Polyethylene naphthalate resin composition and preparation method thereof

A technology of polyethylene naphthalate and resin composition, applied in the field of polymer materials, can solve the problem of undiscovered thermal conductivity of PEN, and achieve the effects of improving mechanical properties and heat resistance, simple process and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

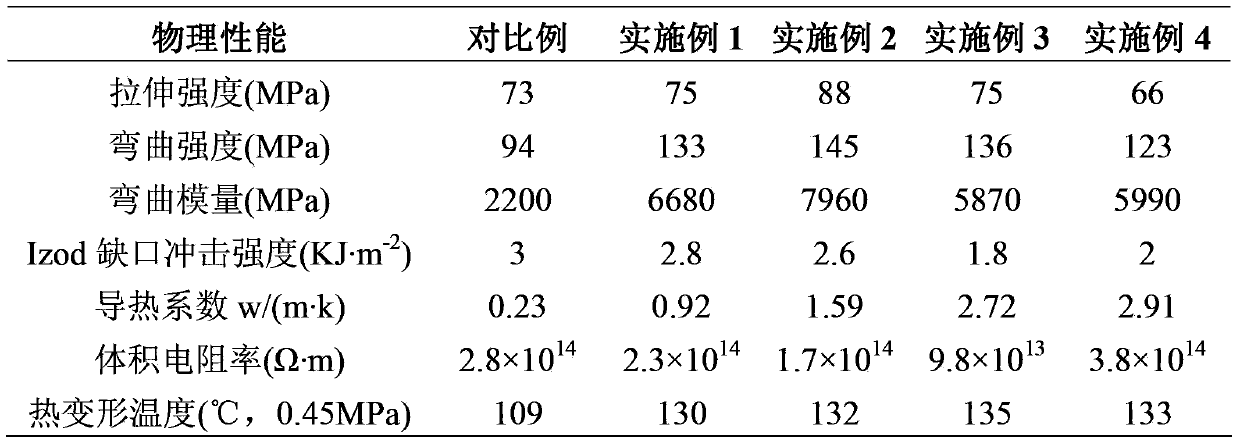

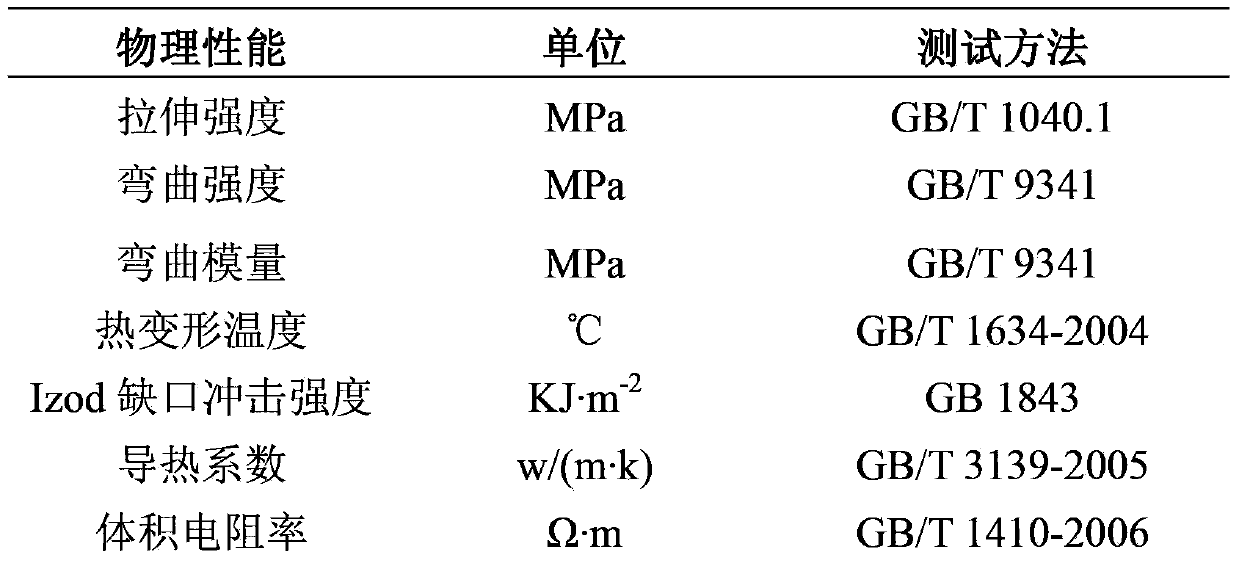

Examples

Embodiment 1

[0047] 45wt% polyethylene naphthalate resin (intrinsic viscosity 0.65), 5wt% EPDM rubber (propylene content 35%, purchased from Exxon Mobil Corporation), 5wt% maleic anhydride graft Polypropylene (maleic anhydride graft rate 3%, purchased from Shanghai Kumho Sunny Company), 35wt% 200 mesh alumina, 1wt% aminosilane coupling agent (KH550, purchased from Nanjing Shuguang Chemical Group Co., Ltd.) and 0.4wt% antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) stearyl propionate (IRGANOX1076, purchased from BASF company) and 0.6wt% antioxidant triphosphite (2,4-di-tert-butylphenyl) ester (IRGAFOS168, purchased from BASF company) was stirred in a high-speed mixer (same as above) for 5 minutes, after mixing evenly, after dropping into a twin-screw extruder (same as above), from the fiber Add 8wt% alkali-free glass fiber (T635B, with an average diameter of 13 microns, purchased from Taishan Glass Fiber Co., Ltd.) into the inlet, and extrude to pelletize. The length-to-diameter ratio of...

Embodiment 2

