Waterborne epoxy zinc-rich primer

A water-based epoxy zinc-rich and primer technology, applied in the field of coatings, can solve the problems of unhealthy on-site personnel, affect construction efficiency, pollute the environment, etc., and achieve the effects of high mechanical strength of the paint film, improved construction efficiency, and excellent anti-corrosion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

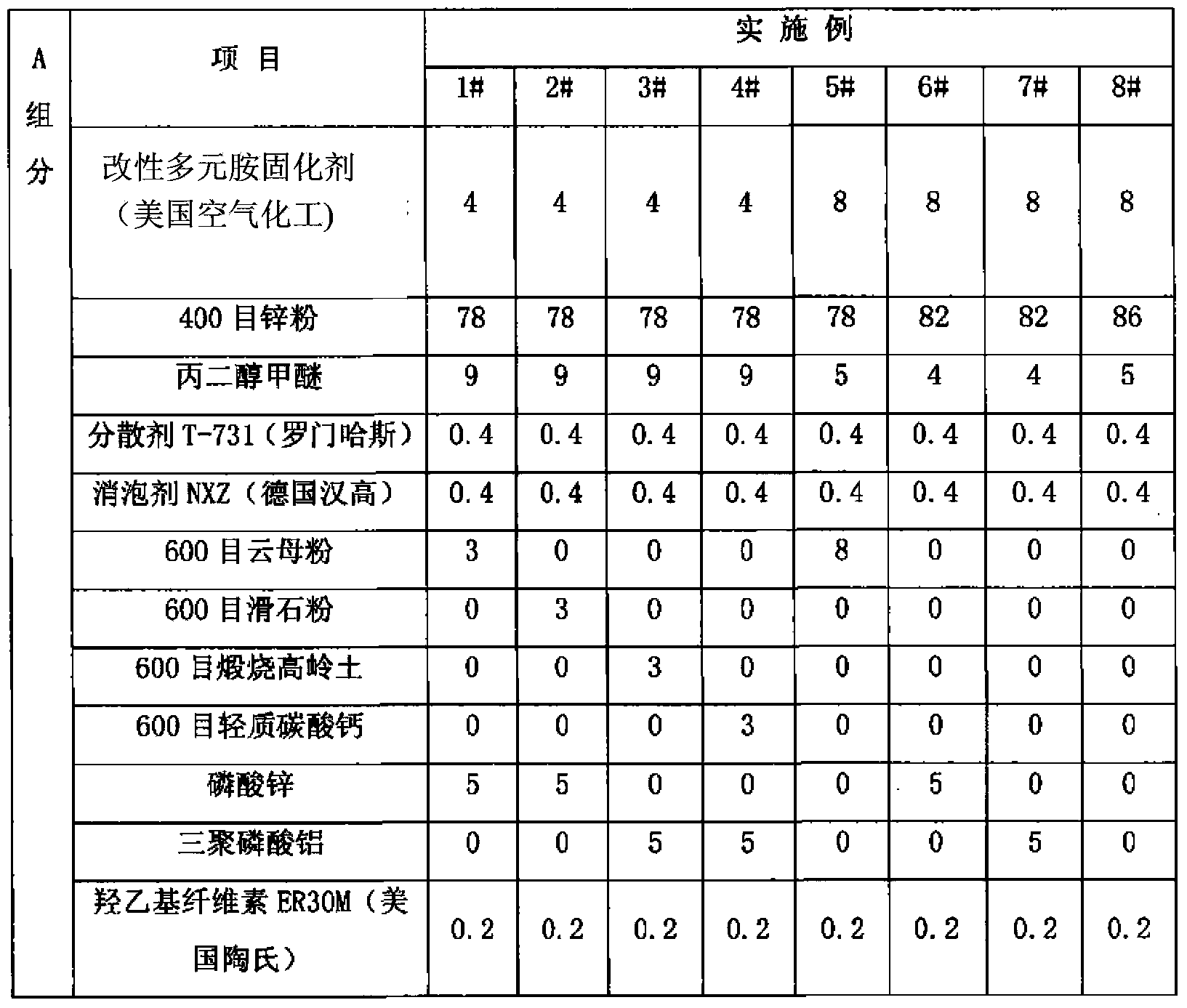

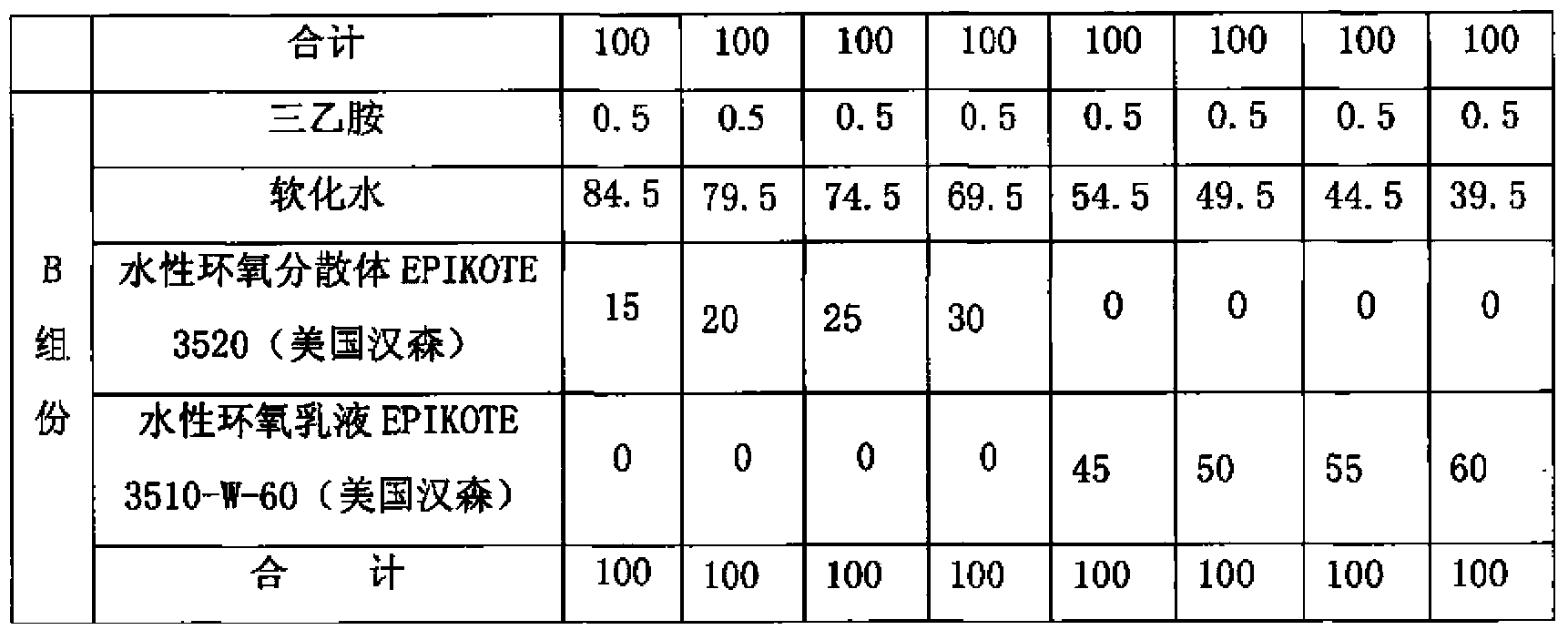

