A zinc oxide nano-pencil array electrode and its preparation method and application

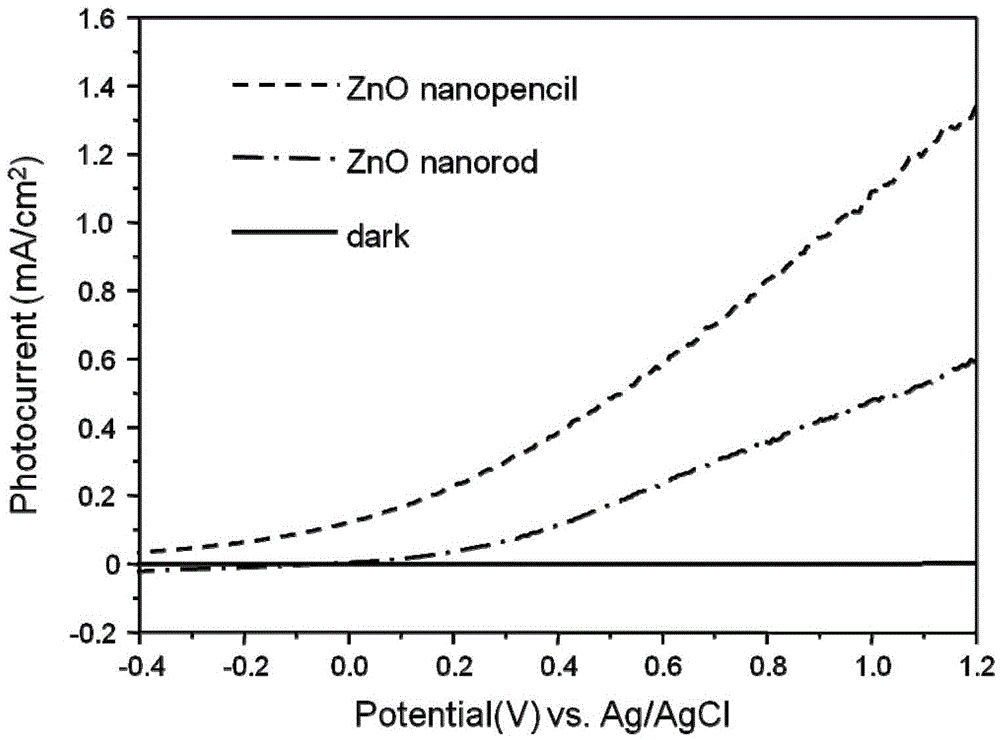

A zinc oxide nanometer and array electrode technology, applied in the field of photoelectrochemistry, can solve the problems of low photoelectric efficiency, difficulty in efficiently utilizing sunlight, etc., and achieve the effects of low cost, inhibition of recombination, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of ZnO seed layer

[0036] ①The FTO conductive glass was sonicated in deionized water, acetone and ethanol solution for 10 minutes successively, washed with deionized water, and dried for use;

[0037] 2. The ethanolic solution of zinc acetate dihydrate of 5mmol / L is prepared: 0.0548g of zinc acetate dihydrate is mixed with 50ml of absolute ethanol, and stirred until completely dissolved to obtain the ethanolic solution of zinc acetate dihydrate of 5mmol / L;

[0038] ③ Evenly drop the zinc acetate dihydrate ethanol solution onto the FTO conductive glass, then dry, and repeat the above operation 10 times;

[0039] ④ The above substrate is calcined in an air atmosphere for 30 minutes at 350° C. to obtain a ZnO seed layer.

[0040] (2) Preparation of ZnO nanorod arrays

[0041] ①Preparation of Zn(NO 3 ) 2 ·6H 2 A mixed aqueous solution A of O and HMTA, in which Zn 2+ The concentration of HMTA and 50mmol / L;

[0042] ②Place the FTO conductive glass coat...

Embodiment 2

[0055] (1) The preparation of the ZnO seed layer is the same as that of Example 1.

[0056] (2) The preparation of ZnO nanorod arrays is the same as that in Example 1.

[0057] (3) Preparation of ZnO nanopencil arrays

[0058] ① Prepare a mixed aqueous solution B of zinc source and ascorbic acid, in which Zn(NO 3 ) 2 ·6H 2 The concentrations of O and HMTA were 10 mmol / L, and the concentration of ascorbic acid was 0.375 mmol / L;

[0059] ②Place the FTO conductive glass with ZnO nanorod arrays in mixed solution B, place the side with ZnO nanorod arrays facing down, immerse it in the solution and close to the liquid surface, and react at 90°C for 4 hours ZnO nanopencil arrays were prepared;

[0060] ③ After the reaction, the FTO conductive glass was taken out, rinsed with deionized water, and dried.

