A method for comprehensive recovery and utilization of gold mud wet process tail gas

A wet process and tail gas technology, which is applied in the field of comprehensive recovery and utilization of tail gas of gold mud wet process, can solve the problems of waste, alkaline circulating waste liquid not being recycled, and not being further recycled, etc., and achieve the effect of eliminating pollution hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

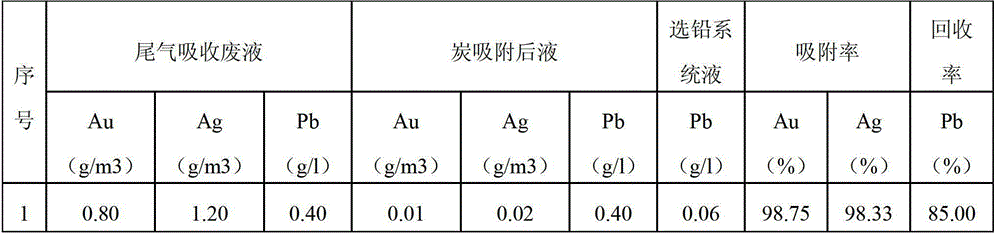

Embodiment 1

[0019] A method for comprehensive recovery and utilization of gold mud wet process tail gas of the present invention comprises the following steps:

[0020] 1) Gold slime preparation process: Gold and silver concentrates are directly cyanided to extract gold and zinc powder replacement process to obtain gold mud and cyanided gold tailings, of which gold mud contains 31.50% gold, 12.50% silver, 13.50% copper, 6.50% lead, 26.50% zinc;

[0021] 2) Gold mud acid leaching process: pickling the gold mud obtained in step 1) with dilute nitric acid with a mass fraction of 20%, the mass ratio of dilute nitric acid to gold mud is 5:1 during pickling, and the temperature of the acid leaching is 80°C , the time of the acid leaching is 6 hours; the tail gas produced (the base metal in the gold mud in the acid leaching operation process reacts with nitric acid to produce nitrogen oxide gas, due to the violent reaction, accompanied by the generation of bubbles, nitrogen oxides and bubbles bu...

Embodiment 2

[0028] A method for comprehensive recovery and utilization of gold mud wet process tail gas of the present invention comprises the following steps:

[0029] 1) Gold mud preparation process: Gold and silver concentrates are directly extracted by cyanide and zinc powder replacement process to obtain gold mud and cyanidation gold tailings, of which gold mud contains 50% gold, 15% silver, 15% copper, 10% lead, 10% zinc;

[0030] 2) Gold mud acid leaching process: pickling the gold mud obtained in step 1) with dilute nitric acid with a mass fraction of 10%, the mass ratio of dilute nitric acid to gold mud is 4:1 during pickling, and the temperature of the acid leaching is 60°C , the time of the acid leaching is 5 hours; the tail gas produced (the base metal in the gold mud in the acid leaching operation process reacts with nitric acid to produce nitrogen oxide gas, due to the violent reaction, accompanied by the generation of bubbles, nitrogen oxides and bubbles bursting and splash...

Embodiment 3

[0037] A method for comprehensive recovery and utilization of gold mud wet process tail gas of the present invention comprises the following steps:

[0038] 1) Gold mud preparation process: gold and silver concentrates are directly cyanided to extract gold and zinc powder replacement process to obtain gold mud and cyanided gold tailings, of which gold mud contains 10% gold, 50% silver, 5% copper, 5% lead, 30% zinc;

[0039] 2) Gold mud acid leaching process: pickling the gold mud obtained in step 1) with dilute nitric acid with a mass fraction of 30%, the mass ratio of dilute nitric acid to gold mud is 3:1 during pickling, and the temperature of the acid leaching is 70°C , the time of the acid leaching is 4 hours; the tail gas produced (the base metal in the gold mud in the acid leaching operation process reacts with nitric acid to produce nitrogen oxide gas, due to the violent reaction, accompanied by the generation of bubbles, nitrogen oxides and bubbles bursting and splashi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com