Oily sewage filter and filtering method

A sewage filter and filter material technology, which is applied to chemical instruments and methods, fixed filter element filters, filter circuits, etc., can solve the problems of filter material replacement, reduced treatment effect, and high operating costs, so as to reduce backwash water The effect of increasing the dosage, improving the regeneration effect, and reducing the operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

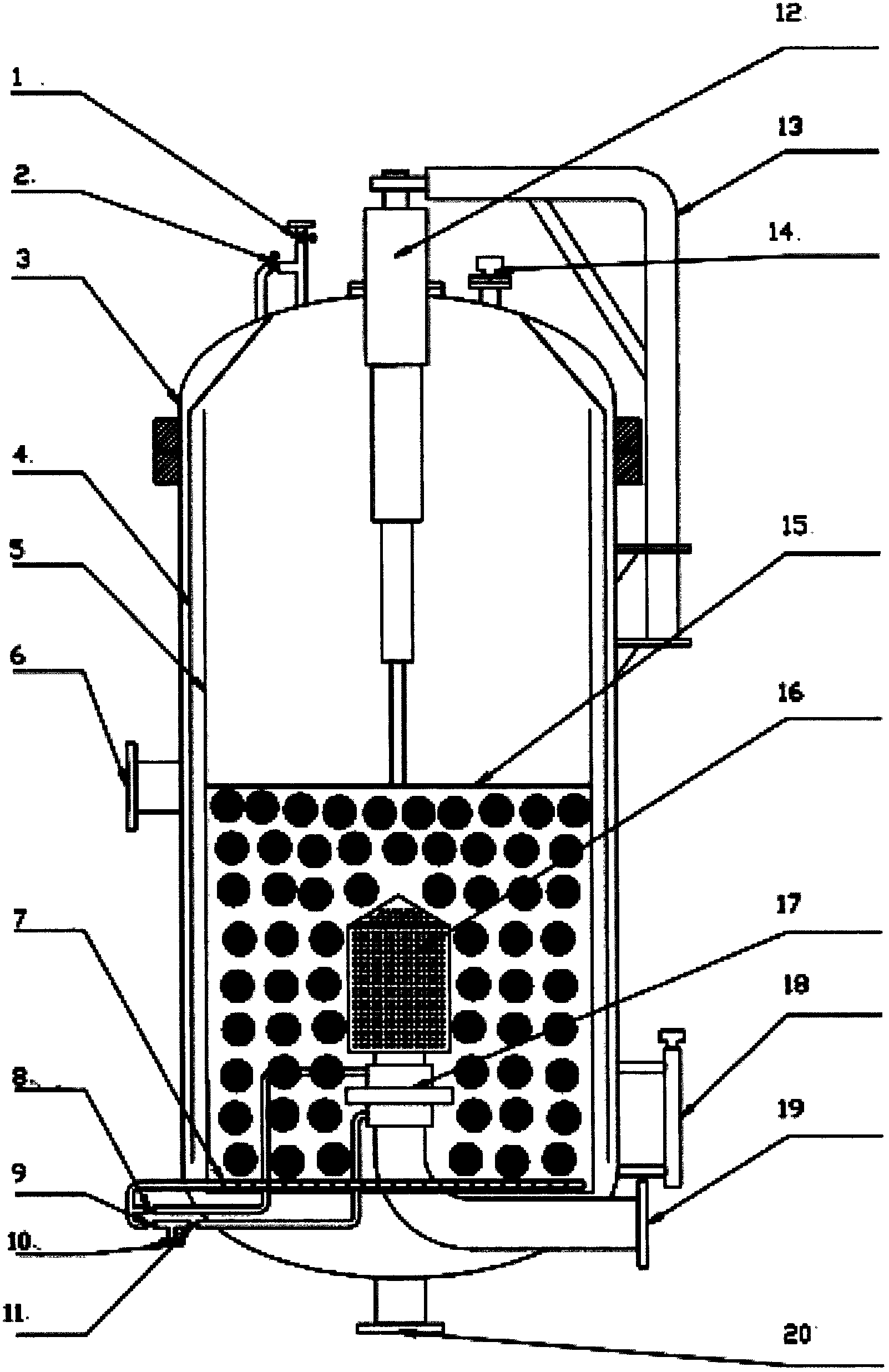

[0026] The oily sewage filter and the oily sewage filtering method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] As shown in the figure, the oily sewage filter of the present invention includes a tank body 3 and a water inlet 6 arranged in the middle of the tank body, an interface instrument 14 is arranged above the tank body 3, and a liquid level gauge 18 is arranged below the tank body; The inside of the tank body 3 is provided with a swirl partition 4 forming an annular swirl area with the side wall of the tank body. The inside of the swirl partition 4 is provided with a perforated net 5 forming a filter material filling area. The perforated pressure plate 15 that can divide the filter material filling area into upper and lower parts, the upper part of the filter material filling area and the upper part of the swirling flow area are oil slick accumulation areas, and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com