Drawing punch

A punch and end face technology, used in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as tearing of metal parts and increase production costs, and achieve the effects of avoiding damage, reducing production costs, and alleviating impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below by embodiment.

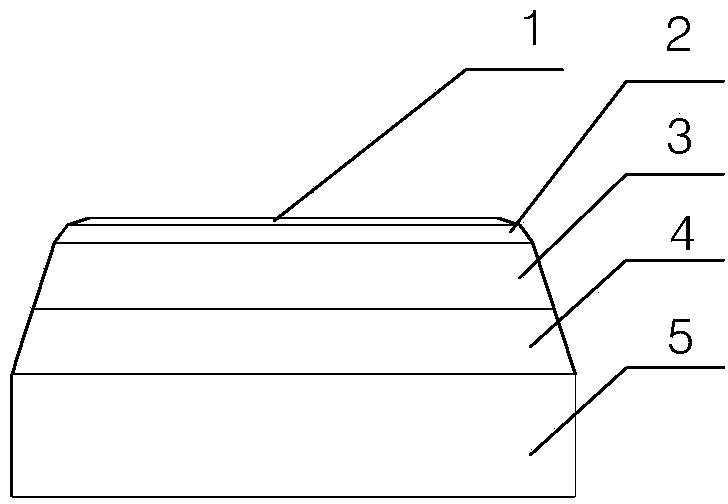

[0010] attached by figure 1 It can be seen that the present invention includes a punch base 5 and a punch end face 1, a transition stretching surface is provided between the punch base 5 and the punch end face 1, and the excessive stretching surface is formed by the third stretching Surface 4, the second stretching surface 3, and the first stretching surface 2 are formed, and indented and transitioned inwardly, wherein the indentation angle between the third stretching surface 4 and the vertical surface is 10-15°, and the second stretching surface The retraction angle between the stretching surface 3 and the vertical surface is 15-20°, and the retraction angle between the first stretching surface 2 and the vertical surface is 20-30°.

[0011] Due to the gradual transition of the stretching surface, when stretching the metal part, the direct impact of the punch on the metal part can be relieved, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com