Porous carbon material and preparation method and application thereof

A technology of porous carbon and raw materials, which is applied in the preparation/purification of carbon, capacitors, structural parts, etc., can solve the problems of waste, pollution of environmental resources, etc., and achieve the effects of low cost, high specific surface area, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

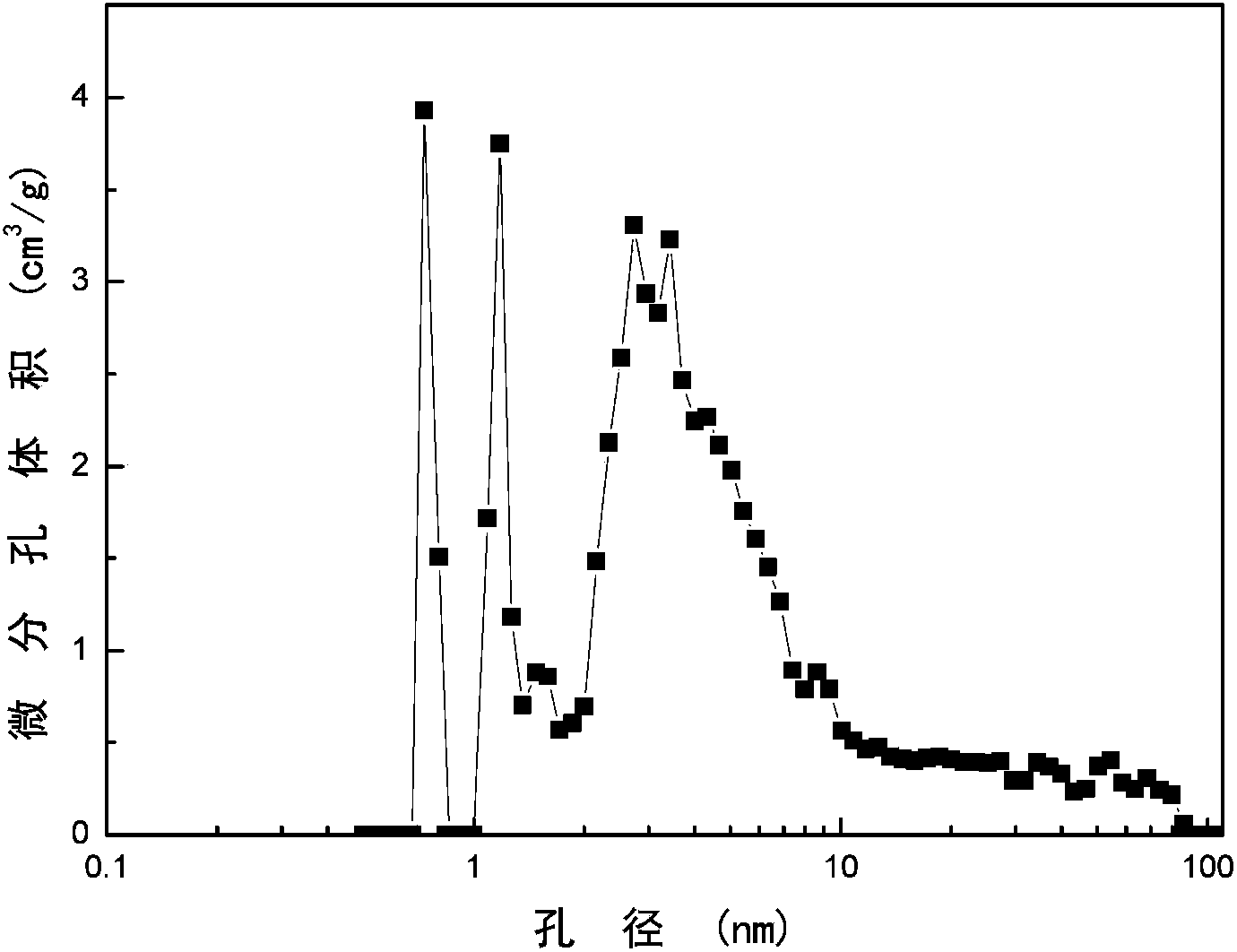

Embodiment 1

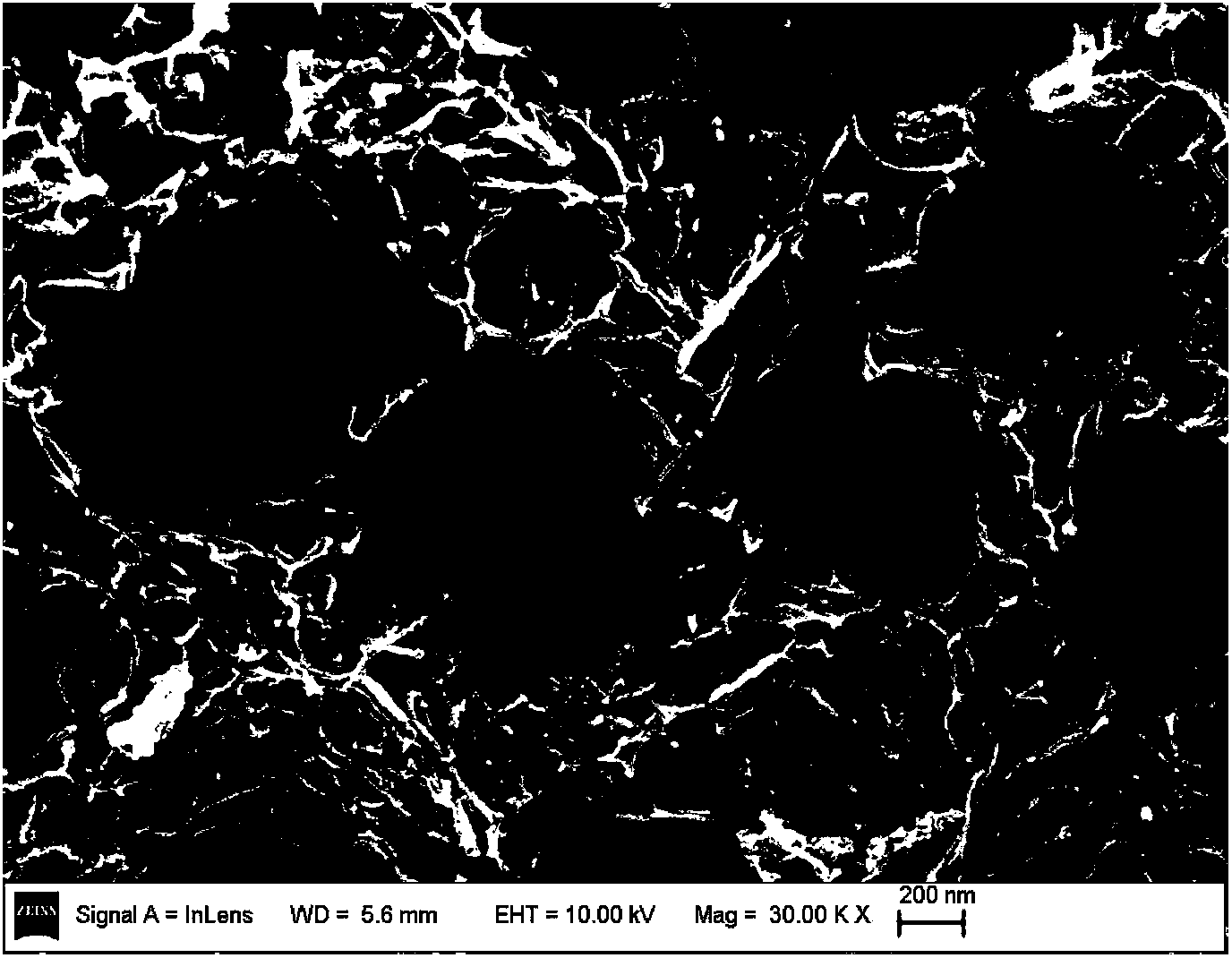

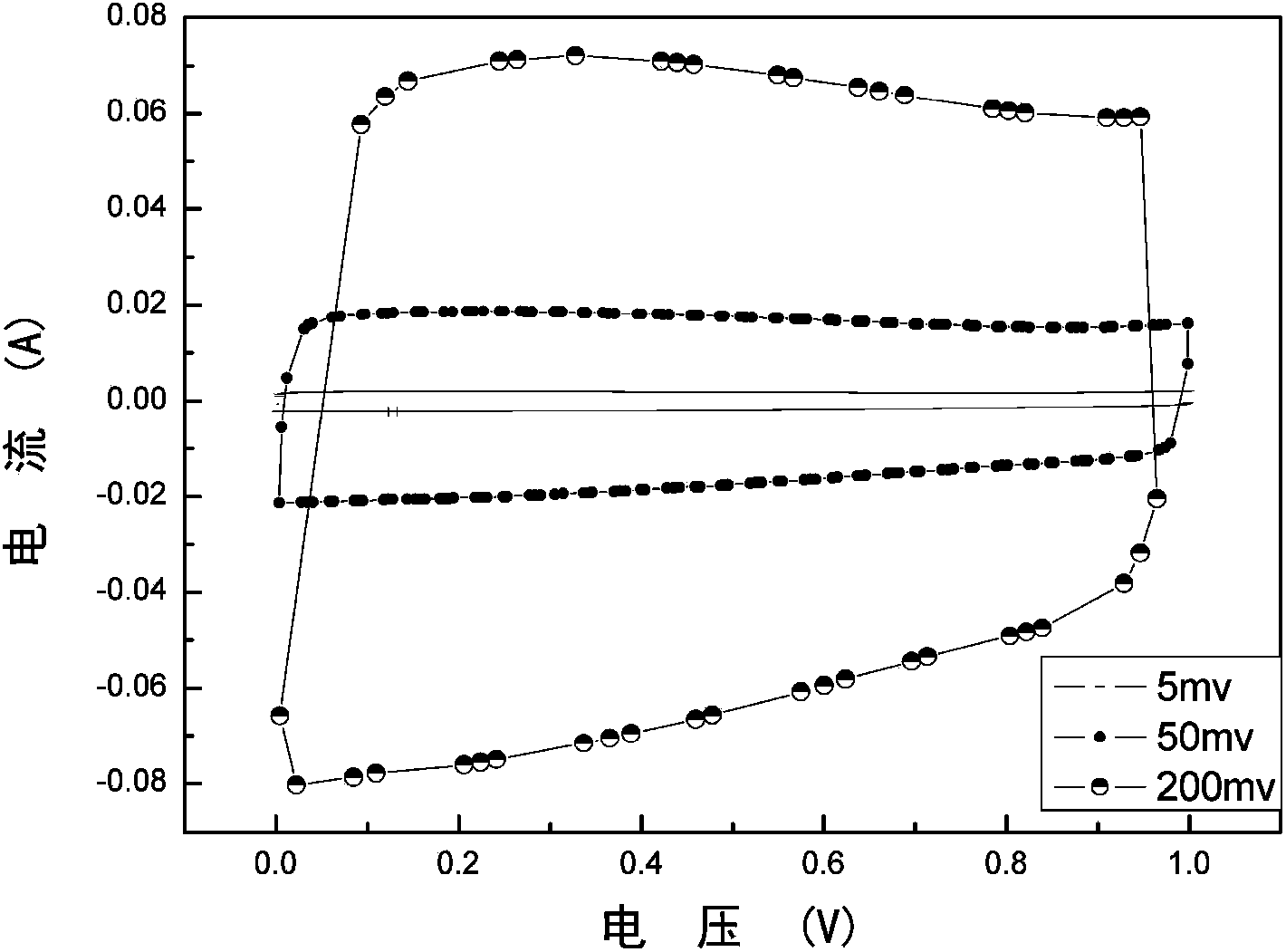

[0029] The cleaned crab shells were dried in an oven at 110°C, and then under the protection of nitrogen, the temperature was raised to 400°C in a tube furnace at a rate of 3°C / min and kept for 2 hours for pre-carbonization to obtain the precursor; the precursor Mix evenly with potassium hydroxide at a mass ratio of 1:1, raise the temperature to 900°C at a rate of 3°C / min in a tube furnace under nitrogen protection, and keep it for 1h. The above product was naturally cooled to room temperature under the protection of nitrogen, washed