One-pot synthetic method for N-t-butyl-aminocarbonyl-3-methyl-L-valine

A technology of tert-butylaminocarbonyl and synthetic method, which is applied in the field of drug synthesis, can solve the problems of affecting the yield of final product, greatly affecting the pH, and long synthesis time, and achieves shortened reaction cycle, controllable conditions, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

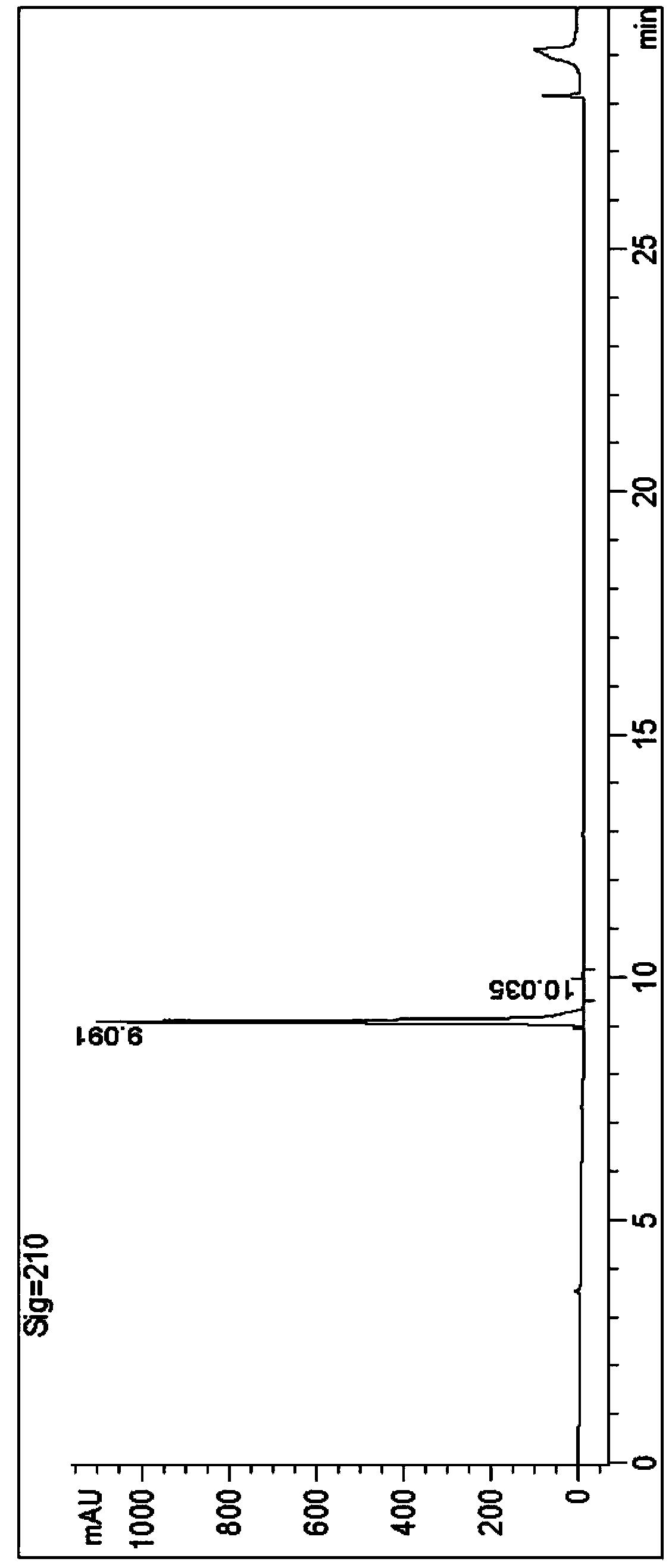

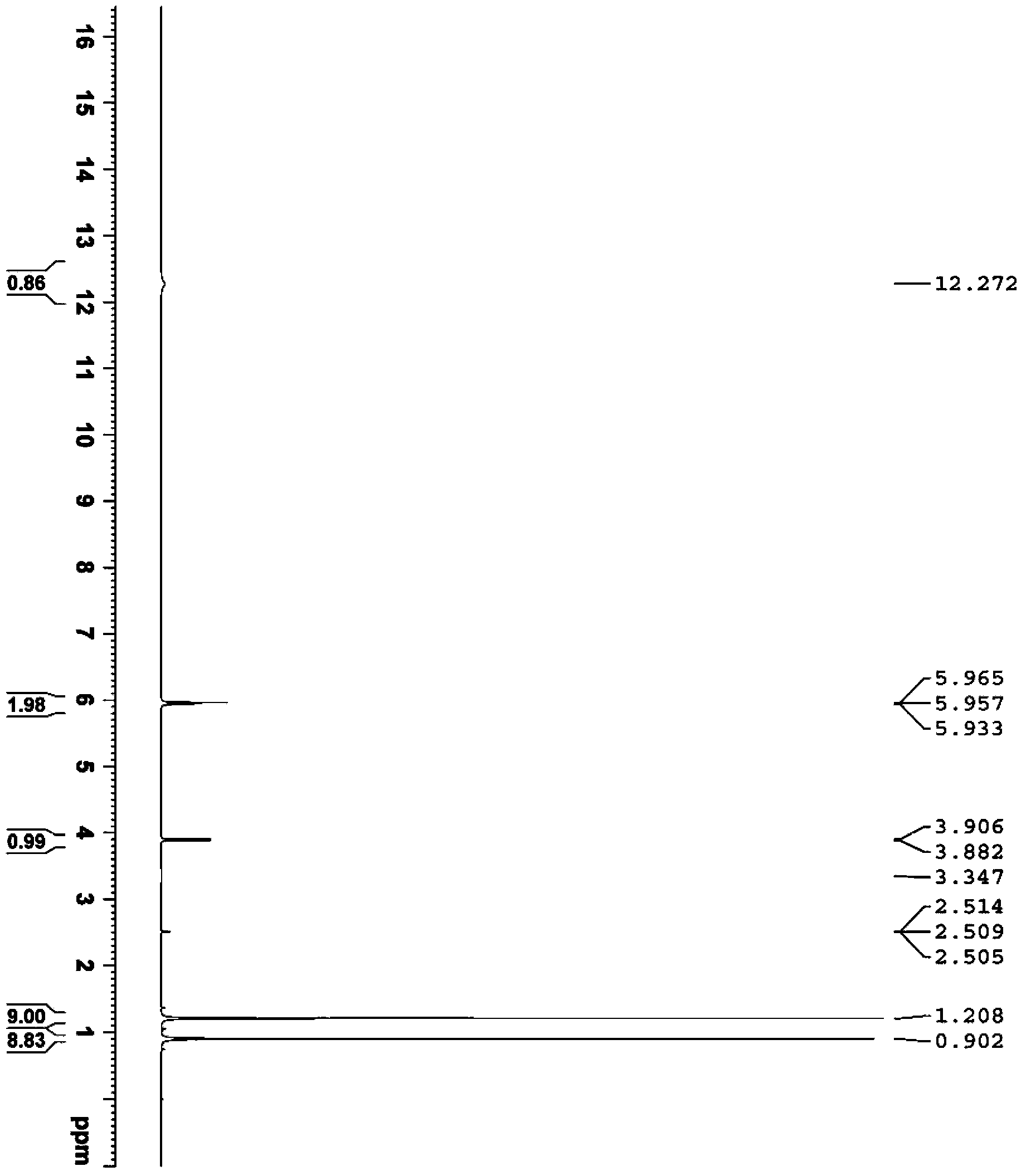

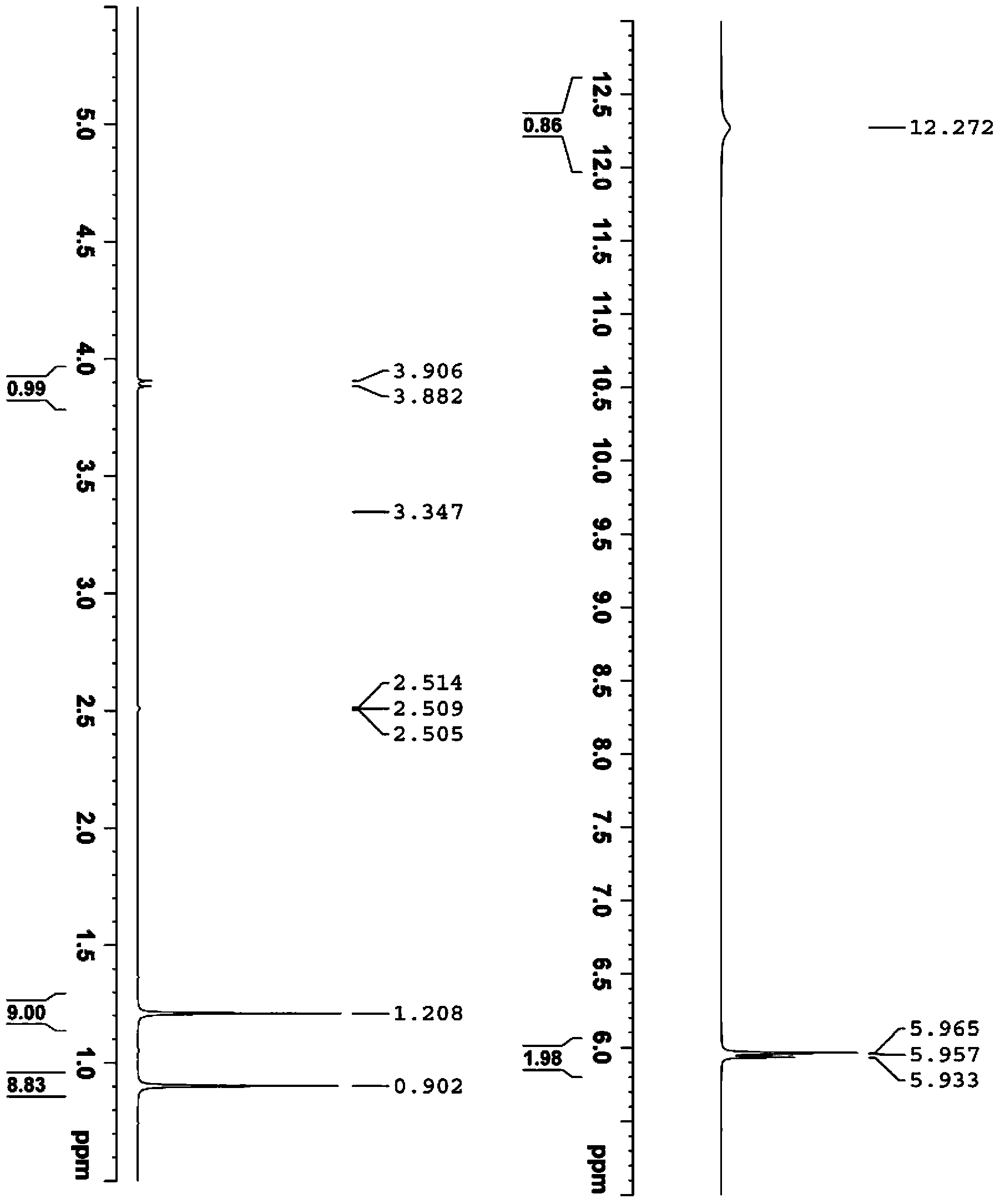

Image

Examples

Embodiment 1

[0036] In a 500mL reaction flask, dissolve 36.5g of tert-butylamine in 150mL of dichloromethane to form a reaction solution, cool the reaction solution to 0°C, first add 81g of N,N'-carbonyldiimidazole, and react for 30 minutes under stirring until the reaction is complete as detected by TLC; Then add 65.5gL-leucine to the reaction solution, and react for 30min under stirring until the reaction is complete as detected by TLC; then