A Method for Determining the Position of the Clamp on the Engine Pipeline

A technology of engine and engine casing, applied in the direction of machine/engine, gas turbine device, mechanical equipment, etc., can solve the problems that affect the assembly quality of the external pipeline of the engine, cannot express the installation position of the clamp, and the assembly position is uncertain, etc., to achieve Improve assembly quality, less impact, and improve the effect of final assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

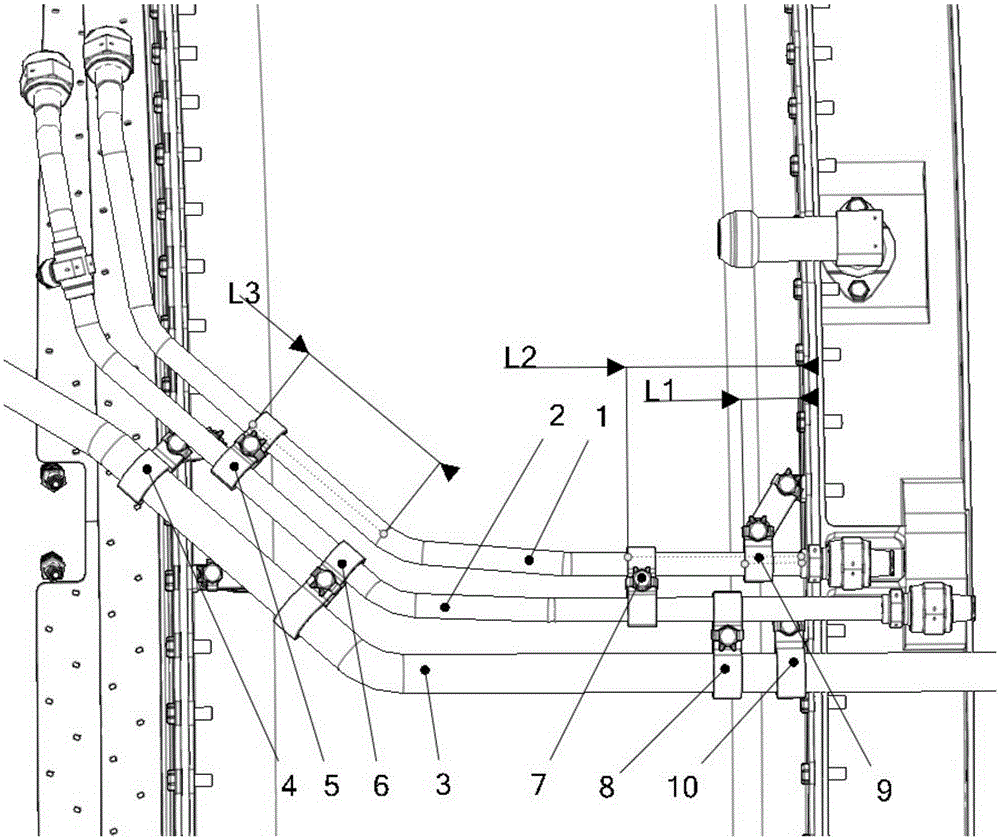

[0016] This embodiment provides a method for determining the position of the clamp on the engine pipeline, which is characterized in that: the first pipeline 1, the second pipeline 2 and the third pipeline 3 pass through the first clamp 4 and the second clamp respectively 5. The third clamp 6, the fourth clamp 7, the fifth clamp 8, the sixth clamp 9 and the seventh clamp 10 are fixed to each other or on the engine casing;

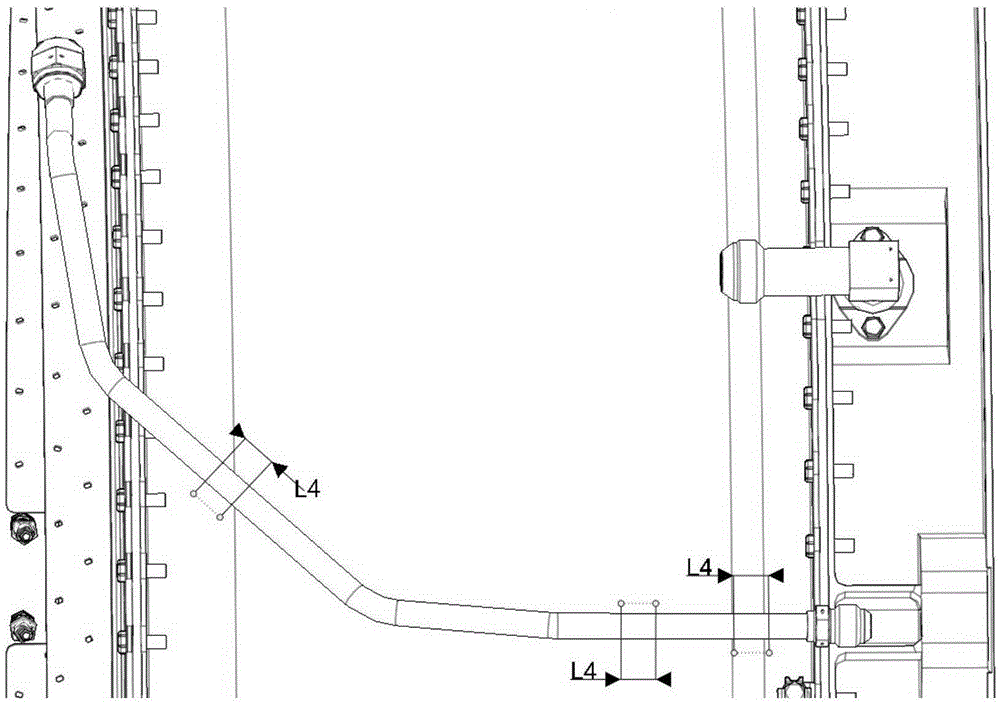

[0017] The position of the clamp on pipeline 1 is determined according to the distances L1 and L2 to the two welds and the distance L3 to the bend tangent on the pipeline; the length L4 of the clamp position is the width of the clamp.

[0018] The position of the clamp is marked by painting, sand blowing and electrolytic marking.

[0019] The width of the electrolytic paper is L4. After dipping in the electrolyte, it is wrapped on the outer wall of the pipeline, and two ring-shaped black marks are printed on the electrodes.

Embodiment 2

[0021] This embodiment provides a method for determining the position of the clamp on the engine pipeline, which is characterized in that: the first pipeline 1, the second pipeline 2 and the third pipeline 3 pass through the first clamp 4 and the second clamp respectively 5. The third clamp 6, the fourth clamp 7, the fifth clamp 8, the sixth clamp 9 and the seventh clamp 10 are fixed to each other or on the engine casing;

[0022] The position of the clamp on pipeline 1 is determined according to the distances L1 and L2 to the two welds and the distance L3 to the bend tangent on the pipeline; the length L4 of the clamp position is the width of the clamp, with a tolerance of 2mm.

[0023] The position of the clamp is marked by painting, sand blowing and electrolytic marking.

[0024] The width of the electrolytic paper is L4. After dipping in the electrolyte, it is wrapped on the outer wall of the pipeline, and two ring-shaped black marks are printed on the electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com