Method for fast displaying original austenite grains of maraging steel containing Cr

A technology of maraging steel and austenite grains, applied in the field of physical detection, can solve the problems of difficulty in displaying austenite grains, and achieve the effects of short corrosion time, good reproducibility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

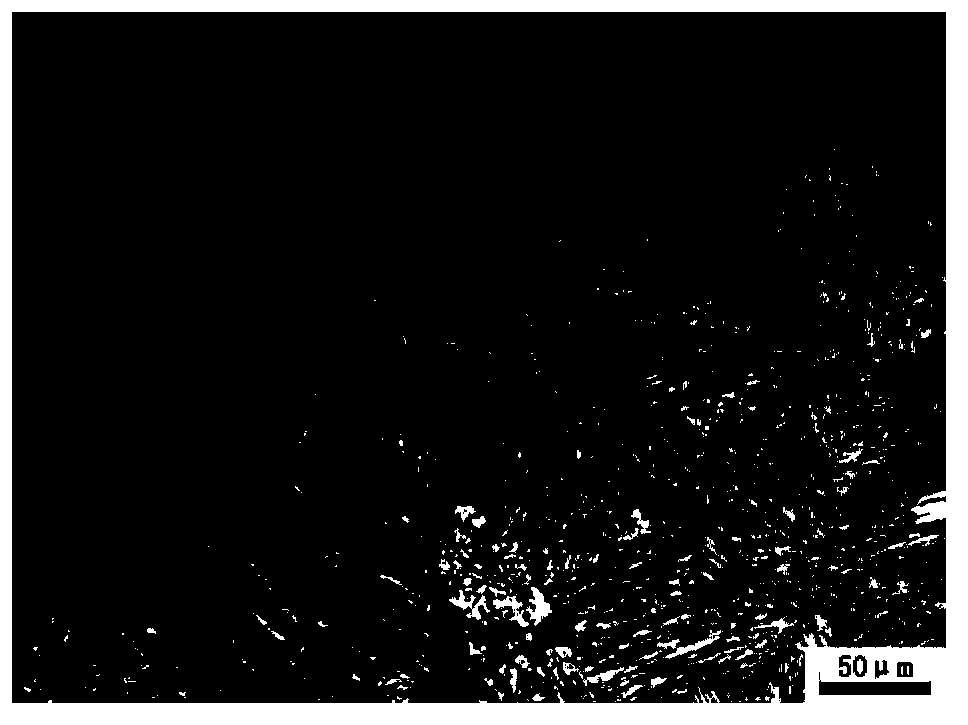

Embodiment 1

[0020] Example 1: Chemical composition (wt%) of sample 1: C: 0.002, Ni: 14.06, Cr: 3.19, Ti: 1.32, Al: 0.16, Si: 0.064, Mn: 0.032, S: 0.002, P: 0.0019 , and the balance is unavoidable inclusions and iron. Grind and polish the sample after solid solution treatment after heat preservation at 510°C for 5 hours and aging; configure the etchant according to the following ratio: 36% hydrochloric acid by mass percentage: 10ml, and 68% nitric acid: 1 ml, distilled water: 10ml. When preparing, first measure 10ml of distilled water and put it in a container, then add hydrochloric acid and nitric acid to the distilled water, and stir with a glass rod. Due to the exothermic reaction, the prepared corrosive agent needs to be allowed to stand for 3 minutes. Put a little absorbent cotton on the bottom of the vessel, then put the polished sample into the solution for corrosion, the etched surface of the sample faces down, the etching time is 20s, take it out when the polished surface of th...

Embodiment 2

[0021] Example 2: Chemical composition (wt%) of sample 2: C: 0.0018, Ni: 12.64, Cr: 8.92, Ti: 1.37, Al: 0.052, Si: 0.016, Mn: 0.010, S: 0.003, P: 0.0024 , and the balance is unavoidable inclusions and iron. Grind and polish the sample after solid solution treatment + cold treatment after heat preservation at 510°C for 5 hours; configure the etchant according to the following ratio: 36% hydrochloric acid by mass percentage: 10ml, 68% nitric acid by mass percentage: 2ml, distilled water: 10ml . When preparing, first measure 10ml of distilled water and put it in a container, then add hydrochloric acid and nitric acid to the distilled water, and stir with a glass rod. Due to the exothermic reaction, the prepared corrosive agent needs to be allowed to stand for 3 minutes. Put a little absorbent cotton on the bottom of the vessel, then put the polished sample into the solution for corrosion, the etched surface of the sample faces down, the etching time is 30s, take it out when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com