add the reaction solution to ice water, extract with 150mL dichloromethane, and concentrate under reduced pressure at 35°C to obtain White solid; get 200g of the gained white solid and use n-heptane to make a slurry, vacuum-dry after suction filtration to obtain 113g of the final product N-tert-butylaminocarbonyl-3-methyl-L-valine, the purity is 99.6%, and the yield is 98 %.

Embodiment 2

[0038] In a 100mL reaction flask, 73g of tert-butylamine was dissolved in 300mL of tetrahydrofuran to form a reaction solution. When the reaction solution was cooled to 5°C, 162g of N,N'-carbonyldiimidazole was added and stirred for 40 minutes until the reaction was detected by TLC; then 131g of L-leucine The acid was added to the reaction solution, stirred for 40 min until the reaction was detected by TLC, then the reaction solution was added to ice water, extracted with 300 mL of tetrahydrofuran, and concentrated under reduced pressure at 40°C to obtain a white solid; the obtained white solid was beaten with methanol, After suction filtration and vacuum drying, 225 g of the final product N-tert-butylaminocarbonyl-3-methyl-L-valine was obtained, with a purity of 99.5% and a yield of 97.6%.

Embodiment 3

[0040] In a 250mL reaction flask, 18g of tert-butylamine was dissolved in 70mL of methanol to form a reaction solution. When the reaction solution was cooled to -5°C, 40g of N,N'-carbonyldiimidazole was added and stirred for 20 minutes until the reaction was detected by TLC; Amino acid was added to the reaction solution, stirred for 20 minutes until the reaction was detected by TLC, then the reaction solution was added to ice water, extracted with 70mL n-butanol, and concentrated under reduced pressure at 30°C to obtain a white solid; the obtained white solid was used in Slurry with ether, vacuum-dry after suction filtration to obtain 55.2 g of the final product N-tert-butylaminocarbonyl-3-methyl-L-valine, with a purity of 99.2% and a yield of 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com