Processing method for high-gel active soybean protein

A processing method and a technology of soybean protein isolate, which are applied in the processing field of high-gel activity soybean protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 basic preparation process

[0028] A processing method of high gel activity soybean protein isolate, the steps are as follows:

[0029] (1) Adopt commercially purchased soy protein isolate (purchased from Yuwang Company, Shandong Province) as raw material;

[0030] (2) Soybean protein isolate powder is dissolved in distilled water, and the dissolving ratio is that 10g soybean protein isolate powder is dissolved in 100 milliliters of distilled water, is made into soybean protein isolate solution;

[0031] (3) Stir the soy protein isolate solution at 25° C. with a magnetic stirrer for 3 hours;

[0032] (4) Soybean protein isolate solution after stirring is immersed in ice bath for 10min;

[0033](5) The soybean protein isolate solution of step 4) is ultrasonically treated with a 20kHz ultrasonic probe (model JY92-2D, Ningbo Xinzhi Company) and kept in an ice bath, and the JY92-2D ultrasonic probe penetrates into the liquid surface of the soybean protein iso...

Embodiment 2

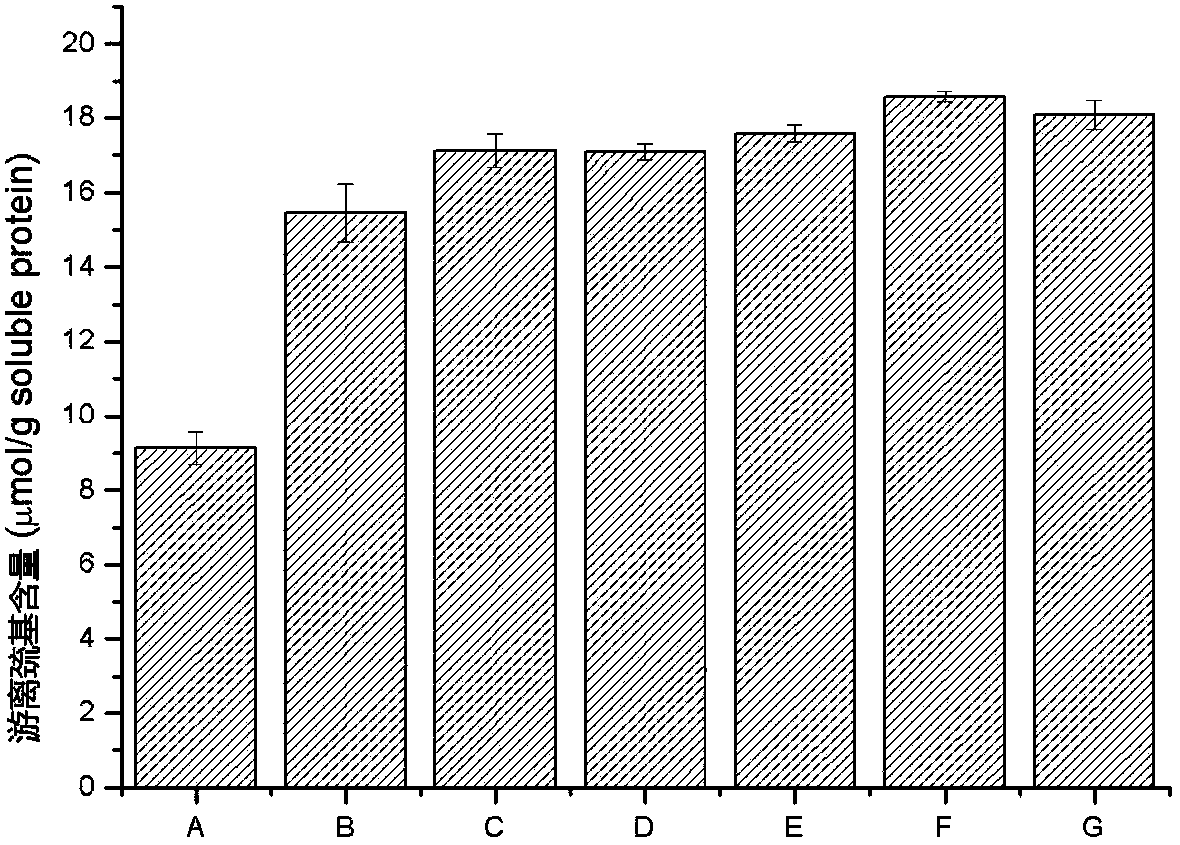

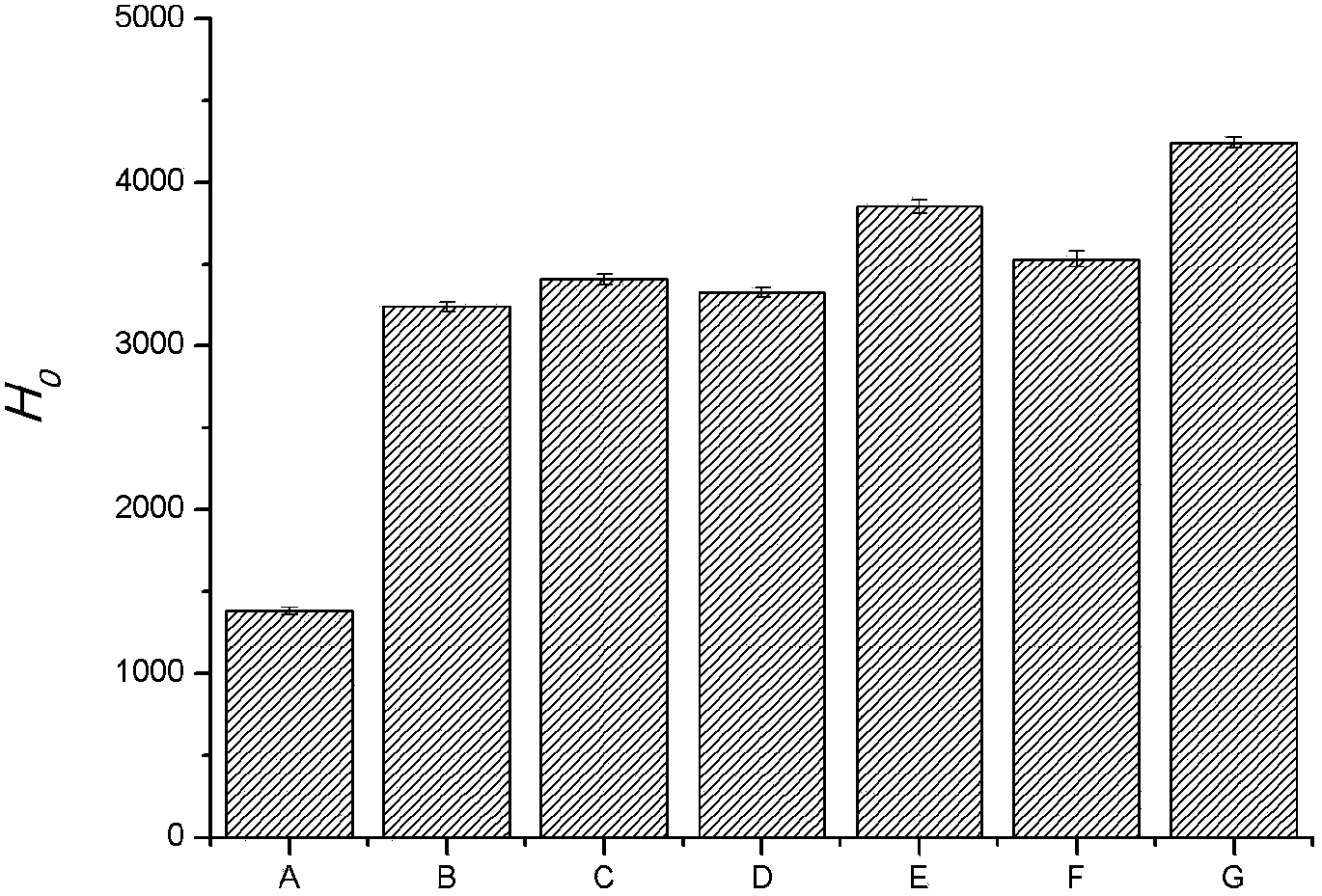

[0036] Example 2: Experiments on the Effects of Different Ultrasonic Powers and Time on the Structure and Basic Properties of Soybean Protein Isolate

[0037] Experiments and instruments: soybean protein isolate was purchased from Shandong Yuwang Company; AR2000 rheometer (TA Instruments, Leatherhead, UK); spectrophotometer; circular dichroism chromatography (Jasco810, Jasco Corp. Tokyo, Japan); pH meter.

