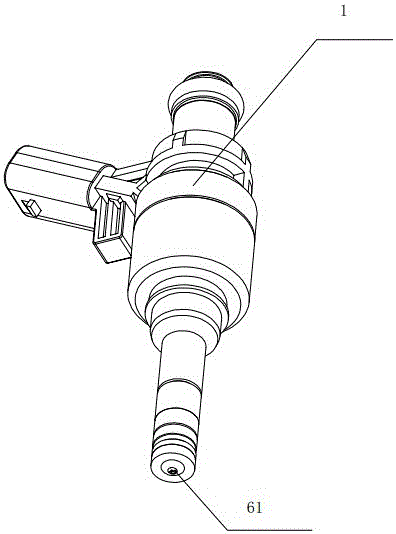

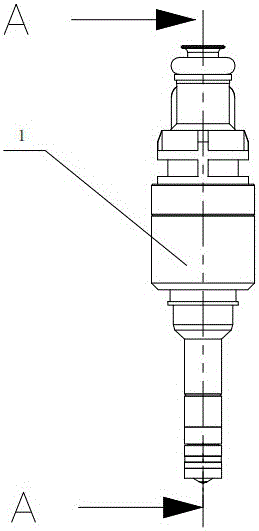

an engine fuel injector

A fuel injector and engine technology, used in engine components, machines/engines, mechanical equipment, etc., can solve problems such as poor fuel injection quality and insufficient fuel injection speed, achieve thorough atomization, shorten response time, and reduce volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

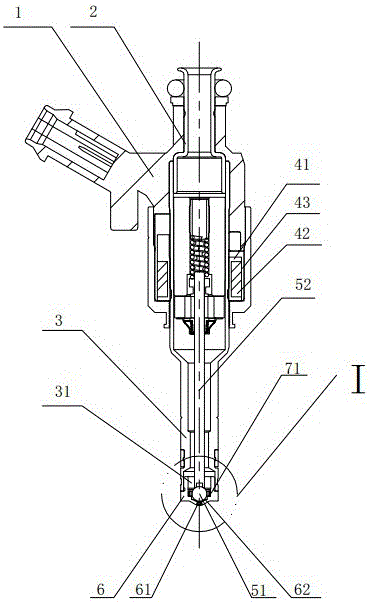

[0030] Embodiment one: by figure 1 combine figure 2 , 3 , 4, 5, 10, 11, 12, and 13, a fuel injector for an engine includes a housing 1, an oil inlet pipe 2 and an oil outlet pipe 3, the oil inlet pipe 2 communicates with the oil outlet pipe 3, and the The casing 1 is provided with a coil assembly 4, the oil outlet cavity 31 of the oil outlet pipe 3 is provided with a valve core assembly 5 and a valve cover 6, and the valve cover 6 is provided with an oil injection hole 61, and the valve core The assembly 5 includes a valve core 51 and a valve stem 52, and the valve cover 6 is provided with an oil separator 7, and the valve core 51 of the valve core assembly 5 passes through the oil separator 7 and is attached to the inner wall of the valve cover 6, An oil injection chamber 62 is formed between the valve core 51 , the oil separator 7 and the valve cover 6 , and the oil separator 7 is provided with a communication groove 71 for communicating the oil outlet chamber 31 with the...

Embodiment 2

[0034]Embodiment 2: The oil inlet pipe in Embodiment 1 is directly connected with the oil outlet pipe. In Embodiment 2, the oil inlet pipe 2 and the oil outlet pipe 3 shown in 6, 7, 8, 9, 10, and 11 can be used by adjusting The sleeve 8 is connected, and the adjustment sleeve 8 is connected with the valve core assembly 5. The valve rod 52 on the valve core assembly 5 is provided with an oil through hole 521 for communicating with the oil outlet chamber 31. The fuel oil passes through the oil inlet pipe 2, the adjustment sleeve 8, The oil through hole 521 on the valve core assembly 5 flows into the oil outlet chamber. In the first embodiment, there is a step inside the valve cover. In the second embodiment, the oil separator is directly placed in the groove of the valve cover, and the valve core is sealed with the conical surface of the valve cover. The injection from the communication groove is injected into the fuel injection chamber, and then injected into the engine to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com