Preparation method of sulfur-containing carbon material as well as sulfur-containing carbon material prepared by using same

A technology of carbon materials and sulfur content, applied in the preparation/purification of carbon, nano-carbon, graphene, etc., can solve the problem of low sulfur content in sulfur doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

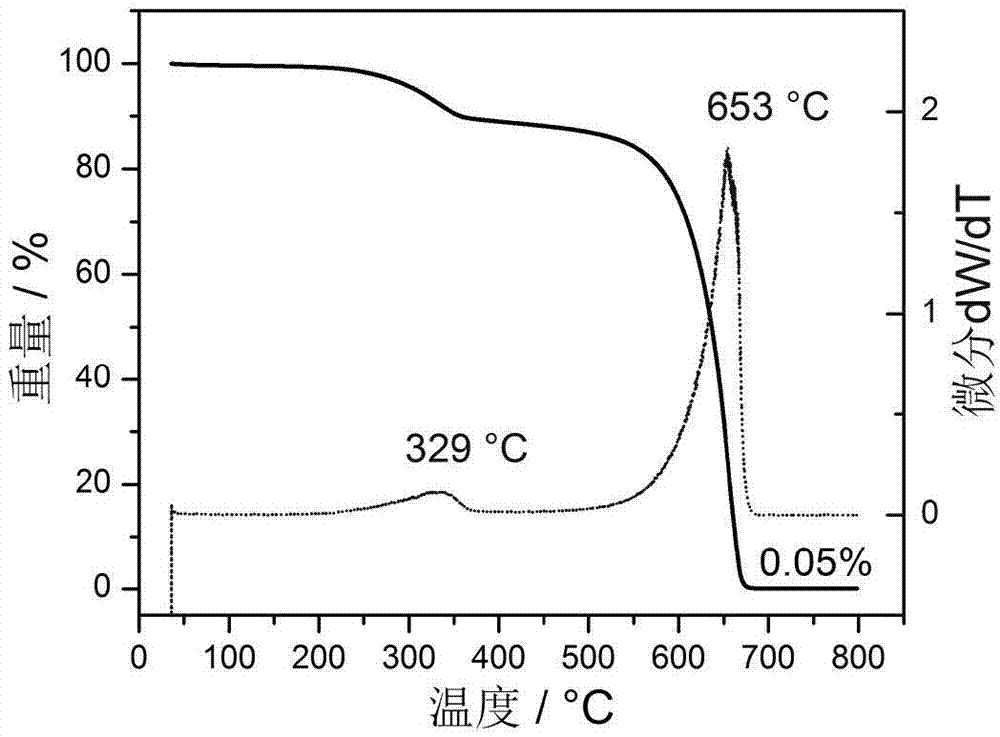

[0097] Sulfur-containing graphene was prepared by chemical vapor deposition using basic magnesium sulfate whiskers as a template.

[0098] Basic magnesium sulfate whiskers were prepared by the method described in the document Journal of Inorganic Materials 2004, 19, 784, and 13.00 g of basic magnesium sulfate whiskers were calcined at 750°C for 1 hour as a template, and then poured into a vertical fluidization chamber with a diameter of 50 mm The bed reactor was fed with 0.4L / min argon and heated to 900°C at a rate of 15°C / min. L / min methane flow for 10 minutes, the molar ratio of argon to methane is 1:1. Take out the reaction product after naturally cooling to room temperature, and pickle the reaction product with hydrochloric acid solution (60% volume of concentrated hydrochloric acid + 40% volume of deionized water) at 50-100°C to remove the template agent and the metal oxidation generated during the reaction. The product was finally washed with deionized water until neutr...

Embodiment 2

[0101] Sulfur-containing graphene was prepared by using calcined basic magnesium sulfate whiskers as a template and chemical vapor deposition.

