Method for producing solanaceous vegetable seedling growing substrate by utilizing salvaged material of cassava processing

The technology of a vegetable seedling substrate and a production method is applied in the field of producing the solanaceous vegetable seedling substrate, and can solve the problems of pollution, low utilization rate of waste, waste of resources and the like environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

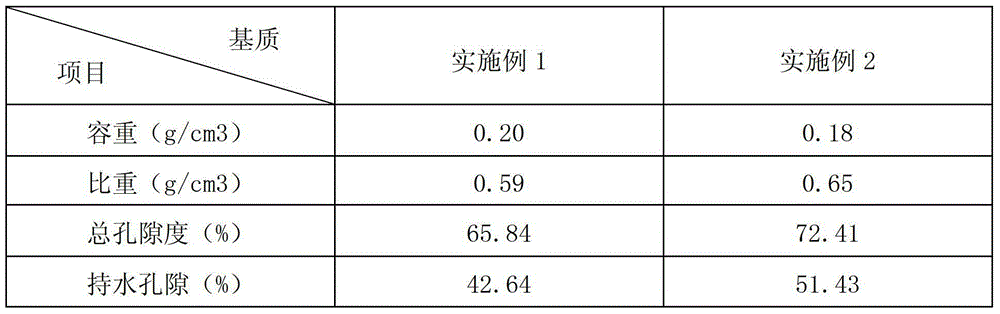

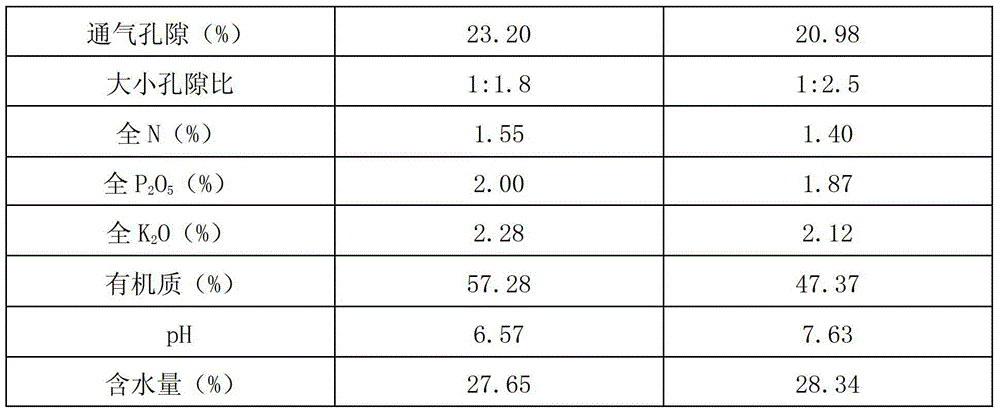

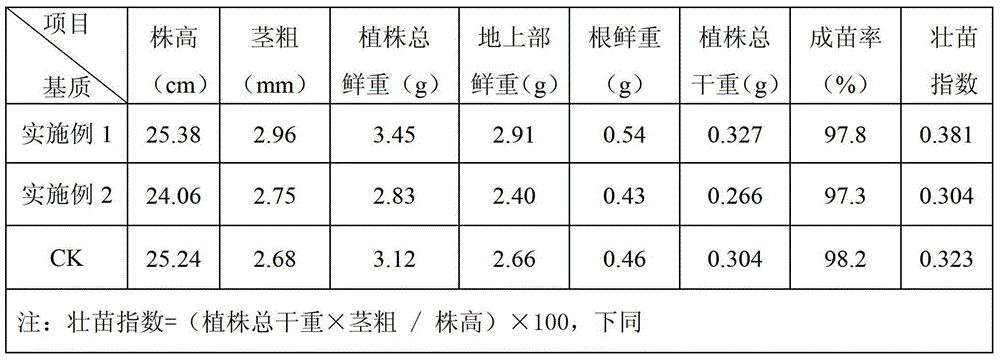

Embodiment 1

[0031] (1) After mixing cassava skin, starch residue, chicken manure, and tung bran in a volume ratio of 4:3:2:1, add 2.0kg of microbial fermentation agent to every 1000kg of raw materials, and fully stir and mix;

[0032] (2) Use 15.0kg of urea to adjust the C / N mass ratio of 1000kg of fermented product in step (1) to 25:1, and carry out compost fermentation after thorough mixing; stack the mixed fermented product in the turning tank of the fermentation field , ferment according to the pile height of 0.8-1.0 meters and the width of 1.0 meters, and monitor the temperature and water content of the pile; during the fermentation process, the water content is controlled at 55%-65%; after the composting of the mixed fermented material begins, within 30 days, Every 3 to 5 days, use a tractor knife rake to turn the pile once. When the fermentation temperature rises to 60-70°C and maintains it for 48 hours, turn the pile. But when the temperature exceeds 70°C, turn the pile immediately...

Embodiment 2

[0035] (1) After mixing cassava skin, starch residue, chicken manure, and shell powder in a volume ratio of 5:2:2:1, add 2.0kg of microbial fermentation agent to every 1000kg of waste raw materials, and fully stir and mix;

[0036](2) Use 12.0kg of urea to adjust the C / N mass ratio of 1000kg of fermented product in step (1) to 30:1, and carry out compost fermentation after fully mixing; stack the mixed fermented product in the turning tank of the fermentation field , ferment according to the pile height of 0.8-1.0 meters and width of 1.0 meters, and monitor the temperature and water content of the pile; during the fermentation process, the water content is controlled at 55%-65%; after the composting of the mixed fermented material begins, within 30 days, Every 3 to 5 days, use a tractor knife rake to turn the pile once. When the fermentation temperature rises to 60-70°C and keeps for 48 hours, turn the pile. But when the temperature exceeds 70°C, turn the pile immediately. Be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com