Tunnel lining structure and construction method

A construction method and lining technology, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of hidden safety hazards, low labor cost, large deformation, etc., and achieve a wide range of applications, small impact on construction period, and improved bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

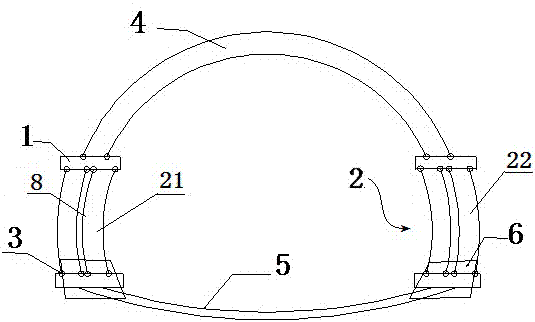

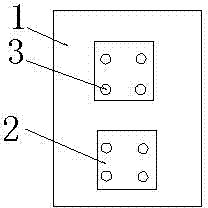

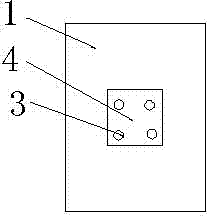

[0045] A tunnel lining structure and construction technology, such as Figure 1-3 As shown, the geological and topographical conditions of the exit section of the tunnel are very poor. On the steep slope section, this section belongs to shallow buried, unbalanced pressure, gully catchment area. Excavate on both sides of the tunnel near the exit section, hang nets separately, assemble and connect double-layer arches, and spray concrete after installing anchor rods.

[0046] The specific operation is as follows:

[0047] (1) Carry out the excavation footage (50cm-60cm) of the hole body at the predetermined position.

[0048] (2) Fix the pre-bound steel mesh on the surrounding rock, using φ8 steel mesh (spacing 20cm×20cm arch wall);

[0049] (3) Assemble and install the steel arch. The specific method is: assemble the required I-beams into inner and outer steel arches, connect the I-beams with bolts, and connect them with the upper and lower steel plates with bolts, and weld ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com