Water pump

A technology for water pumps and pump bodies, which is applied in the direction of pumps, pump components, variable-capacity pump components, etc., and can solve problems such as backflow and dripping, and achieve the effect of preventing dripping or backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

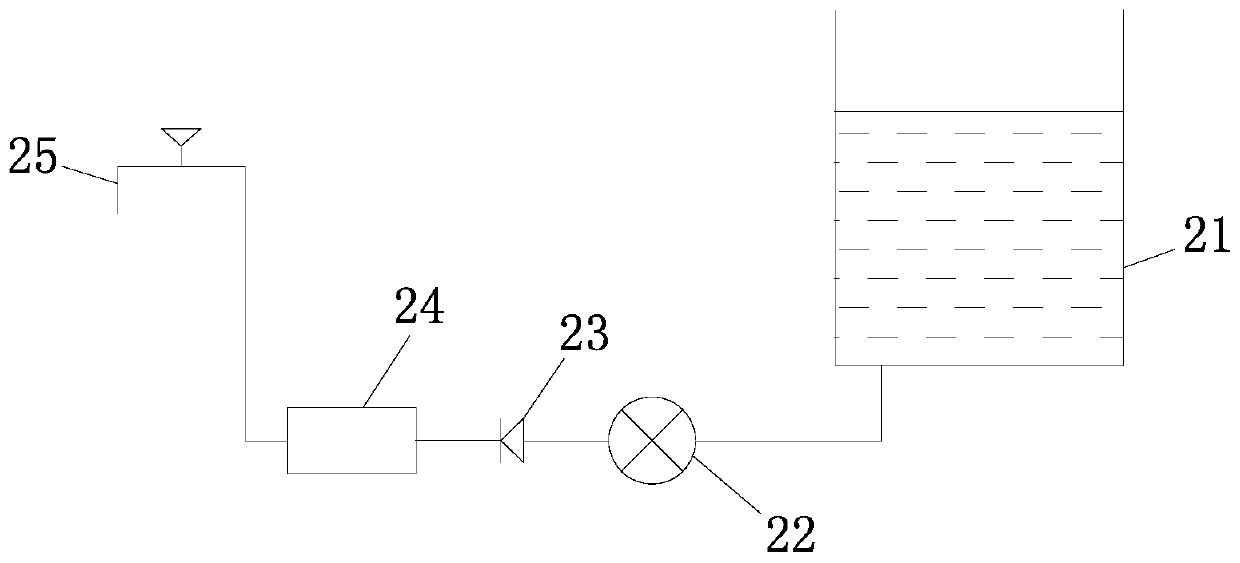

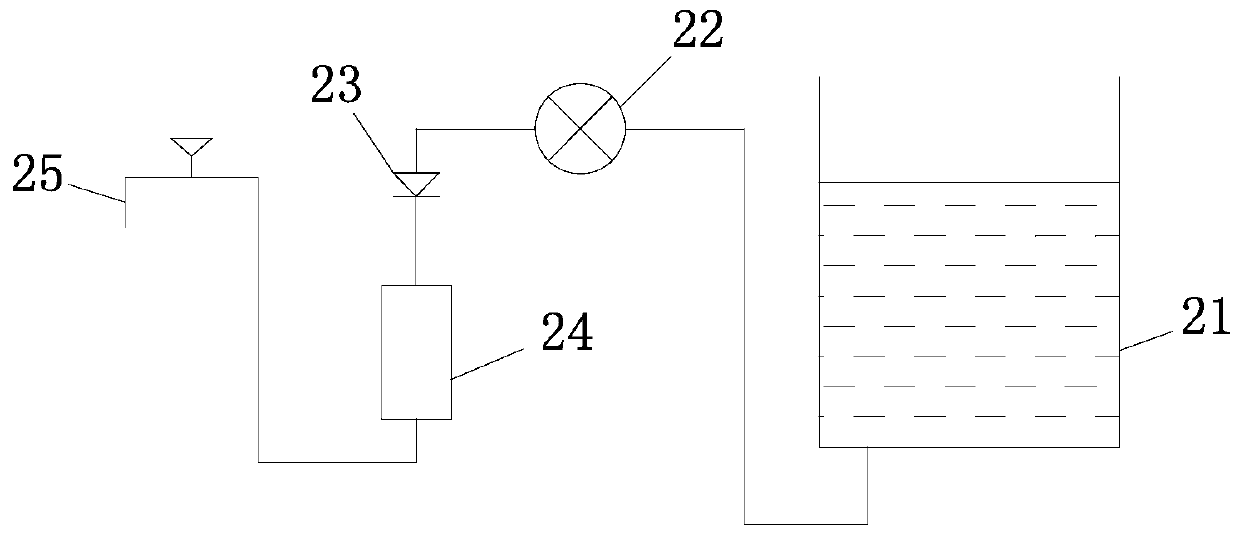

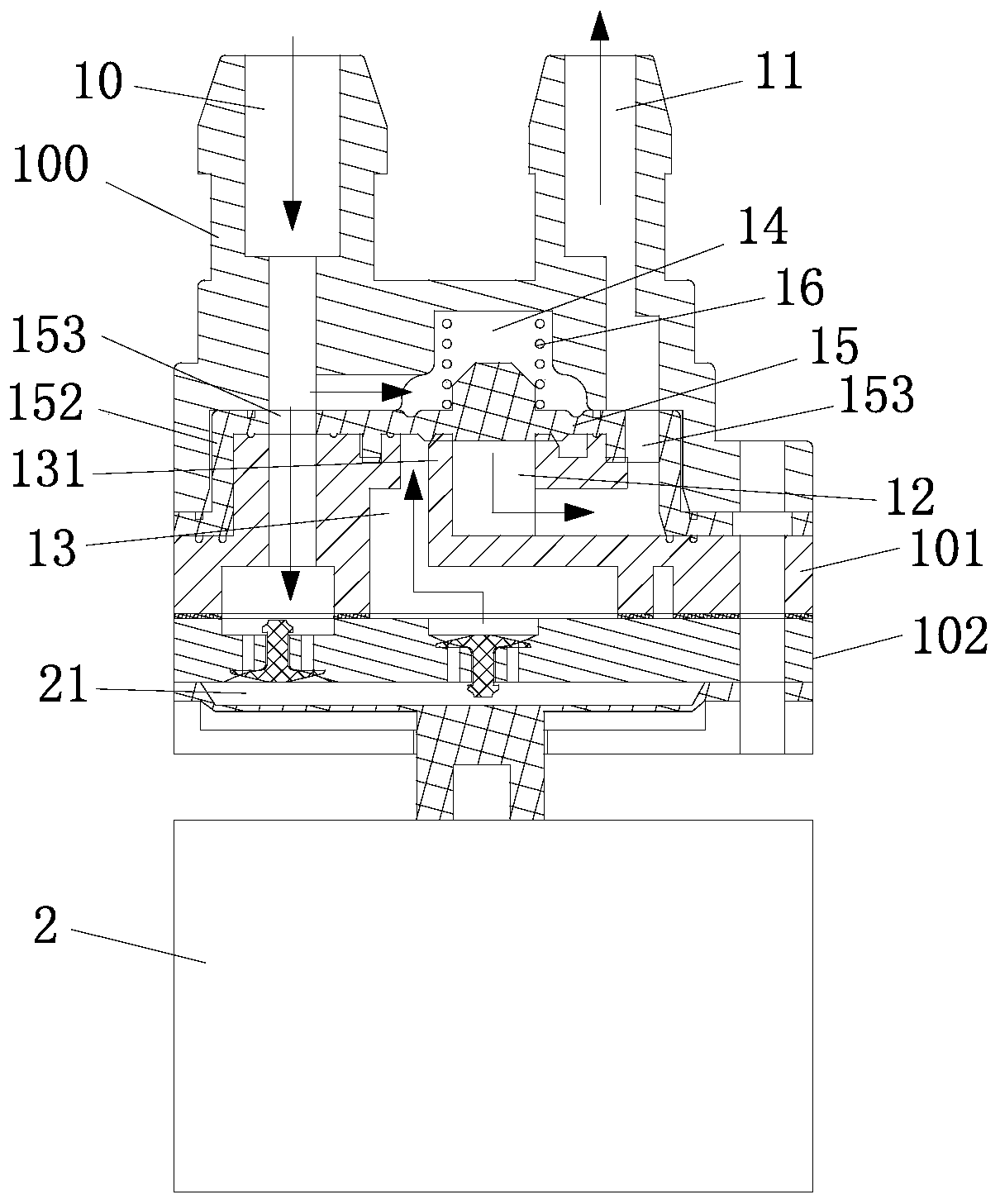

[0022] see image 3 , the water pump comprises an upper pump body 100, a lower pump body 102 and a drive motor 2, the upper pump body 100 is provided with a water inlet 10 and a water outlet 11 with the same water flow direction as the axis direction of the drive motor 2, and the lower pump body 102 A pressurized water chamber 21 is provided, and the drive motor 2 is driven and connected to the pressurized water chamber 21. A water stop assembly is provided between the upper pump body 100 and the lower pump body 102. The water stop assembly includes a water outlet chamber 12, a high pressure chamber 13, the water channel plate 101, the upper pump body 100 and the sealing gasket 15 that constitute the balance chamber 14, the coaxial ring of the high pressure chamber 13 is set outside the water outlet chamber 12, and the bottom surface of the sealing gasket 15 is provided with an elastic cover connected to the high pressure chamber 13 and the sealing water port 131 formed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com