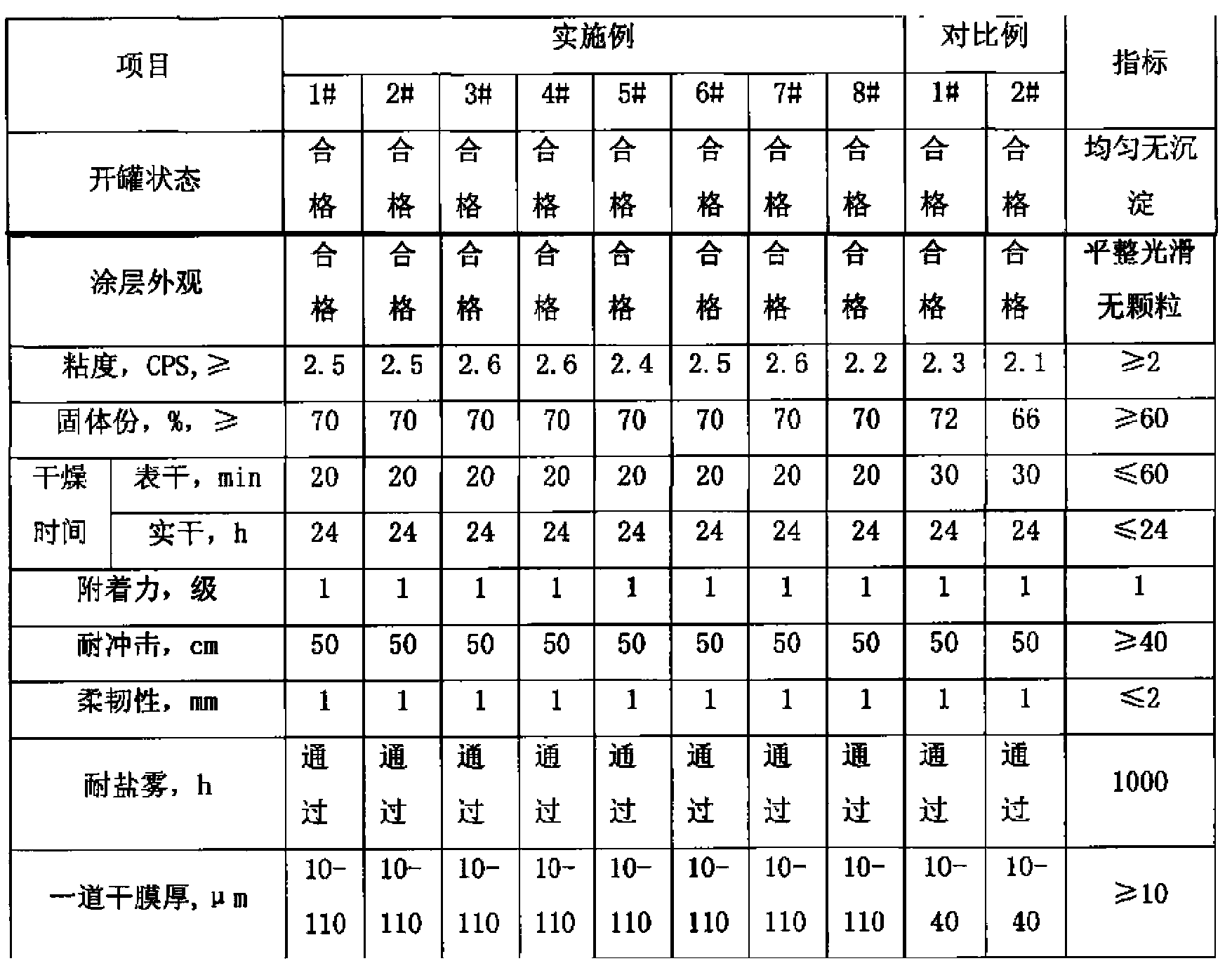

[0024] Table 1 is an example of the present invention, wherein the content of each component is in mass percentage, but the present invention is not limited to the following examples.

[0025] Table 1

[0026]

[0027]

[0028] In Table 1, the above-mentioned modified polyamine curing agent is the water-based modified fatty amine (trialkyl tertiary amine) of American Air Chemicals

[0029] ANCAMN2459 and water-based polyamide ANCAMID2634 are mixed according to the weight ratio of 8:1-10:1; the anti-settling thixotropic agent is Degussa nano-scale fumed silica A200; propylene glycol methyl ether can be replaced by acetone or Ethylene glycol butyl ether; polyacrylic acid sodium salt dispersant can be replaced by other alkenyl monomers (styrene, diisobutylene) and unsaturated carboxylic acid (acrylic acid, methacrylic acid, maleic acid) copolymerization Sodium, ammonium, amine salts of substances, such as Henkel's 5040 dispersant; 600 mesh talcum powder, 600 mesh mica powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com