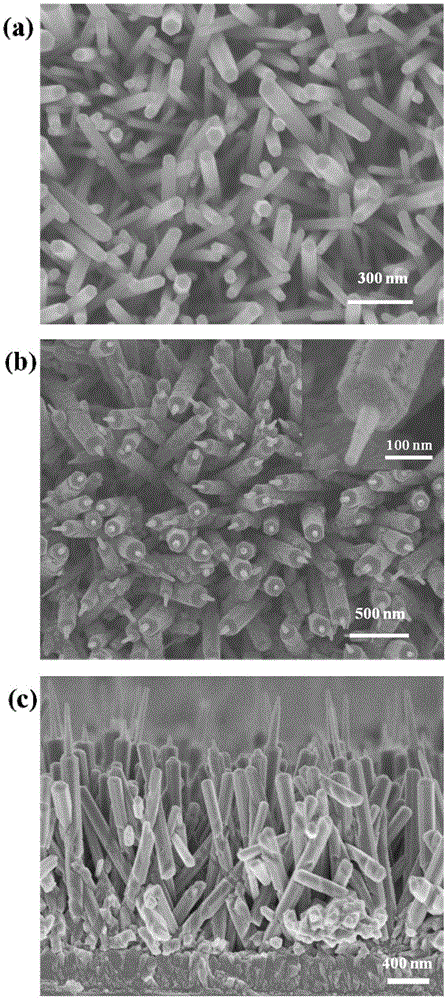

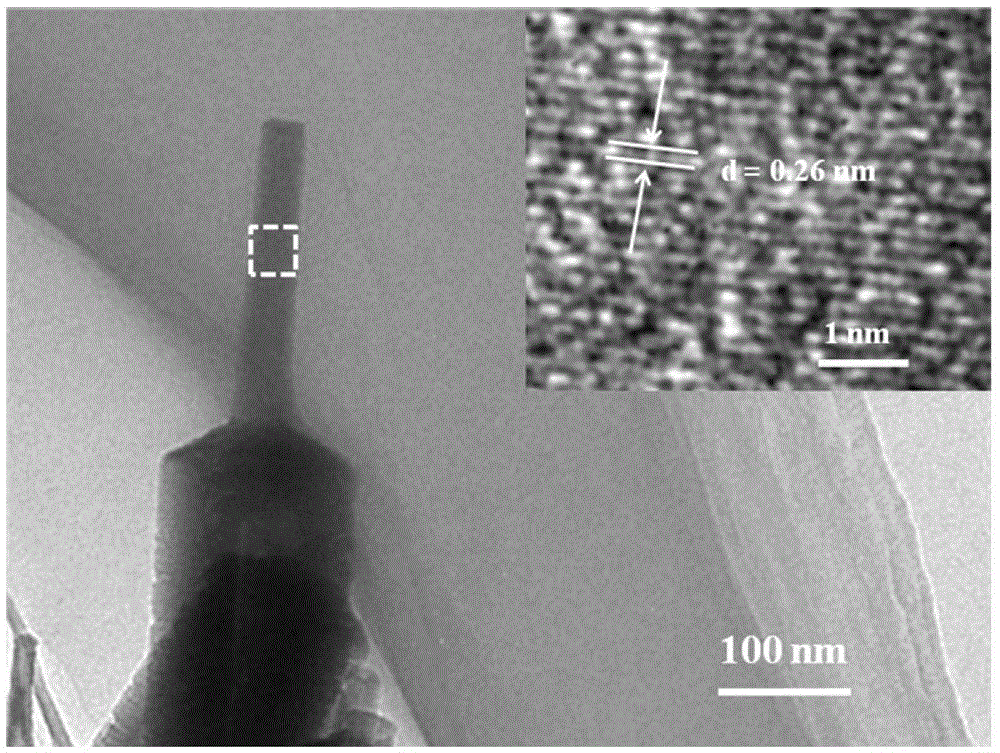

[0061] The experimental results show that the diameter of the backbone nanorods of the ZnO nanopencil is 100-150nm and the length is 1.5-2μm; the diameter of the tip of the ZnO...

Embodiment 3

[0064] (1) The preparation of the ZnO seed layer is the same as that of Example 1.

[0065] (2) Preparation of ZnO nanorod arrays

[0066] ①Preparation of Zn(NO 3 ) 2 ·6H 2 A mixed aqueous solution A of O and HMTA, in which Zn 2+ The concentration with HMTA is 40mmol / L;

[0067] ②Place the FTO conductive glass coated with the ZnO seed layer in the mixed solution A, place the side coated with the ZnO seed layer down, immerse it in the solution and close to the liquid surface, and react at 85°C for 2 hours. ZnO nanorod arrays;

[0068] ③ After the reaction, the FTO conductive glass was taken out, rinsed with deionized water, and dried.

[0069] (3) Preparation of ZnO nanopencil arrays

[0070] ① Prepare a mixed aqueous solution B of zinc source and ascorbic acid, in which Zn(NO 3 ) 2 ·6H 2 The concentration of O and HMTA is 5mmol / L, and the concentration of ascorbic acid is 0.1875mmol / L;

[0071] ②Place the FTO conductive glass with ZnO nanorod arrays in mixed solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com