Preparation method of high-strength and high-moisture-proof regenerated white board paper

A whiteboard paper, high-strength technology, applied in the field of papermaking, can solve the problems of limited strength, easy to tear or break, unable to form high strength, etc., to achieve the effect of low cost, improved tearing degree, and improved overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing high-strength and high-moisture-proof recycled white board paper, the specific steps are as follows:

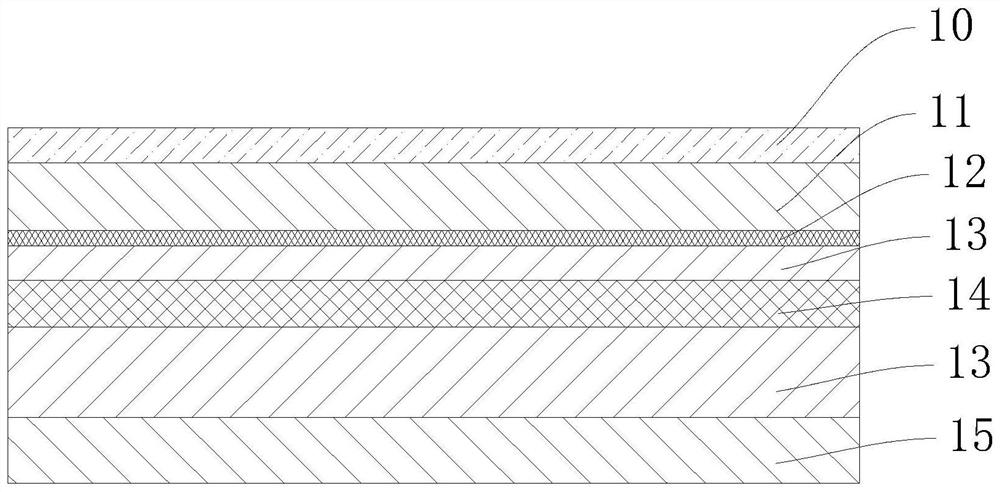

[0044]S1, the raw materials of the surface layer 10, the lining layer 11, and the core layer 13 are respectively added with chemical agents to disintegrate to obtain the corresponding slurry, wherein the above-mentioned raw materials can be selected according to actual needs, and waste paper pulp is used in this embodiment;

[0045] S2, after disintegrating, dispersing, and bleaching the mango tree fiber of 25 parts by weight, mix and stir with the polylactic acid fiber through a stirring device, gradually add 15 parts by weight of Gibber fiber during the stirring process, and the stirring speed is 600r / min, controlled The fineness of polylactic acid fiber is 0.15dpf, and the length is 10mm, and the mixed slurry is obtained; since the length of polylactic acid fiber is longer, the length of mango tree fiber is shorter, so high stirring is conduciv...

Embodiment 2

[0054] A method for preparing high-strength and high-moisture-proof recycled white board paper, the specific steps are as follows:

[0055] S1, the raw materials of the surface layer 10, the lining layer 11, and the core layer 13 are respectively added with chemical agents to disintegrate to obtain the corresponding slurry, wherein the above-mentioned raw materials can be selected according to actual needs, and waste paper pulp is used in this embodiment;

[0056] S2, after disintegrating, dispersing, and bleaching the mango tree fiber of 30 parts by weight, mix and stir with the polylactic acid fiber through a stirring device, gradually add 20 parts by weight of Gibber fiber during the stirring process, and the stirring speed is 700r / min, controlled The fineness of the polylactic acid fiber is 0.2dpf, and the length is 15mm, and the mixed slurry is obtained; because the length of the polylactic acid fiber is longer, the length of the mango tree fiber is shorter, so a high degr...

Embodiment 3

[0065] A method for preparing high-strength and high-moisture-proof recycled white board paper, the specific steps are as follows:

[0066] S1, the raw materials of the surface layer 10, the lining layer 11, and the core layer 13 are respectively added with chemical agents to disintegrate to obtain the corresponding slurry, wherein the above-mentioned raw materials can be selected according to actual needs, and waste paper pulp is used in this embodiment;

[0067] S2, after disintegrating, dispersing, and bleaching the mango tree fiber of 27 parts by weight, mix and stir with the polylactic acid fiber through a stirring device, gradually add 17 parts by weight of Gibber fiber during the stirring process, and the stirring speed is 650r / min, controlled The fineness of polylactic acid fiber is 0.17dpf, and the length is 13mm, and the mixed slurry is obtained; since the length of polylactic acid fiber is longer, the length of mango tree fiber is shorter, so high stirring is conduci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com