[0049] 43.3wt% polyethylene naphthalate resin (intrinsic viscosity 0.75), 5wt% EPDM rubber (35% propylene content, purchased from Exxon Mobil Corporation), 2wt% maleic anhydride Branch EPDM rubber (maleic anhydride graft rate 2%, purchased from Shanghai Kumho Sunny Company), 44wt% 300 mesh magnesium oxide (purchased from Xiamen Zhanfan Trading Co., Ltd.), 0.5wt% epoxy group Silane coupling agent (KH570, purchased from Nanjing Shuguang Chemical Group Co., Ltd.) and 0.2wt% antioxidant tris (2,4-di-tert-butylphenyl) phosphite (IRGAFOS168, purchased from BASF company) Stir in mixer (same as above) for 4 minutes, after mixing evenly, drop into twin-screw extruder (same as above), add 5wt% alkali-free glass fiber (T635B, average diameter is 13 microns, purchased from Taishan Glass Fiber Co., Ltd. company), extrusion granulation. The length-to-diameter ratio of the twin-screw extruder is 32, the controlled feeding speed is 9rpm, the screw speed is 200rpm, and the temperature of each...

Embodiment 3

[0051] 44wt% of polyethylene naphthalate resin (intrinsic viscosity 0.75), 8wt% of SBS (SBS4452, purchased from China Petroleum & Chemical Corporation Beijing Yanshan Branch), 7wt% of maleic anhydride grafted SBS ( Maleic anhydride graft rate 3.2%, purchased from Shanghai Kumho Sunny Company), 32wt% 300 purpose boron nitride (purchased from Xiamen Zhanfan Trading Co., Ltd.), 0.5wt% epoxy silane coupling agent (KH570 , purchased from Nanjing Shuguang Chemical Group Co., Ltd.) and 0.5wt% antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) stearyl propionate (IRGANOX1076, purchased from BASF company) Stir in the high-speed mixer (same as above) for 3 minutes. After mixing evenly, put it into the twin-screw extruder (same as above), and add 8wt% alkali-free glass fibers (T635B, with an average diameter of 13 microns, purchased from Taishan Glass) from the fiber inlet. Fiber Co., Ltd.), extrusion granulation. The length-to-diameter ratio of the twin-screw extruder is 40, the control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com