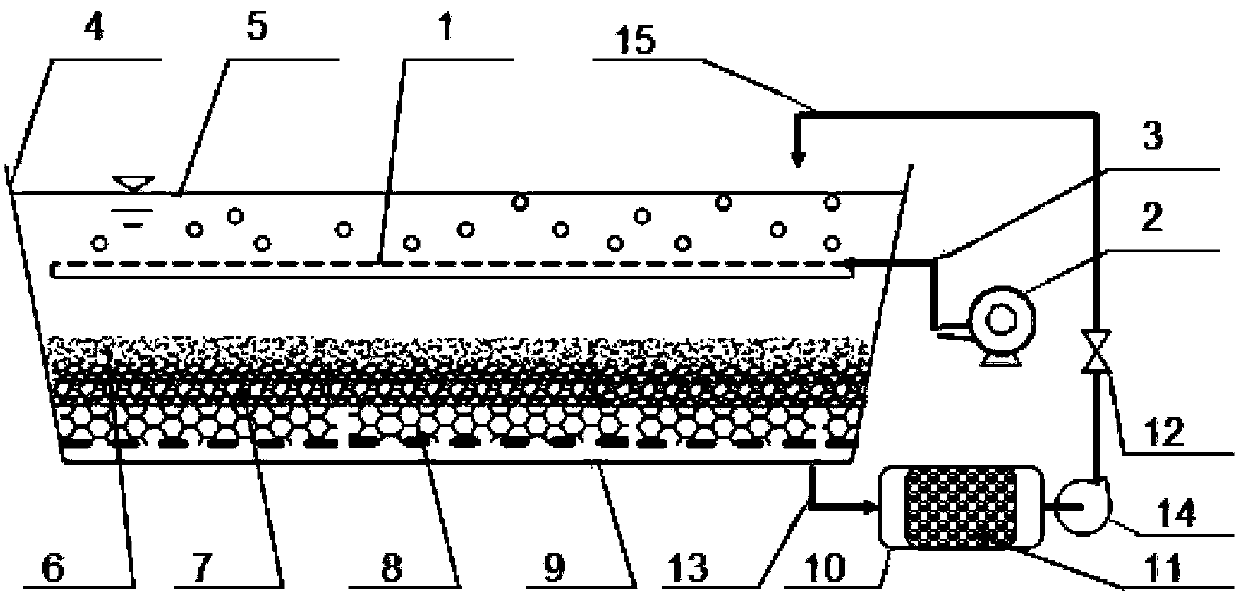

[0017] The applicant used the technology of the present invention to carry out a simulated application test of seawater aquaculture water restoration. The body of the pond is set vertically with a PVC pipe of Φ0.2×1.8m. The depth of the water body in the upper half of the pipe is 1.1m, and the height of the ecological infiltration layer in the lower half is 0.6m. The fillers from top to bottom are: the height of the fine sand layer is 0.15m, and the particle size range is 0-0.004m; the height of the gravel layer is 0.25m, and the particle size range is 0.01-0.04m; The two spheres are mixed in half and filled.

[0018] Using sea crystals and protein-rich bait to simulate the preparation of polluted mariculture water is driven by the liquid level difference. After the reactor water inlet control valve and circulating water pump are turned on, the polluted seawater passes through the fine sand layer and gravel layer from top to bottom. , The biochemical ball layer enters the sum...

Embodiment 2

[0022]The applicant used the technology of the present invention to carry out the simulated application test of freshwater aquaculture water restoration. The pond body, water body depth, composition, particle size and height of the percolation layer are all the same as in Example 1.

[0023] After the tap water is exposed to the sun to remove residual chlorine, it is used as freshwater aquaculture water. According to the main pollution situation when the aquaculture water comes, the bait with rich protein content is added to prepare the simulated pollution source.

[0024] COD of polluted water Cr The concentration is 250mg / L, and the concentration of ammonia nitrogen is 15mg / L.

[0025] The process and process parameters of the restoration of the aquaculture water body are the same as those in Example 1. After 8 hours of continuous operation, COD Cr The concentration is 20mg / L, and the concentration of ammonia nitrogen is 0.3mg / L. Respectively meet the "Freshwater Pond A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com