Reinforcing steel bar bending machine applied to engineering construction

A bending machine and steel bar technology, applied in the field of steel bar bending machines, can solve problems such as large impact of punches, cracking, and strength damage of steel bar bending, so as to improve bending efficiency, reduce adverse effects, and high bending efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

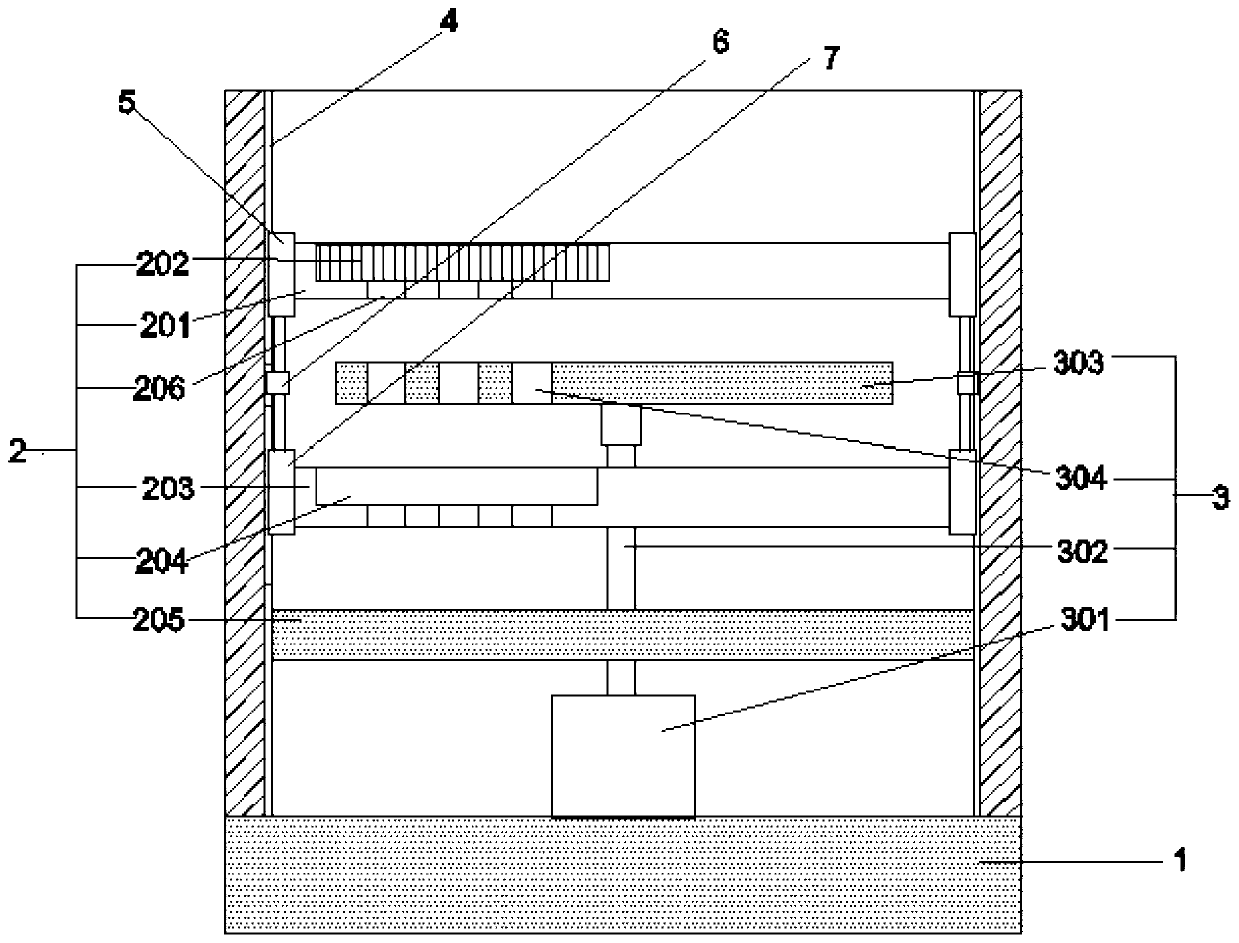

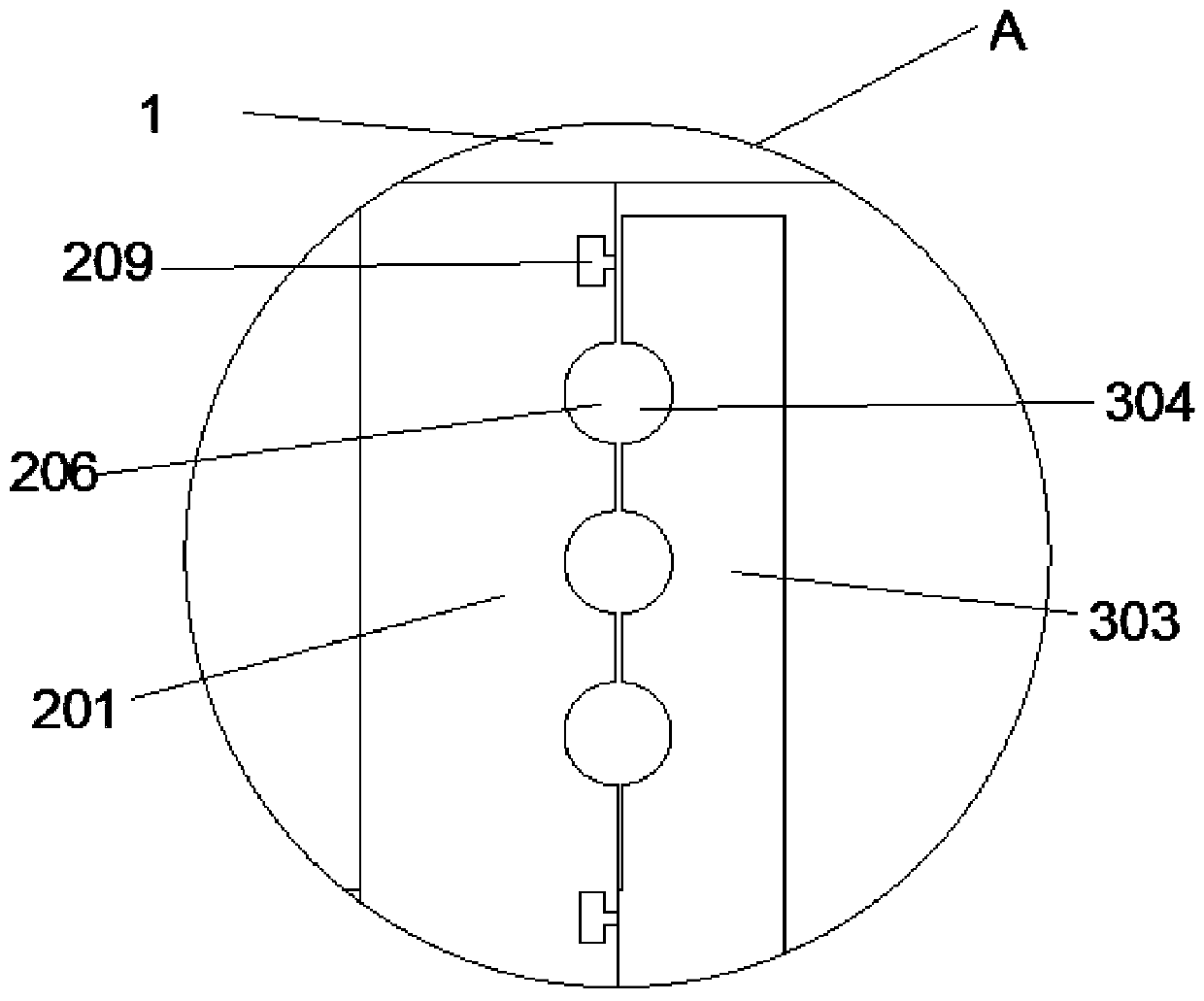

[0025] See Figure 1~6 In an embodiment of the present invention, a steel bar bending machine for engineering construction, the steel bar bending machine includes a base 1, a support base, an axial bending mechanism 2 and a radial bending mechanism 3, wherein the base 1 The upper end is provided with a support base extending vertically upwards, the support base is provided with the axial bending mechanism and the radial bending mechanism, characterized in that the axial bending mechanism is located on the axis of the steel bar to be bent To both ends to apply a vertical axial bending force to the steel bar; the radial bending mechanism initially applies a bending force in the radial direction of the steel bar; it also includes a controller that controls the axial top The bending force and the bending displacement of the bending mechanism 2 and the radial bending mechanism 3, and when the steel bar is initially bent, the controller controls the radial bending mechanism to bend w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com