Recycling method of glutamic acid crystalloblastic mother liquor

A technology of glutamic acid and mother liquor, applied in chemical instruments and methods, preparation of organic compounds, water/sludge/sewage treatment, etc. problems, to achieve the effect of improving the quality of feed liquid, reducing the amount of mother liquid, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

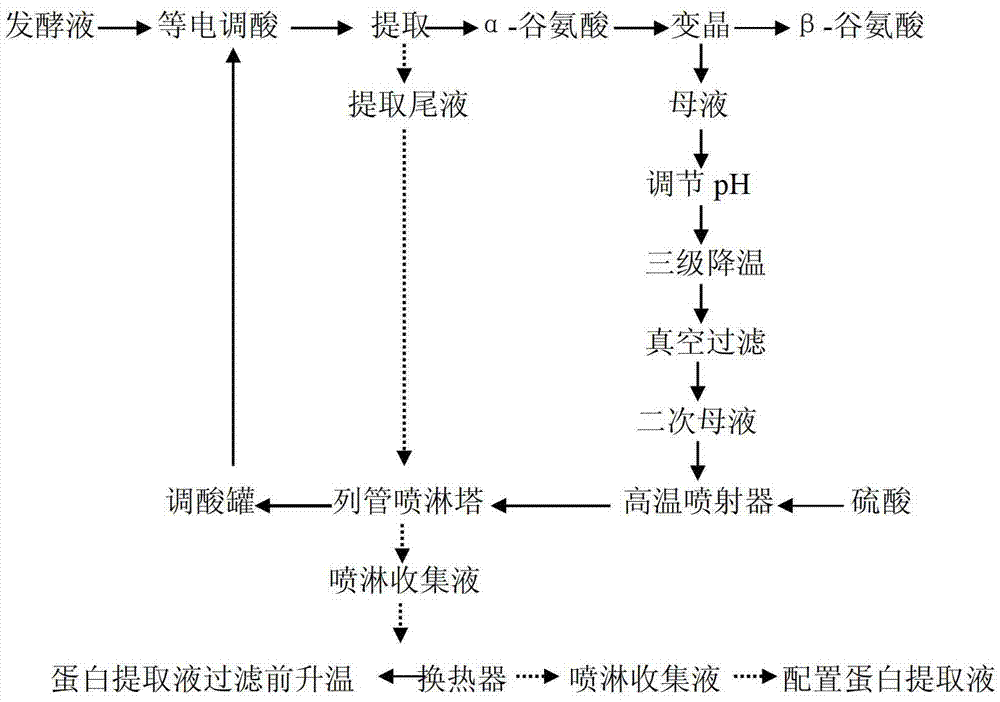

[0024] A method for reusing glutamic acid modified crystal mother liquor, comprising the following steps:

[0025] 1) Secondary extraction of glutamic acid metamorphic mother liquor

[0026] The extraction of glutamic acid produces α-glutamic acid and the extraction tail liquid. After the α-glutamic acid is crystallized, the crystallization mother liquor is collected. After adjusting the pH value of the crystallization mother liquor to 4.5, three-stage water cooling is performed on the crystallization mother liquor. 40°C, 30°C, and 20°C, respectively; and the liquid obtained by the final cooling treatment is passed through a belt vacuum suction filter to obtain β-glutamic acid for secondary extraction on the belt, and secondary extraction filtrate under the belt. Mother liquor;

[0027] 2) Secondary mother liquor plus sulfuric acid high temperature injection

[0028] The secondary mother liquor and sulfuric acid are sprayed and mixed at a high temperature according to the vo...

Embodiment 2

[0033] A method for reusing glutamic acid modified crystal mother liquor, comprising the following steps:

[0034] 1) Secondary extraction of glutamic acid metamorphic mother liquor

[0035] The extraction of glutamic acid produces α-glutamic acid and the extraction tail liquid. After the α-glutamic acid is crystallized, the crystallization mother liquor is collected. After adjusting the pH value of the crystallization mother liquor to 4.3, three-stage water cooling is performed on the crystallization mother liquor. The temperature 45°C, 32°C, and 22°C, respectively; and the liquid obtained from the final cooling treatment is passed through a belt vacuum suction filter to obtain β-glutamic acid for secondary extraction on the belt, and secondary extraction filtrate under the belt. Mother liquor;

[0036] 2) Secondary mother liquor plus sulfuric acid high temperature injection

[0037] The secondary mother liquor and sulfuric acid are sprayed and mixed at a high temperature a...

Embodiment 3

[0042] A method for reusing glutamic acid modified crystal mother liquor, comprising the following steps:

[0043] 1) Secondary extraction of glutamic acid metamorphic mother liquor

[0044] The extraction of glutamic acid produces α-glutamic acid and the extraction tail liquid. After the α-glutamic acid is crystallized, the crystallization mother liquor is collected. After adjusting the pH value of the crystallization mother liquor to 4.1, three-stage water cooling is performed on the crystallization mother liquor. 50°C, 35°C, and 25°C, respectively; and the liquid obtained by the final cooling treatment is passed through a belt vacuum suction filter to obtain β-glutamic acid for secondary extraction on the belt, and secondary extraction filtrate under the belt. Mother liquor;

[0045] 2) Secondary mother liquor plus sulfuric acid high temperature injection

[0046] The secondary mother liquor and sulfuric acid are sprayed and mixed at a high temperature according to the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com