Method for arranging water stops in box body jacking process

A technology for waterstops and boxes, which is applied in the field of setting waterstops in the process of box jacking, and can solve problems such as labor intensity, large amount of engineering, large damage surface, and damage to waterstops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

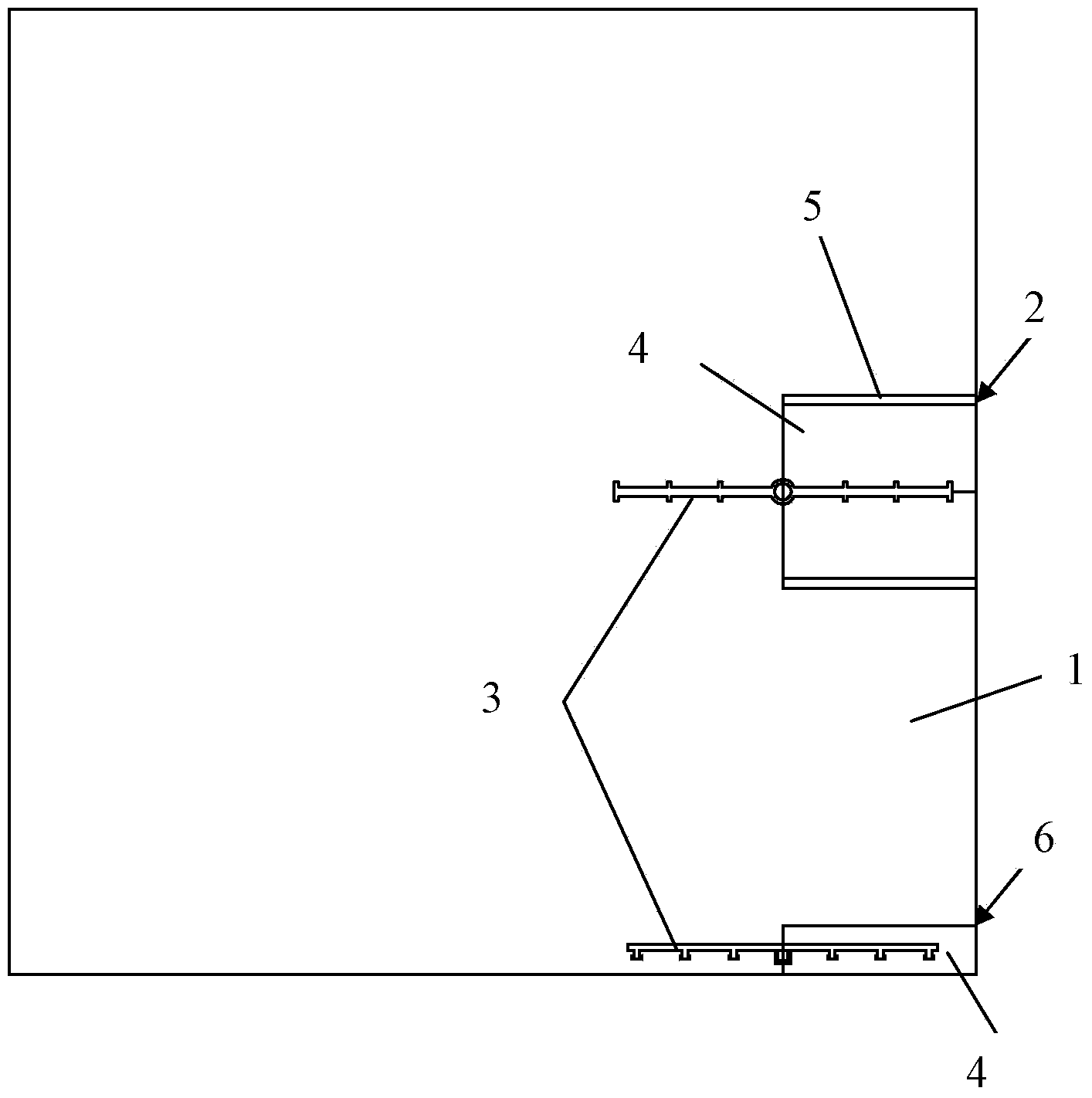

[0015] The method for setting the water stop belt during the jacking process of the box body provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] Such as figure 1 As shown, the method for setting the water stop belt during the jacking process of the box body provided by the present invention includes the following steps in order:

[0017] 1) When prefabricating the box body 1, a circle of grooves 2 and 6 in the shape of a mouth are formed on the middle part and the inner edge of the front face respectively, and at the same time, one side of the two circles of waterstop 3 is prefabricated along the length direction of the box body 1. Buried in the concrete inside the grooves 2 and 6, the other side is exposed in the grooves 2 and 6; the waterstop 3 in the groove 2 is a mid-buried waterstop, and the waterstop in the groove 6 Belt 3 is an externally attached waterstop;

[0018] 2) Se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com