Pitching assembly of radar scanner for detecting foreign matters on runways

A foreign object detection and scanner technology, used in supporting machines, mechanical equipment, machines/supports, etc., can solve the problems of limited control volume, limited number of gear series teeth, increased transmission error, low speed requirements, etc. Scanning accuracy and scanning speed, avoidance of gear rotation errors and wear, effects of high precision and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

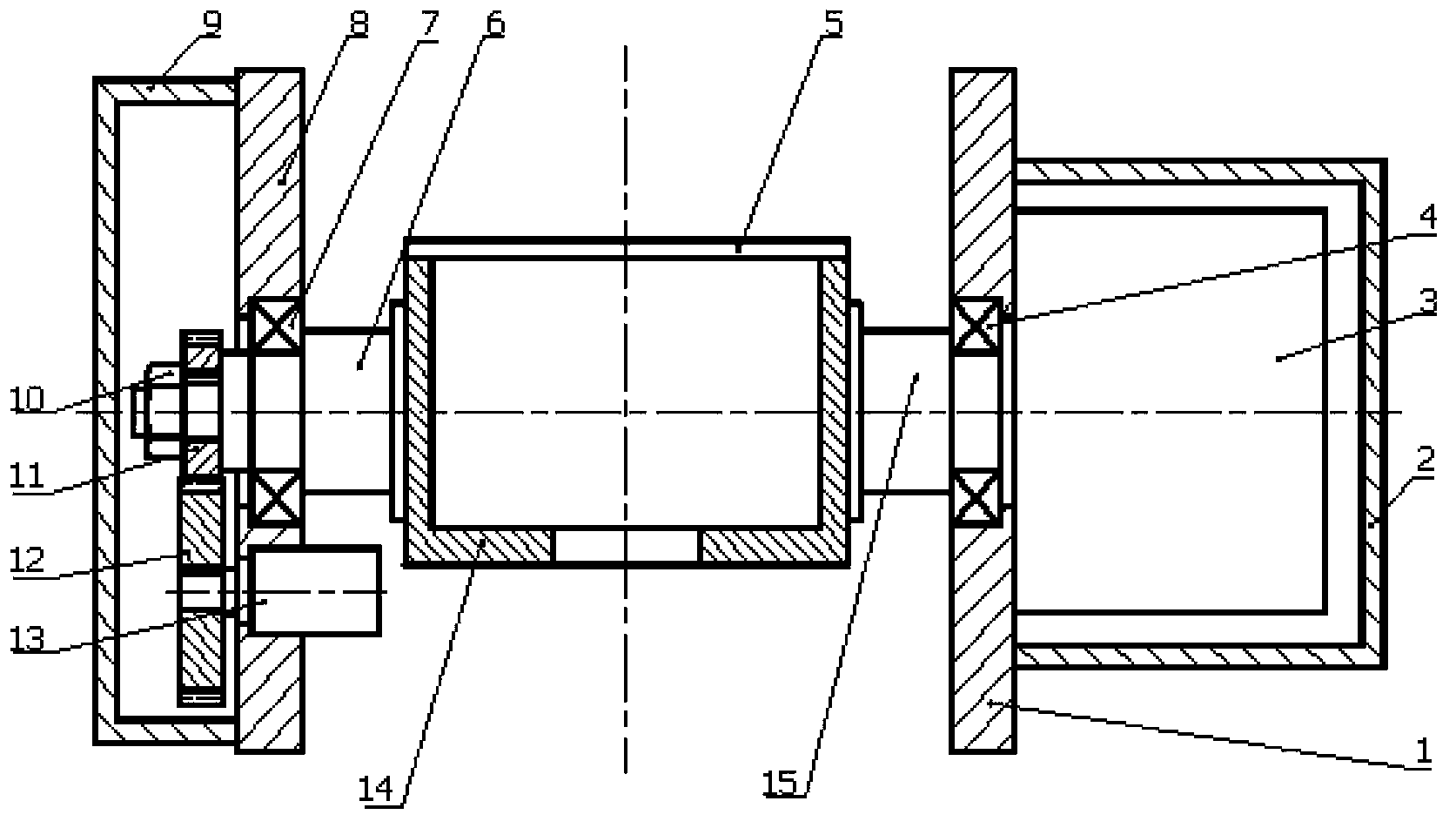