[0038] (1) Determination of protein solubility

[0039] According to the method of Example 1, after the soybean protein isolate powder was made into a solution, the soybean protein isolate powder finished product was prepared after being treated respectively for 15 and 30 minutes under 200W, 400W and 600W ultrasonic conditions. Dissolve the lyophilized control sample and finished soybean protein isolate powder (2 mg / mL) in distilled water (pH 8.0) respectively, shake at room temperature for 24 hours to fully dissolve and disperse the protein, and place the stirred protein m...

Embodiment 3

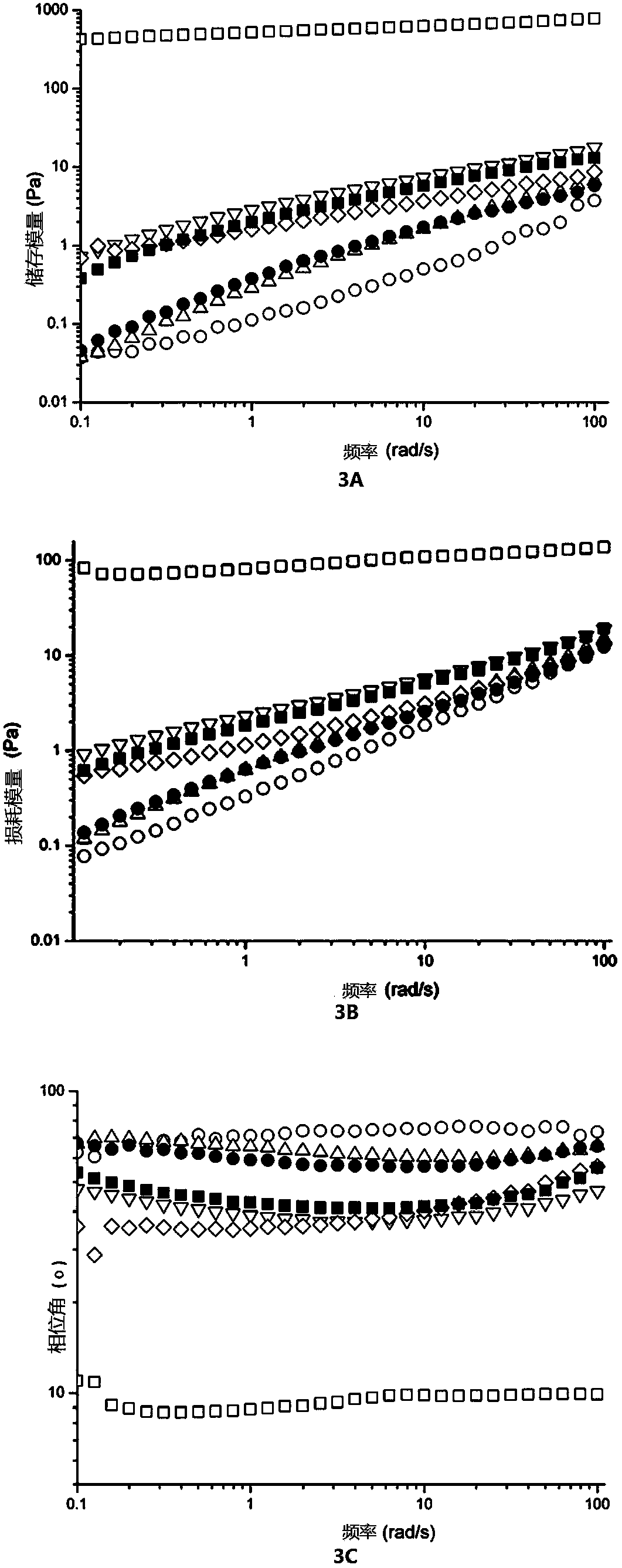

[0060] Embodiment 3: the test of preparing bean curd type gel with lactone as coagulant

[0061] Materials and instruments: Commercially purchased soybean protein isolate (purchased from Shandong Yuwang Company), gluconolactone (GDL), texture analyzer, centrifuge, spectrophotometer, and water bath.

[0062] (1) Preparation of lactone-induced gel

[0063]Referring to the method of Example 1, after the soybean protein isolate powder was made into a solution, it was processed under 400W ultrasonic conditions for 5, 20 and 40 minutes respectively and then freeze-dried to make a soybean protein isolate powder finished product. The freeze-dried finished soybean protein isolate powder was used as a control with untreated commercial soybean protein isolate. The above different samples were dissolved in distilled water at a concentration of 10%, and stirred at room temperature for 2 h. The stirred solution was left standing overnight at 4°C to fully dissolve the protein. After the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com