Three-soft-coal-layer reciprocating-type coal-pillar-free fully-mechanized mining method

A three-soft coal seam, reciprocating technology, applied in ground mining, mining equipment, earth-moving drilling and other directions, can solve the problems of poor roadway safety, waste of resources, complicated support, etc., to improve resource recovery rate and reduce coal pillar retention. design, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

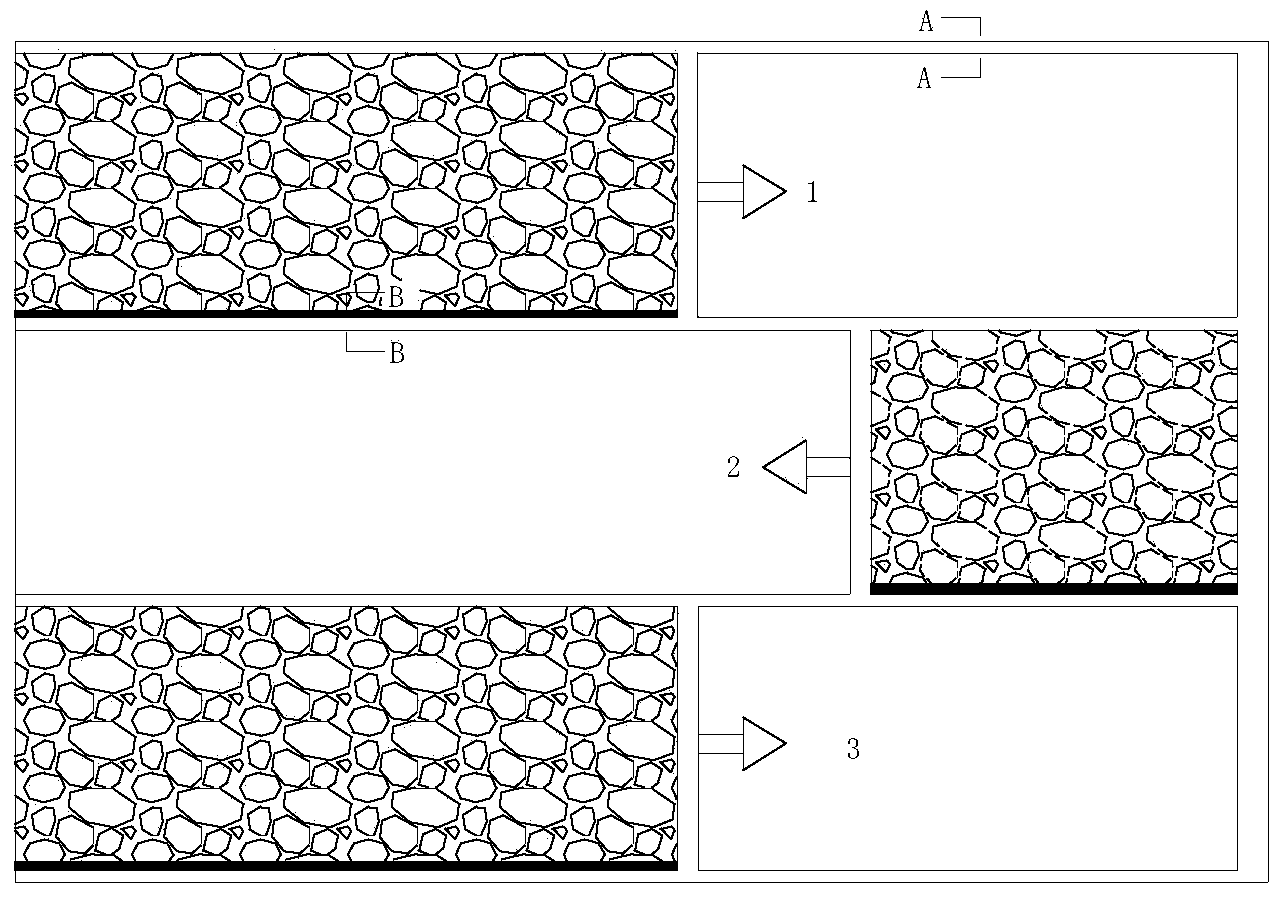

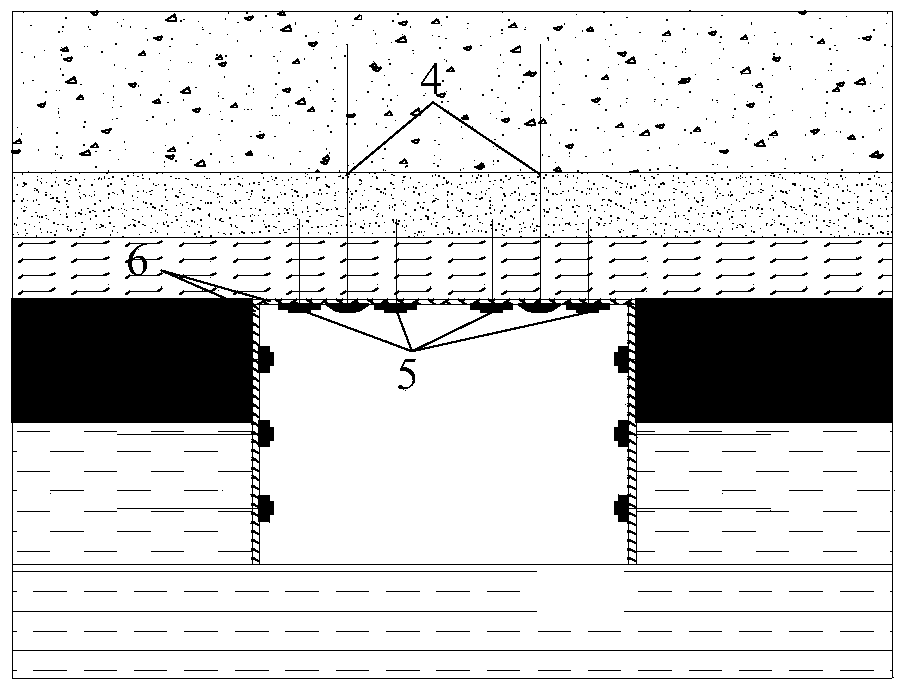

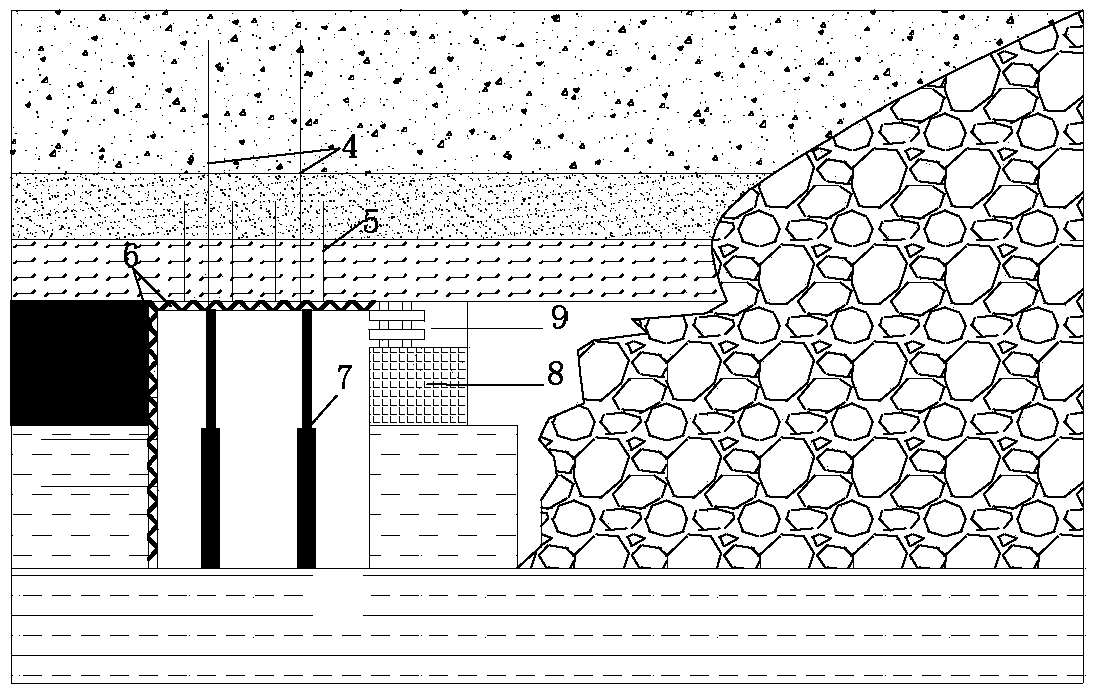

[0016] See attached figure 1 , which describes the underground roadway layout in the three-soft coal seam reciprocating coal pillar-free fully mechanized mining method of the present invention. Firstly, a plurality of parallel and adjacent working faces are set. In this embodiment, there are three working faces, which are respectively working face one, working face two and working face three, and roadways are set between every two adjacent working faces. Each working face is mined sequentially, and two adjacent working faces are mined alternately by advancing coal mining method and retreat coal mining method. If the retreating coal mining method is used for mining at the first mining face (that is, working face 1 in this embodiment), the forward mining method is adopted for the adjacent next working face; if the forward mining method is adopted for mining at the first mining face The coal mining method is used for mining, and the adjacent next working face is mined by retreat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com