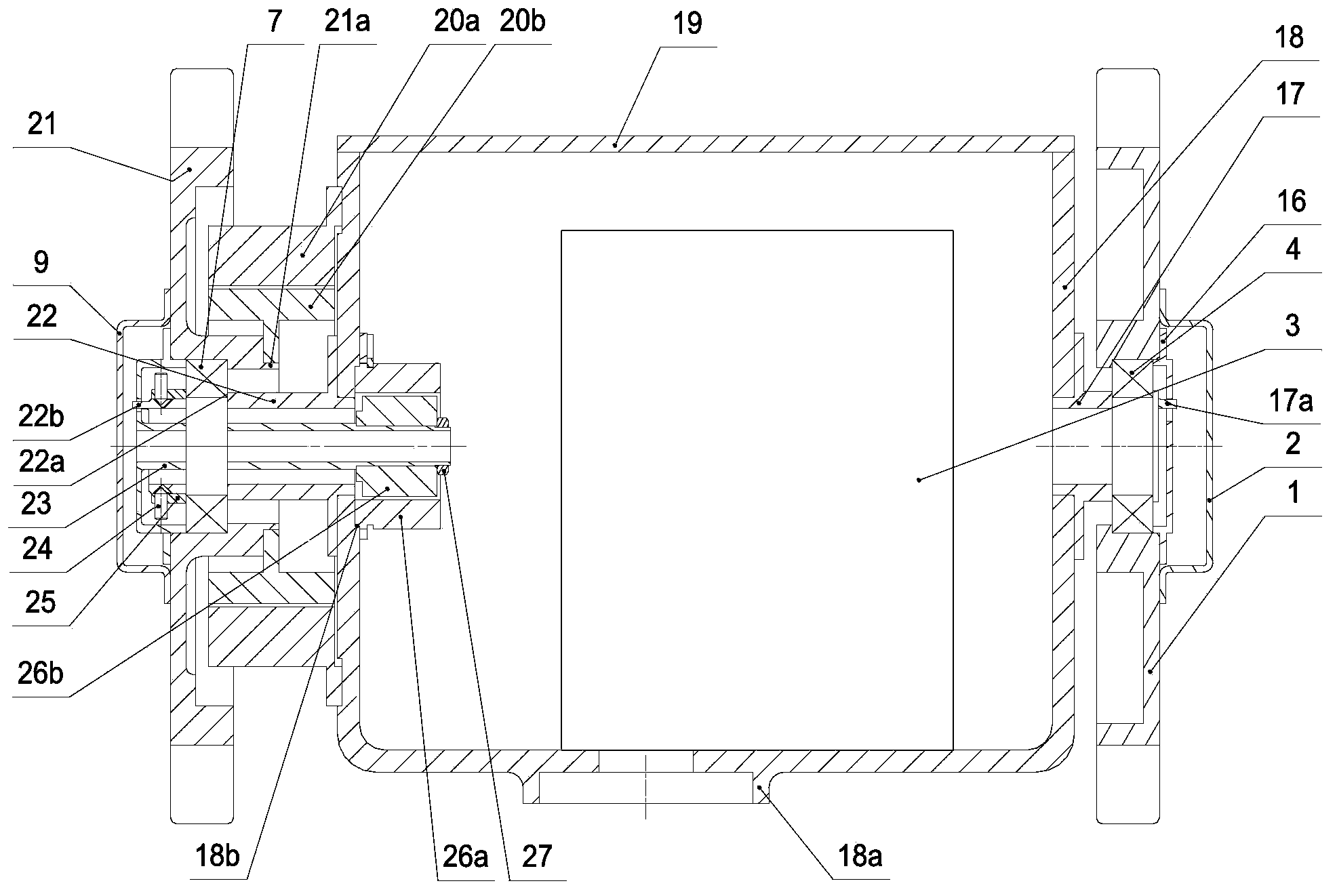

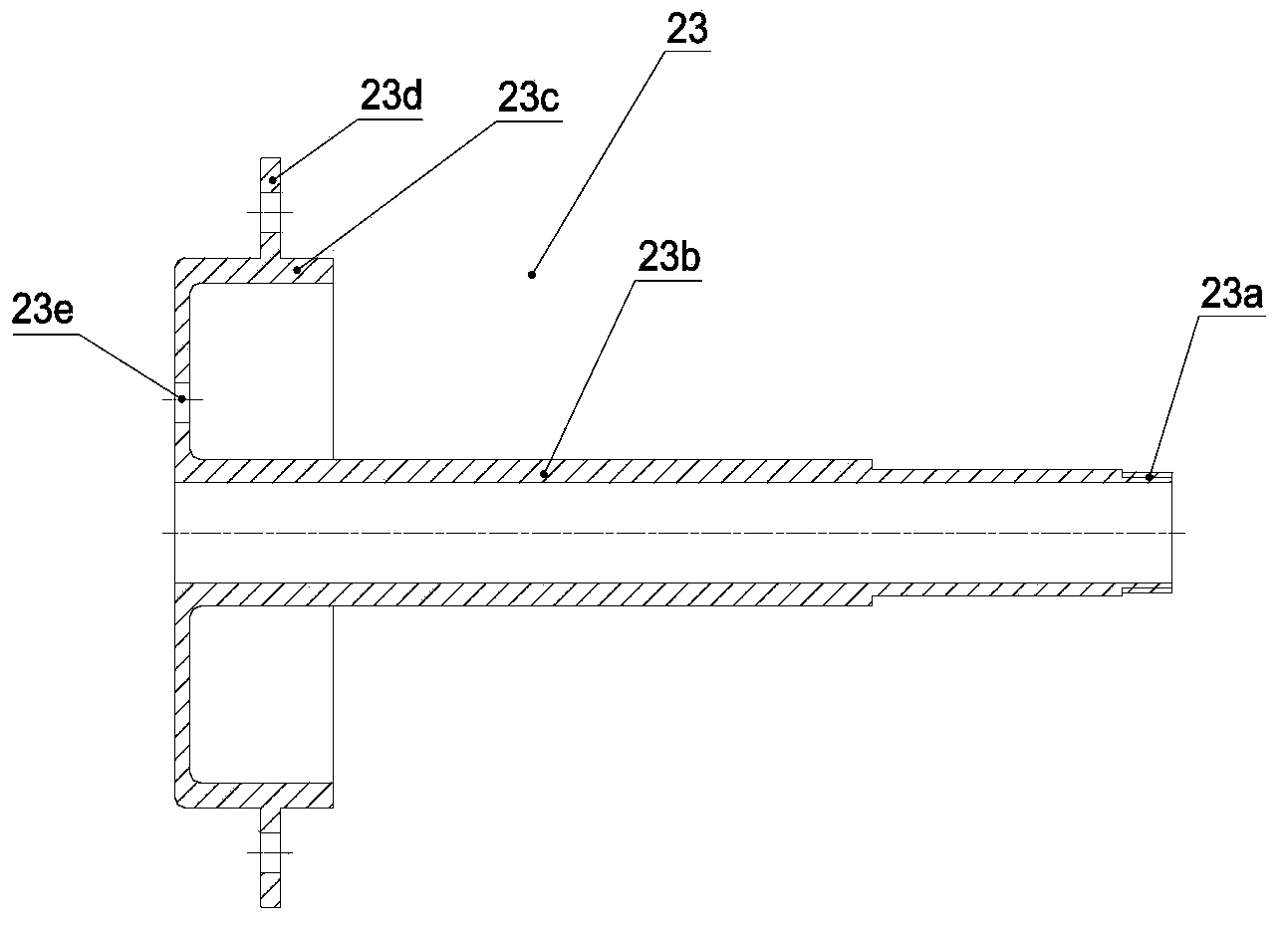

[0023] The present invention will be described in further detail below. see figure 2 , 3 , a pitching part of a runway foreign object detection radar scanner, which is composed of a pitching frame assembly, a left backing board assembly, a right backing board assembly and a servo module; the pitching frame assembly includes a pitching frame and a pitching frame end cover, and the pitching frame is an upper opening The cuboid chassis, the end cover of the pitch frame is fixed on the upper end surface of the pitch frame by screws; the left back board assembly includes the left back board, the left back board cover (9), the left bearing (7) and the left arm, and the left back board is a There is a flat plate with a counterbore in the middle, and the left leaning plate cover (9) is a cup-shaped cover, which is fixed on the middle part of the left side of the left leaning plate by screws, and the left arm is a short shaft with a mounting flange on the right end, and the left arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com