Automatic stacking machine for pole plates

An automatic stacking and plate technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, final product manufacturing, etc., can solve the problem that lead dust is harmful to operators, and achieve work efficiency, device operation convenience, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

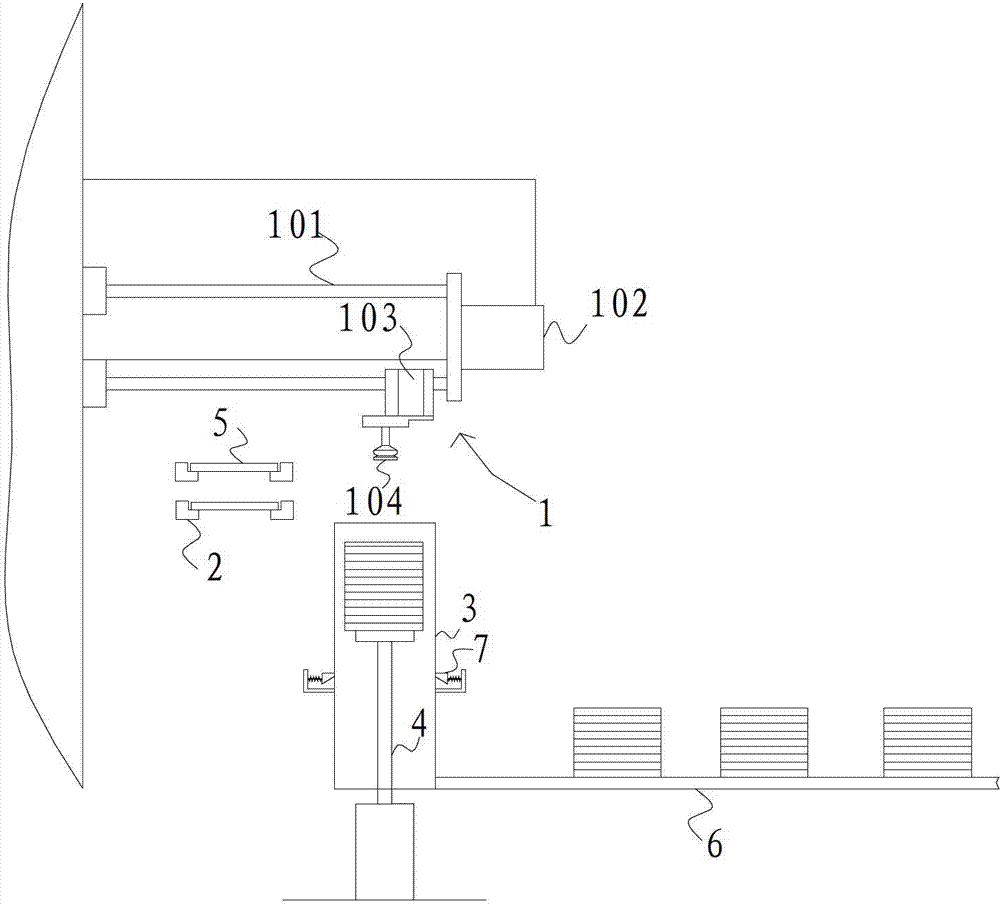

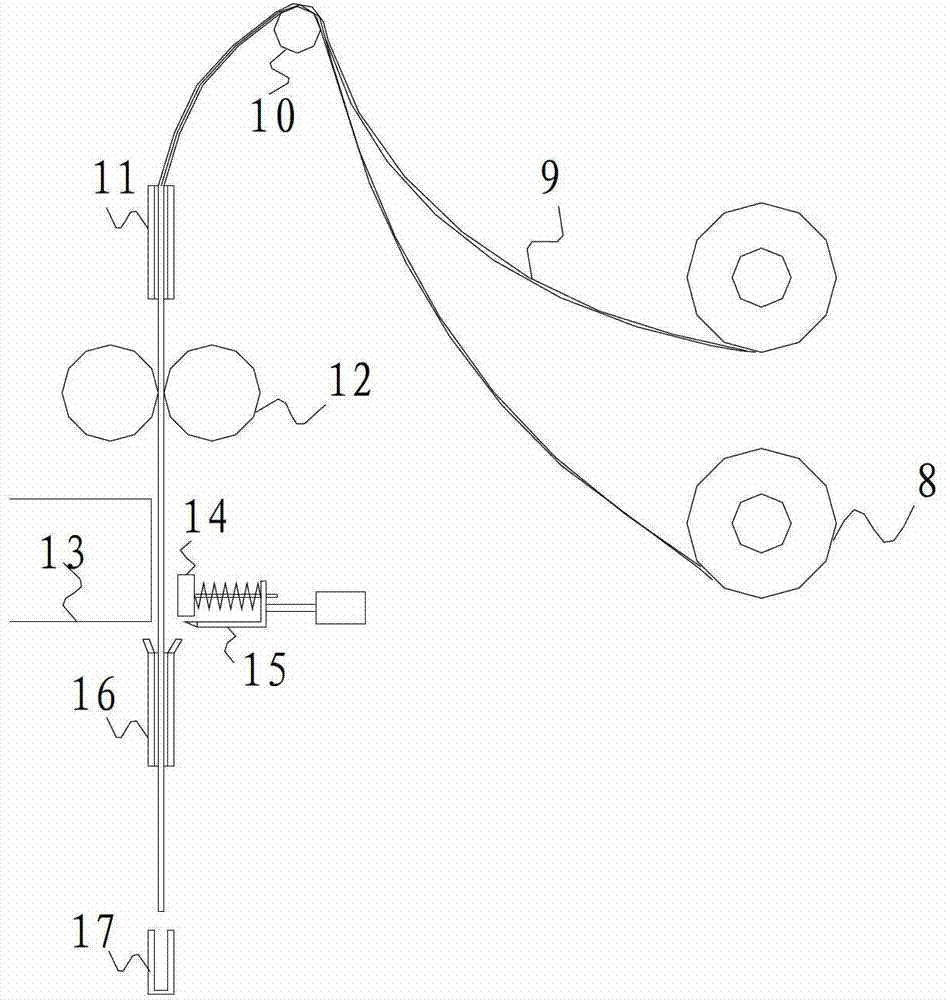

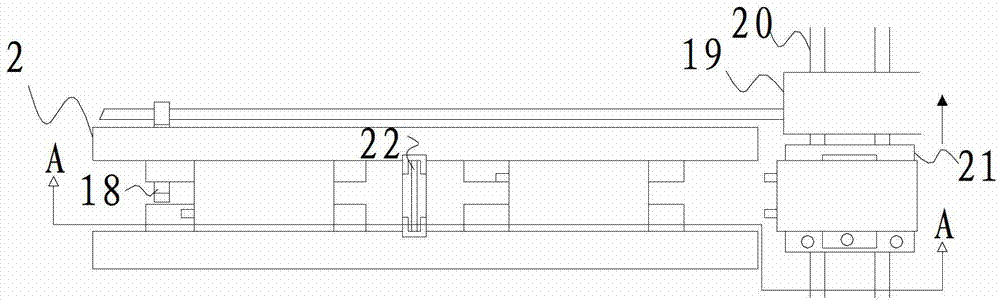

[0040] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, an automatic plate stacking machine includes a plate supply mechanism, a separator supply mechanism and a plate stacking mechanism.

[0041] The structure of the plate supply mechanism is as follows: figure 1 As shown, it includes a pole plate conveyor belt 6; a pole plate storage frame 3, a pole plate ejector pin 4 and an ejector pin driving cylinder.

[0042] The plate conveyor belt 6 adopts a conventional conveyor belt, and two pole plate conveyor belts 6 are arranged parallel to each other to convey the positive plate and the negative plate respectively, and a plate receiving basket 3 is correspondingly arranged at the output end of each plate conveyor belt 6. The pole plate entrance of the storage basket 3 is docked with the output end of the pole plate conveying section 6 , and the pole plate 5 runs along the pole plate conveyor belt 6 to the output end of the pole plate conveyor belt 6 and then e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com