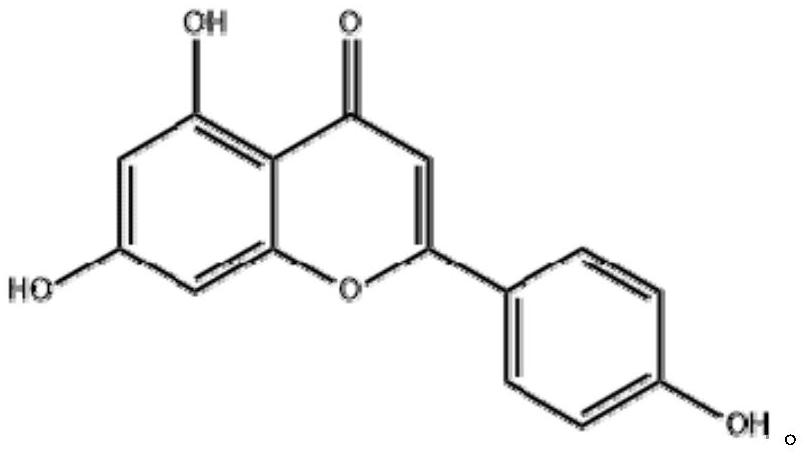

Method for extracting apigenin from Ostericum sieboldii and application

An apigenin and extraction technology, which is applied to medical preparations, pharmaceutical formulations, plant raw materials and other directions containing active ingredients, can solve the problems of inability to excrete uric acid normally, low excretion, and undisclosed apigenin, and optimize the extraction sequence. , The effect of reducing uric acid, improving yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for extracting apigenin from celery, comprising the steps of:

[0053] (1) Dry and pulverize the celery, add 5 times the amount of solvent A to extract, add 3% xylanase for enzymolysis for 10 minutes, and then add 5% glucosidase, the solvent A is ethylene glycol, iso A mixed solvent of propanol and water, the volume ratio of the three is 2:1:1, the extraction temperature is 30°C, the total extraction time is 1h, and the extract is concentrated to 1 / 5 of the original volume to obtain substance A;

[0054] (2) Substance A is successively added into equal volumes of petroleum ether, chloroform and ethyl acetate for extraction, the extraction layers of chloroform and ethyl acetate are collected, dried respectively, and combined to obtain a crude product;

[0055] (3) The crude product is dissolved with 30% ethanol of 3 times the amount, and the D101 macroporous adsorption resin is used for adsorption, and the solvent D is used for elution, and the solvent D is a mi...

Embodiment 2

[0058] A method for extracting apigenin from celery, comprising the steps of:

[0059] (1) Dry and pulverize the celery, add 10 times the amount of solvent A to extract, add 8% xylanase for enzymolysis for 25min, then add 10% glucosidase, the solvent A is ethylene glycol, iso A mixed solvent of propanol and water, the volume ratio of the three is 4:1:3, the extraction temperature is 40°C, the total extraction time is 2h, and the extract is concentrated to 1 / 8 of the original volume to obtain substance A;

[0060] (2) Substance A is successively added into equal volumes of petroleum ether, chloroform and ethyl acetate for extraction, the extraction layers of chloroform and ethyl acetate are collected, dried respectively, and combined to obtain a crude product;

[0061] (3) The crude product is dissolved with 5 times of 90% ethanol, adsorbed by D101 macroporous adsorption resin, and eluted by solvent D, which is a mixed solvent of chloroform and methanol, and the volume ratio of...

Embodiment 3

[0064] A method for extracting apigenin from celery, comprising the steps of:

[0065] (1) Dry and pulverize the celery, add 8 times the amount of solvent A to extract, add 5% xylanase for enzymolysis for 15min, then add 7% glucosidase, the solvent A is ethylene glycol, iso A mixed solvent of propanol and water, the volume ratio of the three is 3:1:2, the extraction temperature is 35°C, the total extraction time is 1.5h, and the extract is concentrated to 1 / 6 of the original volume to obtain substance A;

[0066] (2) Substance A is successively added into equal volumes of petroleum ether, chloroform and ethyl acetate for extraction, the extraction layers of chloroform and ethyl acetate are collected, dried respectively, and combined to obtain a crude product;

[0067] (3) The crude product is dissolved with 4 times of 60% ethanol, adsorbed by D101 macroporous adsorption resin, and eluted by solvent D, which is a mixed solvent of chloroform and methanol, and the volume ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com