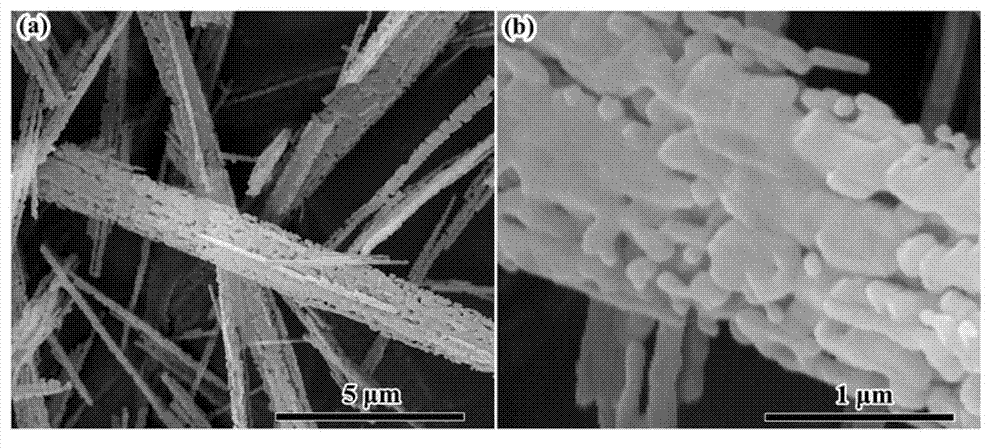

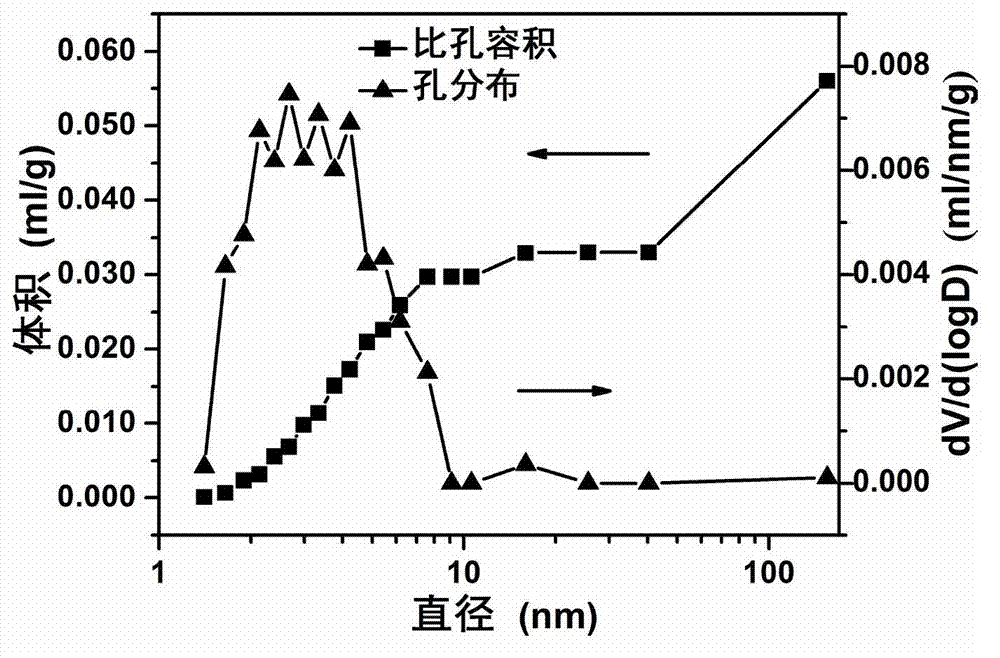

[0102] Basic magnesium sulfate whiskers were prepared by the method described in the document Journal of Inorganic Materials 2004, 19, 784, and then the basic magnesium sulfate whiskers were calcined at 750° C. for 1 h. The pore size distribution is between 1-100nm, and the whisker specific surface area is 58.2m 2 / g, the length of the whiskers is 30-90 μm, the width of the whiskers is 0.2-1.0 μm, and the aspect ratio of the whiskers is 30-450. Weigh 10.0 g of the calcined basic magnesium sulfate whisker template, feed 0.4 L / min argon into a vertical fluidized bed reactor with a diameter of 50 mm and raise the temperature to 900 °C at a rate of 15 °C / min, and the reactor Operate under normal pressure conditions, add template agent to the vertical fluidized bed reactor, then pass through 0.4L / min methane gas flow for 10 minutes, then ...

Embodiment 3

[0106] Sulfur-containing graphene was prepared by chemical vapor deposition using ethylene as the carbon source gas.

[0107] Adopt the process described in embodiment 2 to prepare calcined basic magnesium sulfate template agent, take by weighing 10.00g template agent, pass into 0.8L / min argon gas to the vertical fluidized bed reactor of 50mm diameter and 15 ℃ The temperature was raised to 650°C at a rate of 1 / min, and the reactor was operated under normal pressure conditions. The templating agent was added to the vertical fluidized bed reactor, and then 0.4L / min ethylene flow was introduced to react for 10 minutes, and then naturally cooled to room temperature. The reaction product was taken out, the acid washing and purification steps were the same as in Example 1, and 0.09 g of the final product was obtained after drying.

[0108] Figure 7b , Figure 8c and Figure 8d The scanning and transmission electron microscope pictures of the sulfur-containing graphene produced b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com