Mounting lock catch used for plastic floor

A plastic floor and locking technology, which is applied to floors, buildings, building structures, etc., can solve the problems of broken floor assembly structures, poor control of force, and high manufacturing costs of floor assembly structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

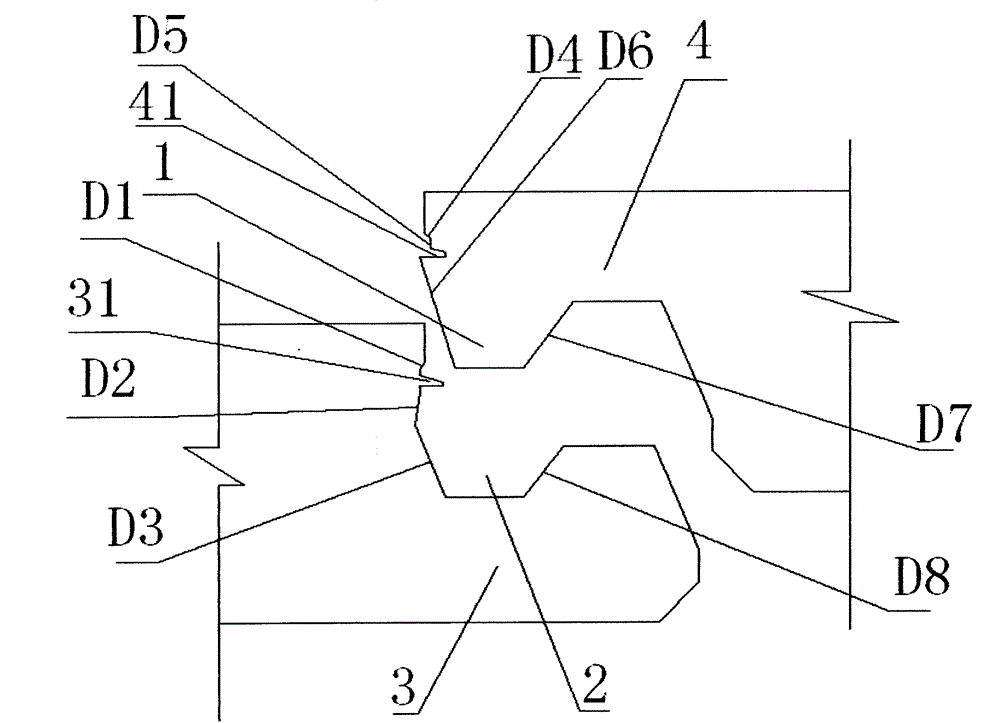

[0024] Such as figure 2 As shown, the left side wall of the recess 2 of the tenon 3 is composed of a vertical facade part, a first chamfer D1 part, a second chamfer D2 part, and a third chamfer D3 part, and the right side of the recess 2 is provided with The female tenon head including the eighth chamfer D8, the left front elevation of the convex part 1 of the male tenon 4 is composed of a vertical facade part, a fourth chamfer D4 part, a fifth chamfer D5 part, and a sixth chamfer D6 Partial composition, the right side of the convex part 1 is provided with a female tenon head placement groove containing the seventh chamfer D7, the left side wall of the female tenon 3 far from the head end of the female tenon is provided with a protruding part 31, and the male tenon A groove 41 having the same shape as the protrusion is provided on the left front elevation of the protrusion 2 of 4, and the maximum width of the front section of the protrusion 31 is less than or equal to the ent...

Embodiment 2

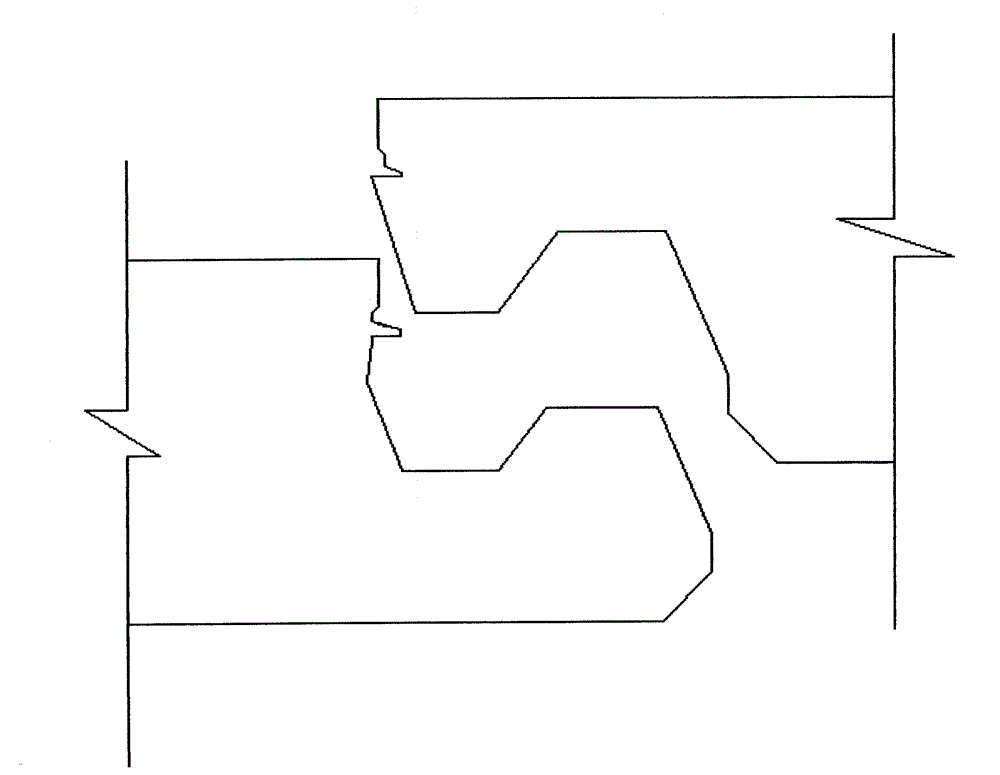

[0032] Such as Figure 6 As shown, in this embodiment, the cross section of the protruding part 31 is triangular, and the cross section of the corresponding groove 41 is concave triangle, and other structural parts are the same as those in the first embodiment.

Embodiment 3

[0034] Such as Figure 7 As shown, in this embodiment, the section of the protruding part 31 is semicircular, and the section of the corresponding groove 41 is semicircular, and other structural parts are the same as those of the first embodiment.

[0035] To sum up, the cross-sectional shapes of the protruding part 31 and the groove 41 are not limited to the above three types, and different shapes can be set according to the needs. direction displacement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com