Machining method of valve seat of relief valve

A technology of overflow valve seat and processing method, which is applied in the field of overflow valve seat processing, can solve problems such as unstable working pressure, affecting the performance of the whole machine, and overflow valve leakage, so as to improve production efficiency and reduce production cost , Improve the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention is a method for processing a valve seat of an overflow valve, which specifically includes the following steps:

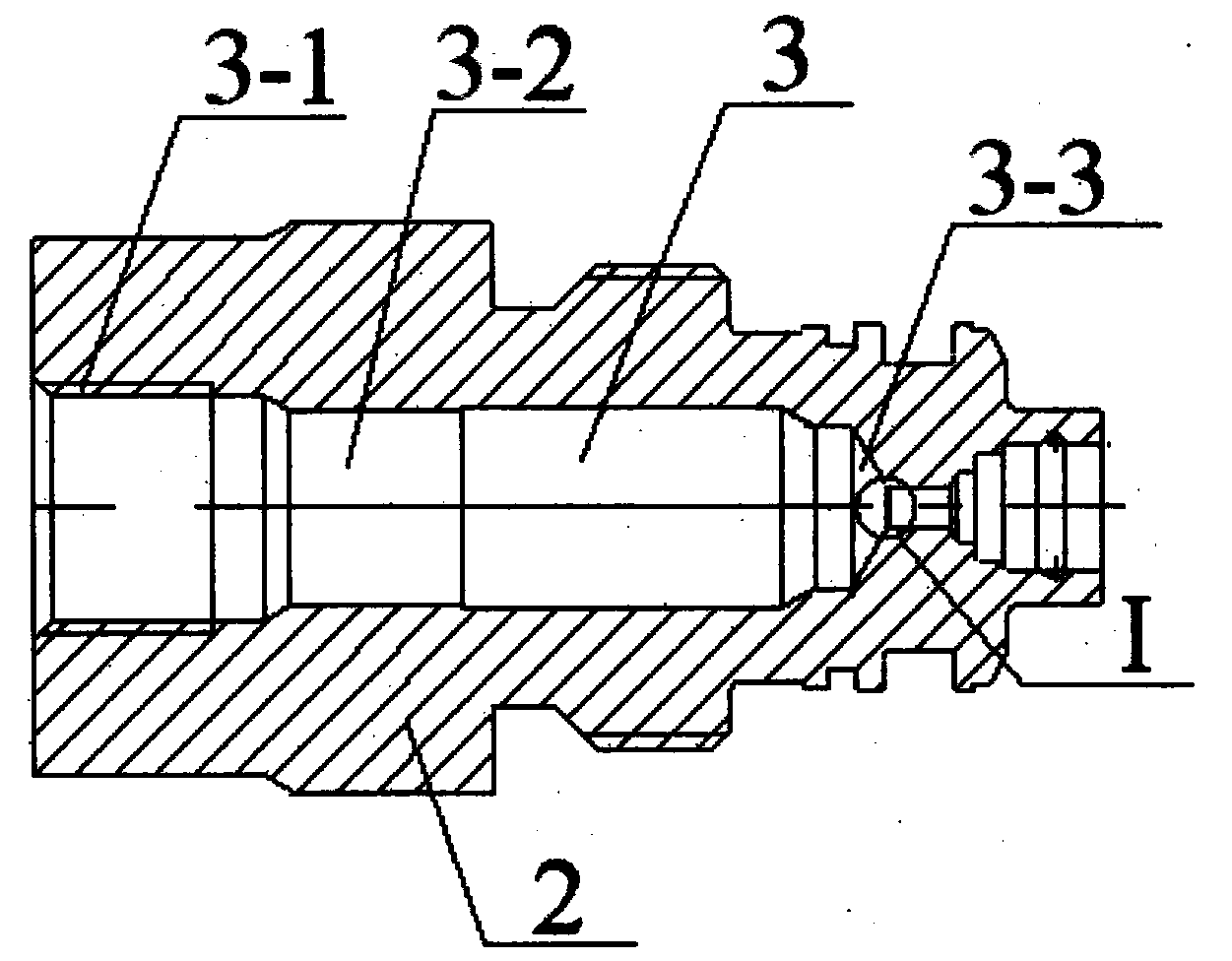

[0026] Step 1: If figure 1 Shown is a structural schematic diagram of the relief valve seat. The valve seat 1 of the overflow valve is turned with a CNC lathe. According to the requirements of the drawing, a rough hole 3 is first drilled on the valve seat 1 of the overflow valve with a φ9 drill bit, and the drilling depth is 45.8mm. The rotating speed of the drill bit is 1500r / min, the feed speed of the drilling bit is 140mm / min, and another φ12.5 tapping drill bit is used to process the threaded bottom hole 3-1 at the bottom of the rough hole 3, and the rotating speed of the tapping bit is is 1000r / min, the feed speed of the tapping drill is 120mm / min, and an enlarged hole 3-2 is formed by a boring tool in the middle section of the rough hole 3, and the enlarged hole 3-2 is bored to φ10.8. The depth is 44mm, the rotating speed of the boring t...

Embodiment 2

[0033] The invention relates to a method for processing a valve seat of an overflow valve. The rotating speed of the drilling drill is 1800r / min, the feeding speed of the drilling drill is 160mm / min, the rotating speed of the tapping drill is 1200r / min, and the tapping drill The feeding speed of the boring tool is 140mm / min, the rotating speed of the boring tool is 1800r / min, and the feeding speed of the boring tool is 160mm / min. The roughness of the tapered hole 3-3 is Ra1.6. Wherein, the rotating speed of the milling cutter is 3000n / min, and the feed speed of the milling cutter is 160mm / min. When using an internal and external cylindrical grinder to grind the enlarged hole 3-2, the rotating speed is 26000n / min, and the feed rate is 300mm / min.

[0034] The coaxiality between the column rod 1-1 in the middle of the self-made grinding tool 2 and the top taper surface 1-2 is 0.005, and the roundness of the taper hole thus processed is 0.008mm. The roughness of the small frustu...

Embodiment 3

[0037]The invention relates to a method for processing a valve seat of an overflow valve. The rotating speed of the drilling drill is 1650r / min, the feeding speed of the drilling drill is 150mm / min, the rotating speed of the tapping drill is 1100r / min, and the tapping drill The feeding speed of the boring tool is 130mm / min, the rotating speed of the boring tool is 1650r / min, and the feeding speed of the boring tool is 150mm / min. The roughness of the tapered hole 3-3 is Ra2.4. Wherein, the rotational speed of the milling cutter is 2800n / min, and the feed speed of the milling cutter is 140mm / min. When using an internal and external cylindrical grinder to grind the enlarged hole 3-2, the rotating speed is 23000n / min, and the feed speed is 250mm / min.

[0038] The coaxiality between the column rod 1-1 in the middle of the self-made grinding tool 2 and the top taper surface 1-2 is 0.004, and the roundness of the taper hole thus processed is 0.006mm. The roughness of the small frus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com