Drill bit capable of enabling well wall to be ceramic

A ceramization and drill bit technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve problems such as the inability of supporting equipment to achieve industrial application, speed up the exploration and development of oil and gas resources, and the effect of mechanical penetration rate is not significant enough, so as to reduce drilling cost, shorten the well construction period, and improve the effect of rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

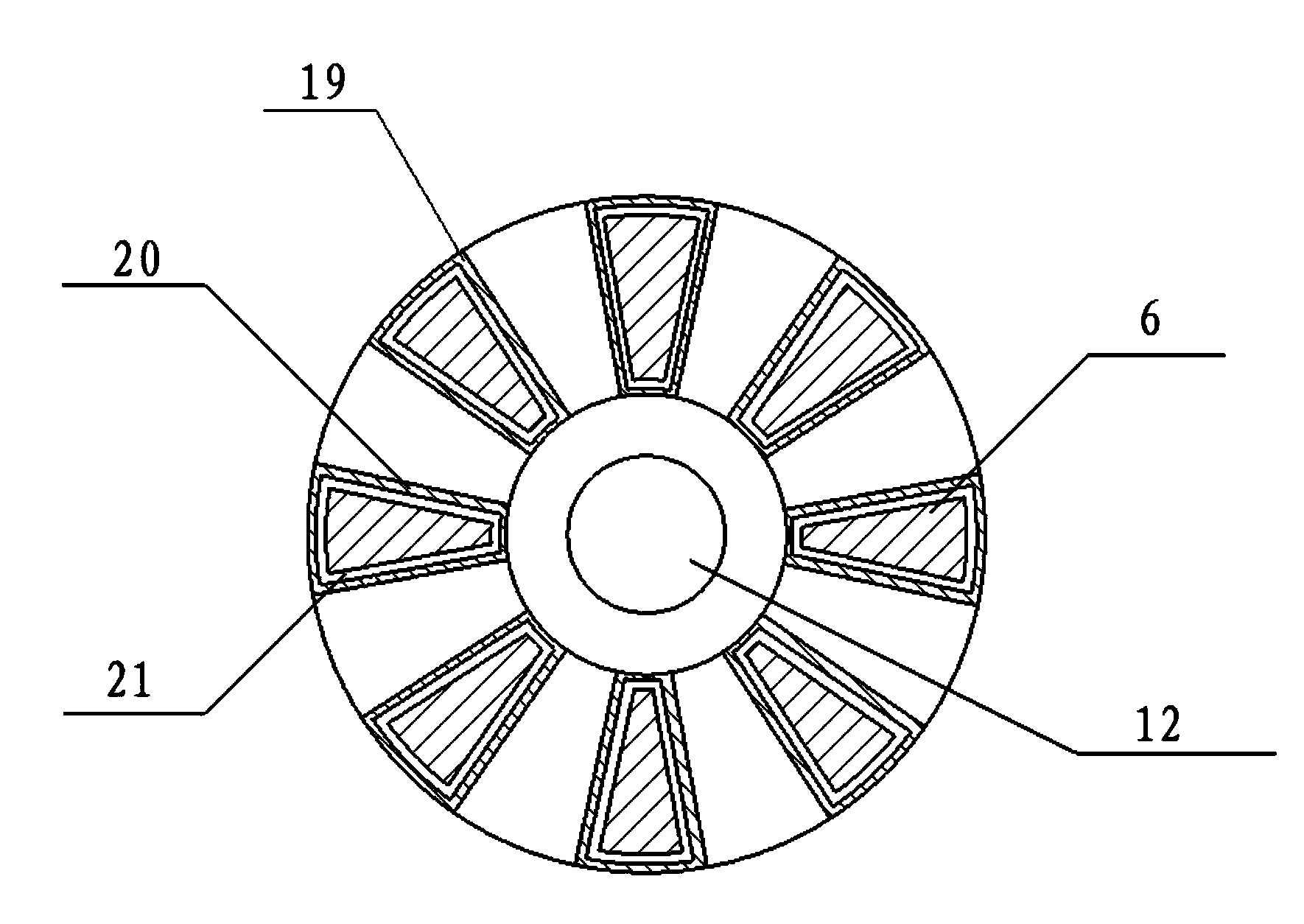

[0044] like Figure 4 As shown, the structure of embodiment 2 is basically the same as that of embodiment 1, the difference is that the outer circumference of the drill bit body 3 and the drill bit cutting teeth 6 are all provided with a high temperature heat insulation layer 16 ( Figure 5 The high-temperature heat insulation layer 16 is set on the outer periphery of the drill body 3 as an example for illustration). The high-temperature insulation layer 16 transmits the thermal energy of radiation to the drill bit body 3 and the drill bit cutter 6 to insulate the rock, so that the temperature of the drill bit body 3 and the drill bit cutter 6 remains at a certain temperature, further improving the service life of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com