with 2mol / L HCl to remove the inorganic components, then washed with deionized water at 100°C until neutral, and dried at 120°C for 12h to obtain a porous carbon material. The BET specific surface area test method is used to test the porous carbon material, and its BET specific surface area reaches 3023m 2 / g, total pore volume 2.71cm 3 / g, adopting X-ray energy spectrum to measure its nitrogen element content is 0wt%. The pores are three-dimens...

Embodiment 2

[0031] Pre-carbonization is the same as in Example 1. The precursor and potassium hydroxide were uniformly mixed at a mass ratio of 1:0.5, then the temperature was raised to 900 °C at a rate of 3 °C / min under the protection of nitrogen, and kept for 1 h, and then naturally cooled to room temperature under the protection of nitrogen. The resulting product was treated with 2mol / L of HNO 3 Remove the inorganic components therein, wash with deionized water at 100°C until neutral, and dry at 120°C for 12 hours to obtain a porous carbon material. The BET specific surface area of the above porous carbon material is 2623m 2 / g, the total pore volume is 2.37cm 3 The porous carbon material of the three-dimensional pore distribution of / g adopts X-ray energy spectrum to measure its nitrogen content to be 0wt%.

Embodiment 3

[0033] Pre-carbonization is the same as in Example 1. The precursor and potassium hydroxide were uniformly mixed at a mass ratio of 1:1, then the temperature was raised to 600 °C at a rate of 3 °C / min under the protection of nitrogen, and kept for 1 h, and then naturally cooled to room temperature under the protection of nitrogen. Then the resulting product was treated with 2mol / L HNO 3 The inorganic components were removed, washed with deionized water at 100°C until neutral, and dried at 120°C for 12 hours to obtain a nitrogen-containing porous carbon material. The BET specific surface area of the above porous carbon material is 1158m 2 / g, the total pore volume is 0.91cm 3 / g of porous carbon material with three-dimensional pore distribution, and its nitrogen content is 6.79wt% as measured by X-ray energy spectroscopy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com