Device and method for dehydrating heavy sump oil

A dehydration device and heavy dirty oil technology, applied in the direction of mechanical dehydration/demulsification, etc., can solve problems such as catalyst poisoning, dirty oil with salt, high water content, sewage with oil, etc., and achieve simple structure and easy operation of the production device Convenience, Adaptable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

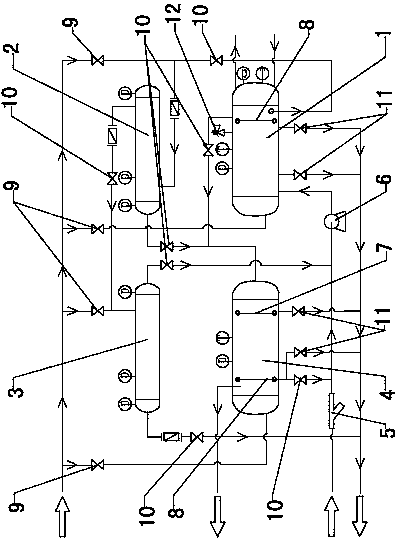

[0028] A heavy dirty oil dehydration device and method will be further described below in conjunction with the accompanying drawings.

[0029] Refer to attached figure 1 : After the dirty oil in the tank area is drawn out, it first enters the Y-type filter 5 to filter out solid-phase impurities that are easy to form blockages in the pipeline, and then enters the steam heat exchanger 1 after being pressurized by the booster pump 6 along the pipeline. After the heavy dirty oil exchanges heat with the medium-pressure steam in the steam heat exchanger 1, the temperature rises to 80~130°C, and then the heavy dirty oil outlet pipe in the middle and lower part of the steam heat exchanger 1 passes through the pipeline with the flow regulating valve 10 Introduce cyclone dehydrator 2. In the cyclone dehydrator 2, it is separated into a low water content sewage oil phase and a low oil content sewage phase, wherein the low water content sewage oil phase is discharged from the overflow po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com