A plastic film grass and wood separator

A technology of plastic film and separator, which is applied in the direction of solid separation, plastic recycling, and separation of solid from solid with air flow, etc. It can solve the problems of uncontinuous production, no separation machine, difficult film separation, etc., so as to facilitate the advancement , Improve efficiency, improve the effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples. The present invention takes the agricultural film as the separation object, and of course, other films can also be separated.

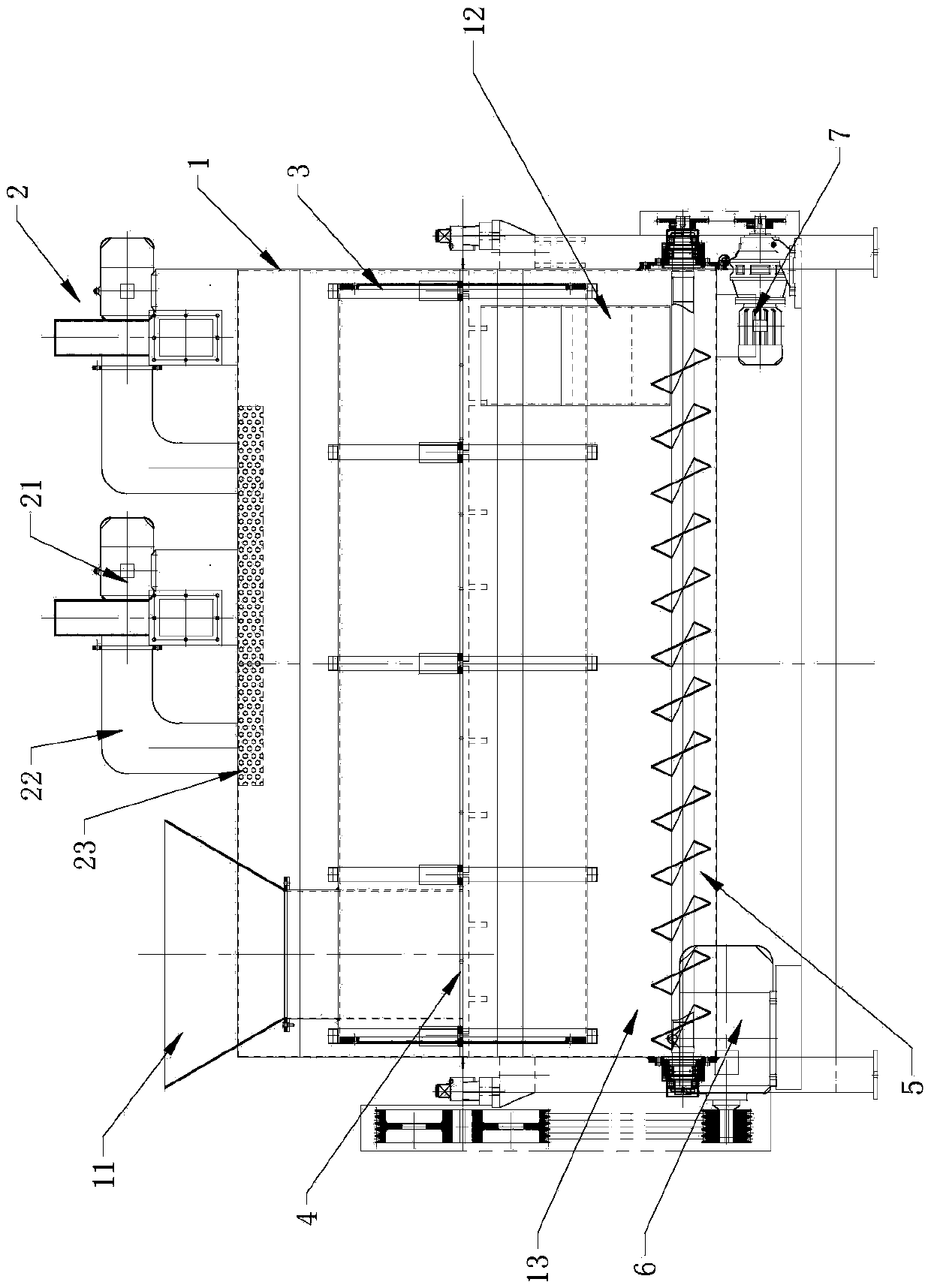

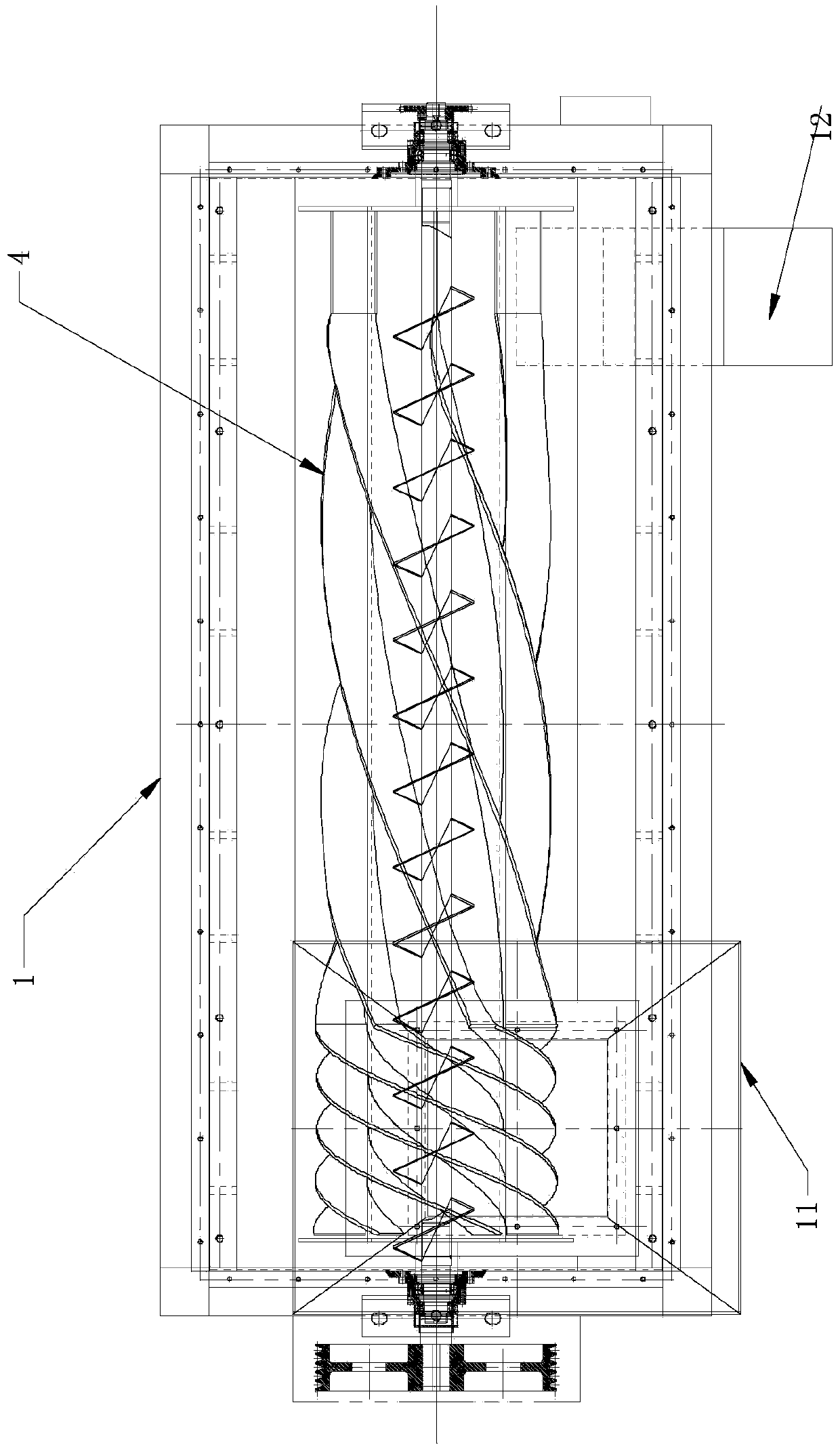

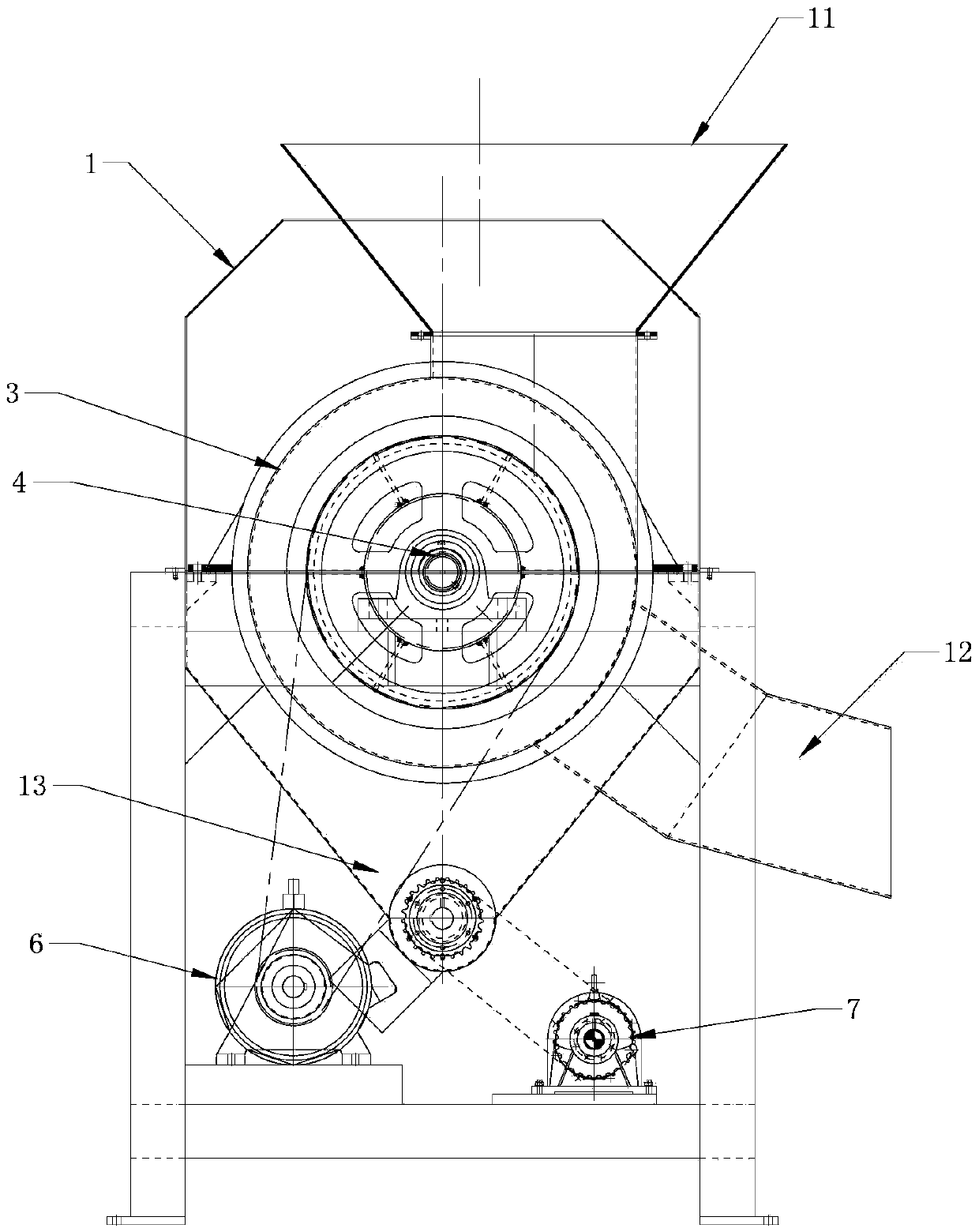

[0021] Such as Figures 1 to 4 As shown, a plastic film vegetation separator includes a casing 1, a sieve drum 3, a main shaft 4, and a dust suction device 2. The casing 1 adopts a split structure, including an upper casing 1 and a lower casing 1, and the upper casing 1 Bolts are fixed between the casing 1 and the lower casing 1, and the upper casing 1 is provided with a feed hopper 11 communicated with the feeding port of the sieve cylinder 3, while the impurity collection chamber 13 is arranged in the lower casing 1, and The lower casing 1 is provided with a discharge nozzle 12 communicating with the discharge port of the screen drum 3 . The screen cylinder 3 is axially and horizontally fixed in the casing 1. One end of the screen cylinder 3 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com