Preparation method of natural milk flavor essence

A milk-flavored flavor and natural technology, applied in the field of preparation of natural milk-flavored flavor, can solve the problems of inconsistent aroma, unstable aroma, weak strength, etc., and achieve the effect of pure aroma, reduced impact, and good pleasure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

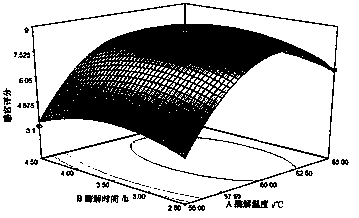

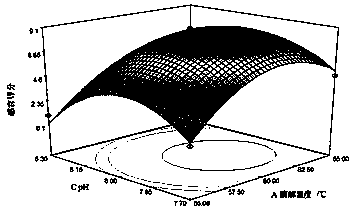

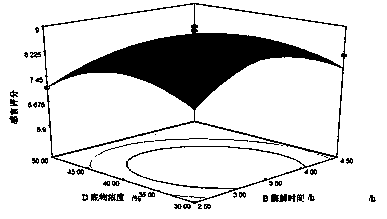

Image

Examples

Embodiment 1

[0043] A preparation method of natural milk flavor essence, specifically comprises the following steps:

[0044] (1), homogeneous emulsification

[0045] Add 0.15g of emulsifier to 6 parts of 10g of cream respectively, mix them in a warm water bath, then add 40mL of deionized water respectively, after mixing, control the speed of 10000r / min on a high-speed homogeneous shearing machine for homogenization Emulsified for about 10 minutes to obtain 6 parts of emulsion;

[0046] Described cream, emulsifier and deionized water are calculated by mass ratio, that is, cream: emulsifier: deionized water is 10:0.15:40;

[0047] Described emulsifier is glyceryl monostearate;

[0048] (2), pasteurization

[0049] Put the 6 parts of the emulsion obtained in step (1) into an enzymatic hydrolysis tank, connect the super constant temperature water bath to the magnetic stirrer device, control the temperature of the super constant temperature water bath to 85°C, and pasteurize the 6 parts...

Embodiment 2

[0056] A preparation method of natural milk flavor essence, specifically comprises the following steps:

[0057] (1), homogeneous emulsification

[0058] Add 0.15g of emulsifier to 10g, 20g, 25g, 30g, 40g, and 50g of cream respectively, mix them in a warm water bath, and then add 40g, 30g, 25g, 20g, 10g, and 0g of deionized water respectively to control The total mass of cream and deionized water is 50g, and the concentration of cream, that is, the percentage of cream in the total mass of cream and deionized water is 20%, 40%, 60%, 80%, 100% respectively, and mix well After that, carry out homogeneous emulsification on a high-speed homogeneous shearing machine with a control speed of 10000r / min for about 10 minutes, and obtain 6 parts of emulsions respectively corresponding to different cream contents;

[0059] Described emulsifier is glyceryl monostearate;

[0060] (2), pasteurization

[0061] Put the 6 parts of emulsion corresponding to different cream contents obtained i...

Embodiment 3

[0069] A preparation method of natural milk flavor essence, specifically comprises the following steps:

[0070] (1), homogeneous emulsification

[0071] Add 0.15g of emulsifier to 7 parts of 10g of cream, mix them in a warm water bath, then add 40mL of deionized water, mix well, and then control the speed of 10000r / min on a high-speed homogeneous shearing machine for homogeneous emulsification About 10min, get 7 parts of emulsion;

[0072] Described cream, emulsifier and deionized water are all calculated by mass ratio, that is, cream: emulsifier: deionized water is 10:0.15:40;

[0073] Described emulsifier is glyceryl monostearate;

[0074] (2), pasteurization

[0075] Put the 7 parts of the emulsion obtained in step (1) in an enzymatic hydrolysis tank, and connect the super constant temperature water bath to the magnetic stirrer device, and control the temperature of the super constant temperature water bath to 85 °C, and pasteurize the 7 parts of the emulsion Sterilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com