Rotor assembly and consequent pole motor

A technology of alternating poles and components, applied in the direction of electric components, magnetic circuit rotating parts, synchronous machines, etc., can solve the problems of unable to adjust the magnetic force lines, large motor torque fluctuations, and disordered distribution of permanent magnet poles, so as to reduce the rotation speed. Moment fluctuation, improved reliability, and reduced magnetic saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

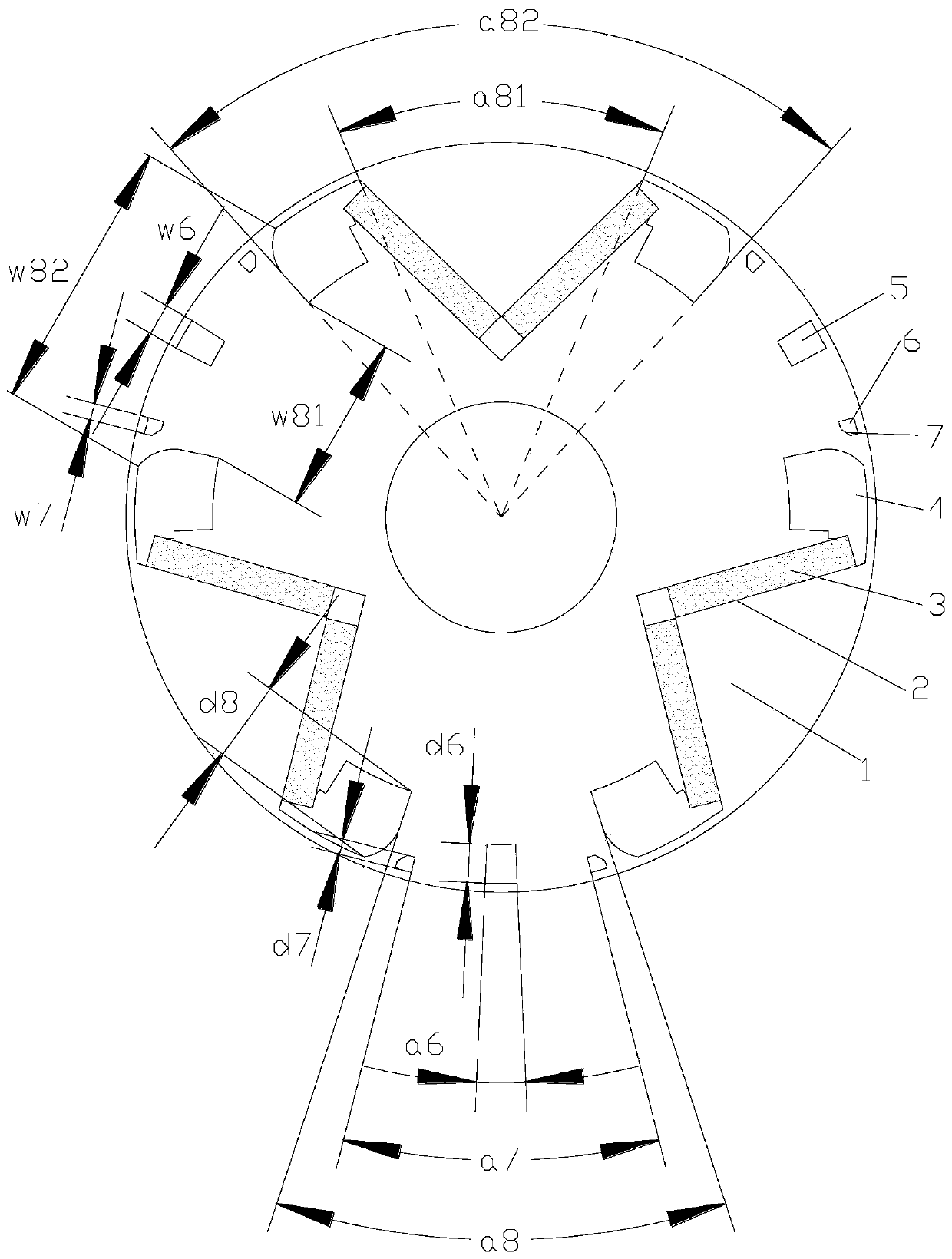

[0033] see in conjunction Figure 1 to Figure 7 As shown, according to the embodiment of the present application, the rotor assembly includes a rotor core 1, the rotor core 1 includes permanent magnet poles and alternate poles arranged alternately along the circumferential direction, the permanent magnet poles include installation slots 2, and permanent magnet poles are installed in the installation slots 2. For the magnet 3 , the circumferential ends of the mounting groove 2 are provided with first air grooves 4 extending away from the centerline of the permanent magnet poles, and the radially outer peripheral side of the mounting groove 2 is not provided with air grooves.

[0034] The rotor assembly of the present application only arranges the air slots at the alternate poles, and does not set the air slots on the radially outer peripheral side of the installation slot 2 where the permanent magnets 3 are installed, so that the adverse effects of the air slots on the structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com