Method for calculating residual slag amount of converter in accordance with tilting angle of converter

A tilting angle, converter technology, applied in calculation, manufacturing converter, electrical digital data processing, etc., can solve the problems of inaccurate weight value, increased equipment investment, converter smelting process and the influence of secondary model calculation accuracy, etc., to save The effect of investment, control algorithm is simple, easy to implement and apply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

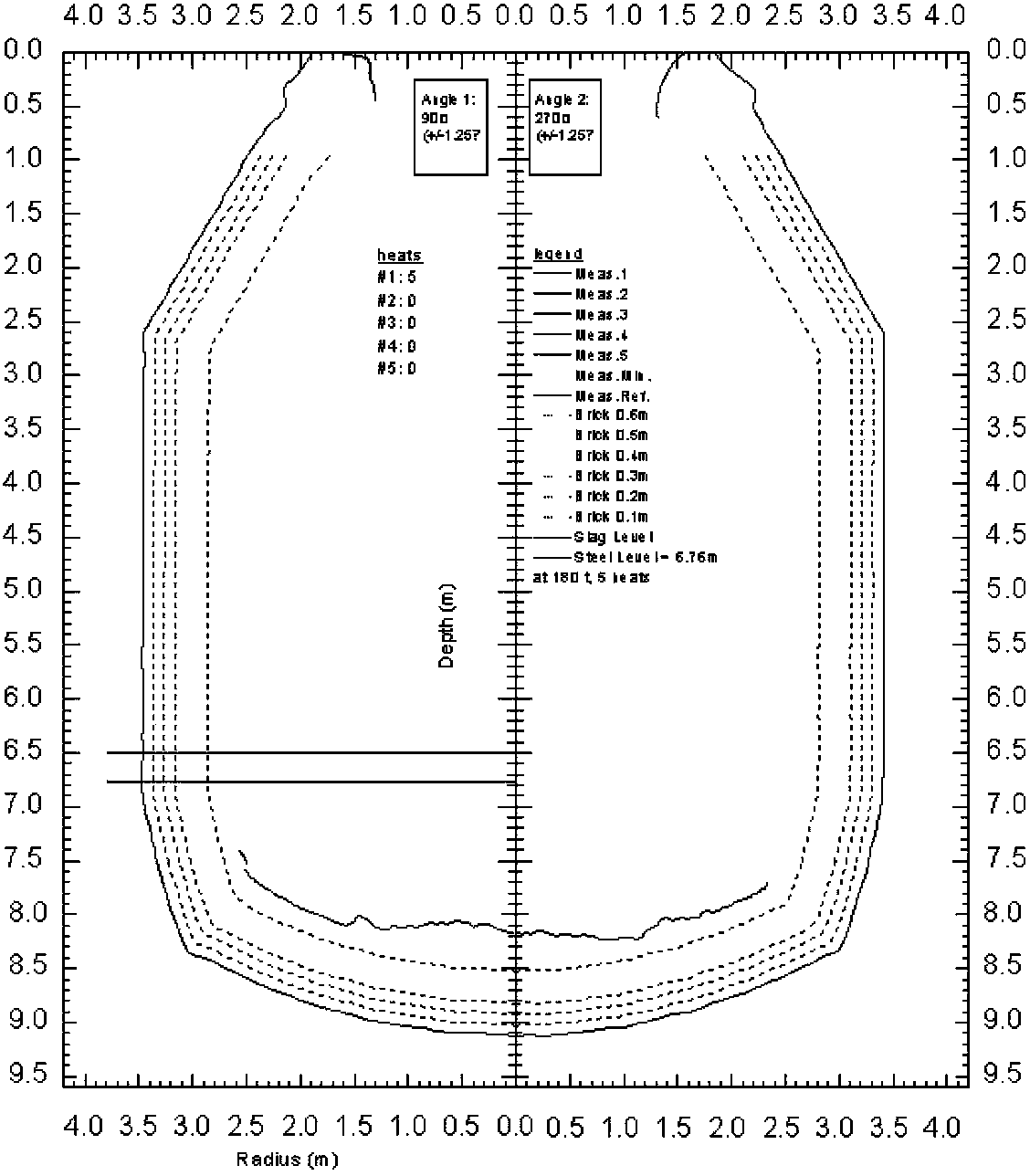

[0036] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

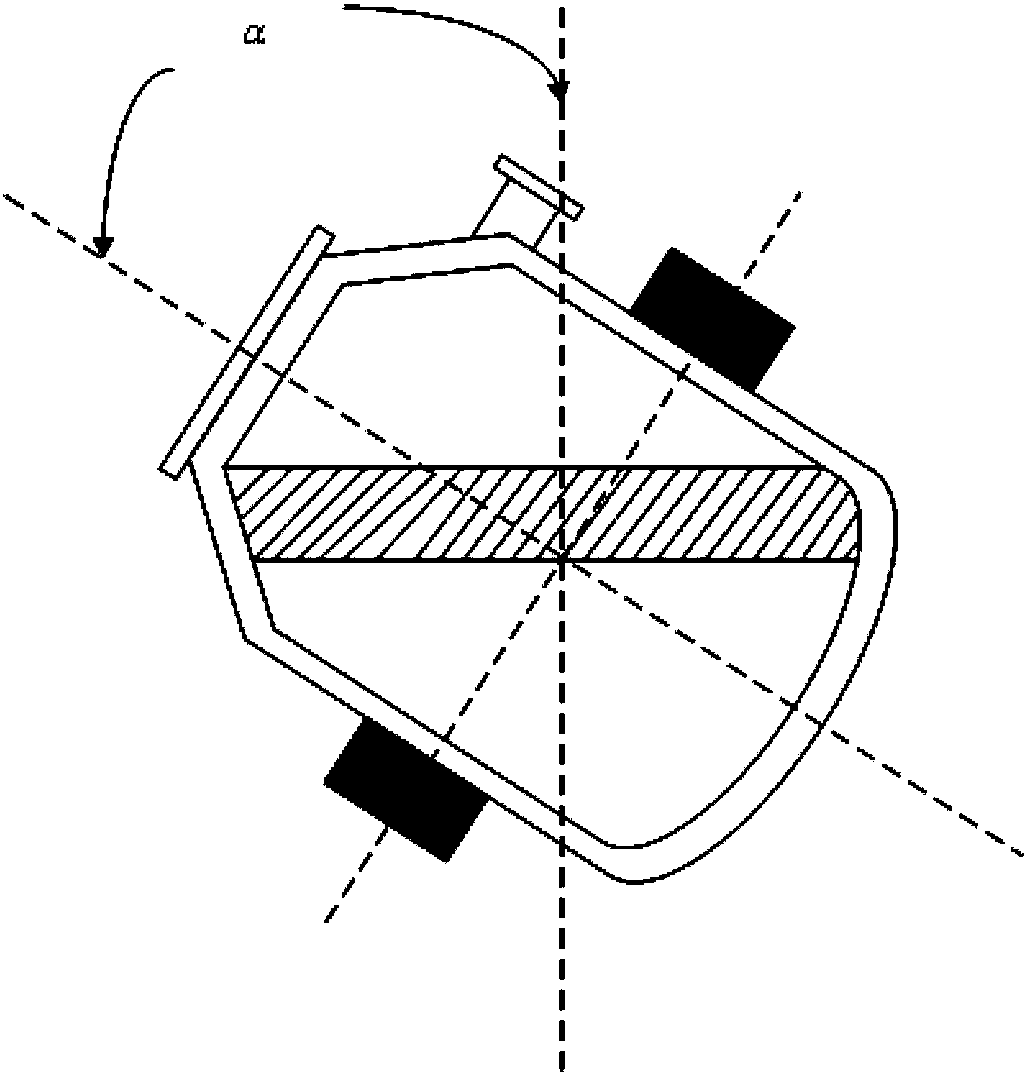

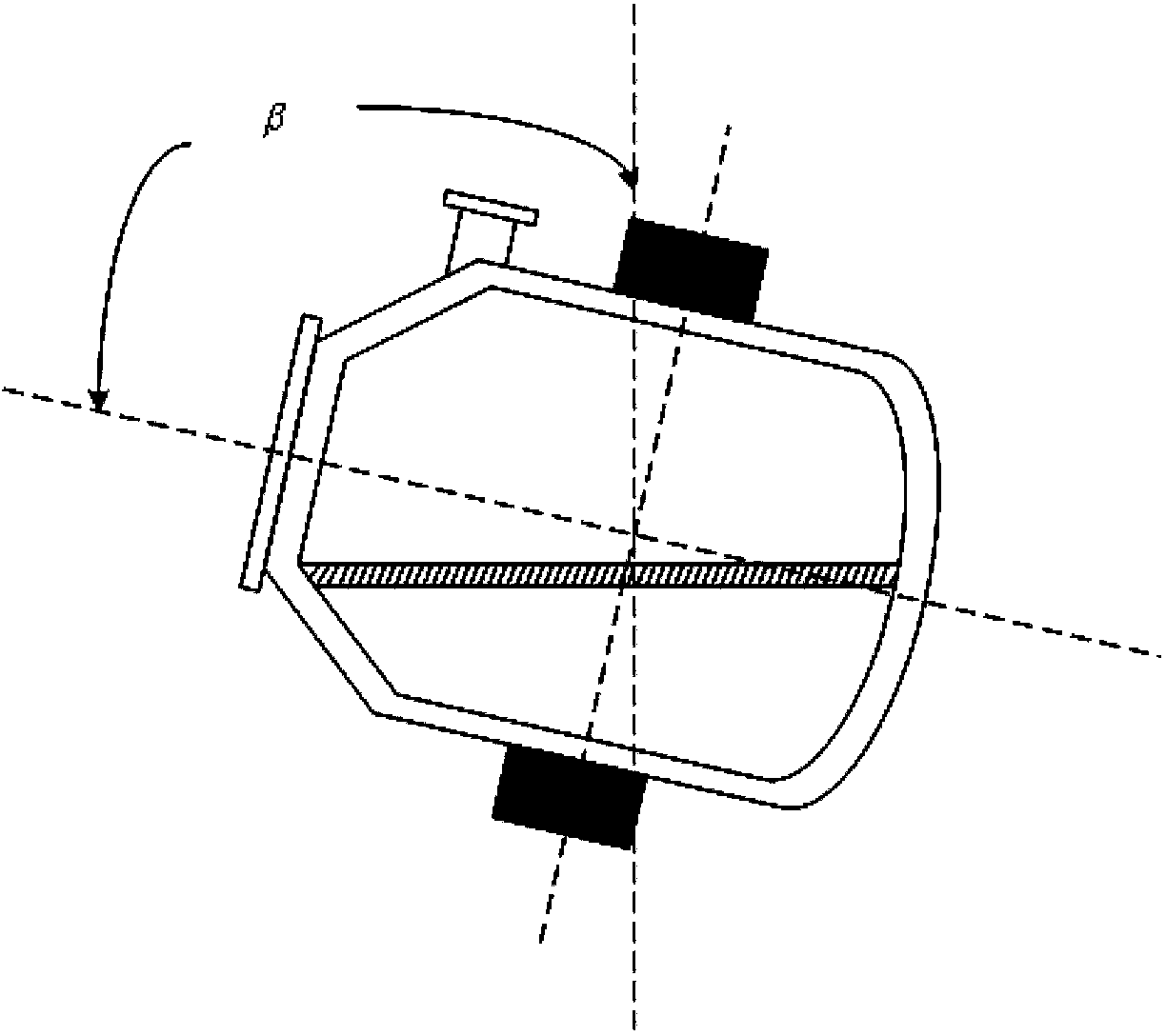

[0037] A method of calculating the amount of slag remaining in the converter according to the tilting angle of the converter in this embodiment is applied to a 180t converter in a steel plant. The process of slag dumping is shown in Figure 1 .

[0038] The implementation process of the technical solution is described in detail as follows.

[0039] Since the specific weight of the forehearth slag cannot be determined, the converter needs to be emptied before the calculation, and since the slag adhering to the furnace mouth may have a certain impact on the observation of the critical angle, maintenance personnel are required to clean the furnace mouth, and the furnace lining measurement data must be Export ahead of time.

[0040] The operator in front of the furnace observes the critical angle α when the slag will not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com