Preparation method of aluminum doped zinc oxide nano powder

An aluminum-doped zinc oxide and nano-powder technology, applied in the field of nano-materials, can solve the problems of wide particle size distribution range, difficult chloride ion washing, difficult industrialized production, etc., and achieves narrow particle size distribution range, simple process, The effect of short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

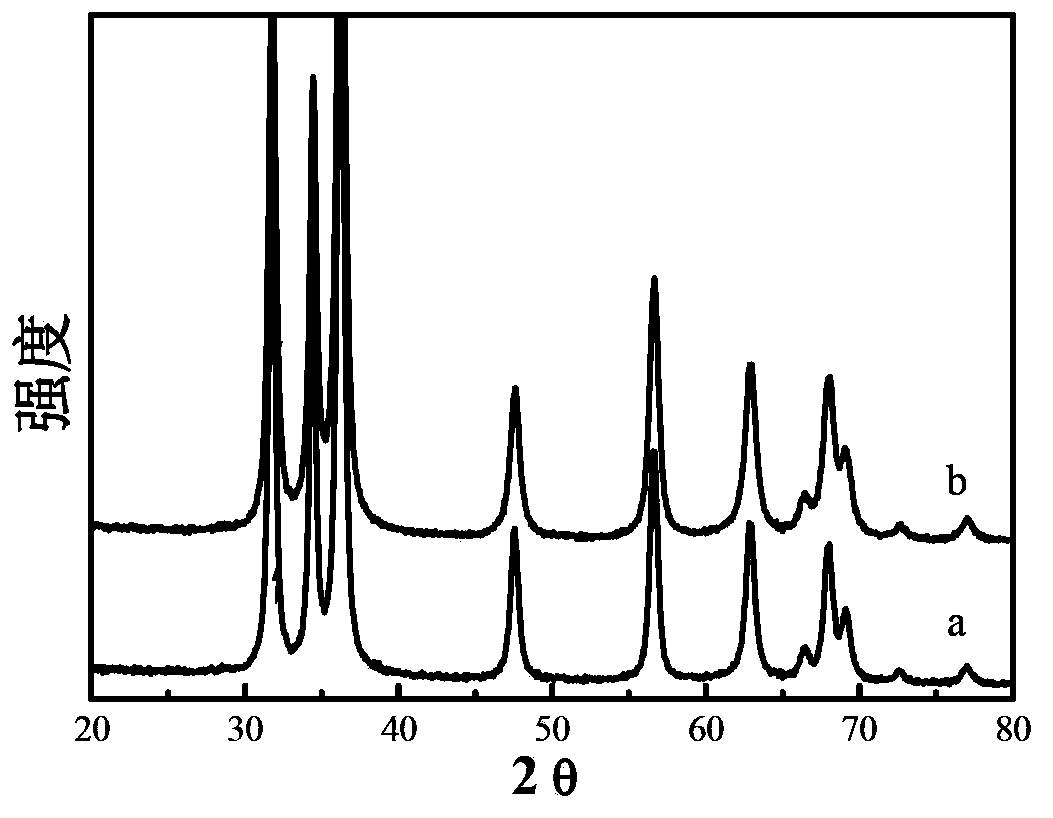

Image

Examples

Embodiment 1

[0043] Weigh 29.749g (0.1mol) of zinc nitrate hexahydrate and 3g (0.05mol) of urea, configure it with deionized water to form a 500ml zinc nitrate-urea solution, place the mixed solution in a beaker, and heat it to 95 with a magnetic stirrer. °C for 1 hour to obtain a white sol microemulsion precursor, which was left to stand for 24 hours and then filtered. The filtrate obtained by filtration contains a small amount of zinc hydroxide ultrafine particles, and the filtrate is used for later use. The filter cake is rinsed with deionized water for 5 times and then placed in a drying oven for 5 hours at 100 degrees Celsius. After drying, the precursor After cooling to room temperature, grind and pass through a 200-mesh sieve. Finally, the precursor obtained by sieving was calcined at 450 degrees centigrade for 2 hours to obtain white zinc oxide nanopowder. Add 5ml of aluminum nitrate solution to the zinc nitrate filtrate containing a small amount of zinc hydroxide, wherein the mas...

Embodiment 2

[0048] Weigh 29.749g (0.1mol) of zinc nitrate hexahydrate and 1.5g (0.025mol) of urea, and configure it with 250ml of zinc nitrate-urea solution with deionized water. This mixed solution is placed in a beaker and heated to Stir at 90°C for 2 hours to obtain a white sol microemulsion precursor, which is left to stand for 12 hours and then filtered. The filtrate obtained by filtration contains a small amount of zinc hydroxide ultrafine particles, and 5ml of aluminum nitrate solution is added to the filtrate, wherein the quality of aluminum nitrate is 0.375g (0.001mol), and 6g of sodium carbonate powder is weighed in addition to be configured into 300ml of sodium carbonate aqueous solution. Weigh 30mg of polyvinyl alcohol and configure it into 200ml of polyvinyl alcohol aqueous solution. At the same time, add the zinc-aluminum nitrate mixed solution and the sodium carbonate solution into the polyvinyl alcohol aqueous solution, control the reaction temperature at 50°C, the reactio...

Embodiment 3

[0051] Weigh 29.749g (0.1mol) of zinc nitrate hexahydrate and 0.3g (0.005mol) of urea, and configure it with 2000ml of zinc nitrate-urea solution with deionized water. This mixed solution is placed in a beaker and heated to Stir at 50°C for 1 hour to obtain a white sol microemulsion precursor, which is left to stand for 48 hours and then filtered. The filtrate obtained by filtration contains a small amount of zinc hydroxide ultrafine particles, and 5ml of aluminum nitrate solution is added to the filtrate, wherein the quality of aluminum nitrate is 1.875g (0.005mol), and 6g of sodium carbonate powder is weighed in addition to be configured into 300ml of sodium carbonate aqueous solution. Weigh 20mg of polyvinyl alcohol and configure it into 200ml of polyvinyl alcohol aqueous solution. At the same time, add the zinc-aluminum nitrate mixed solution and the sodium carbonate solution into the polyvinyl alcohol aqueous solution, control the reaction temperature to 85°C, the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com