Production method for rubber-plastic subsea pipeline and connection structure for same

A submarine pipeline and manufacturing method technology, applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, pipe, etc., can solve the problems of failure to enhance pipeline transportation pressure, inability to relieve stress, pipeline delamination, etc., and achieve design Reasonable and practical, simple docking, and the effect of solving corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

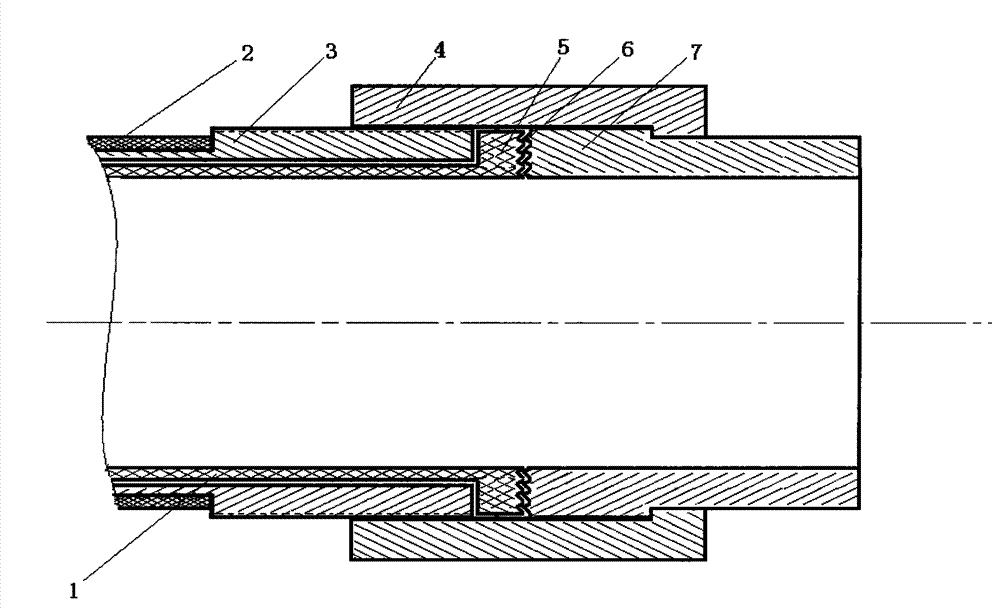

[0015] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0016] according to figure 1 As shown, first of all, it is necessary to introduce the manufacturing method of the metal fiberglass-steel-lined rubber-plastic submarine pipeline and the connection structure with the metal pipe. The steps of the manufacturing method are as follows:

[0017] 1. Fabrication method of metal fiberglass-lined rubber-plastic submarine pipeline

[0018] 1) Firstly, the metal fiberglass composite pipe is made according to the known technology; after being transported to a suitable construction site, the end connection can be connected by a clamp, a threaded sleeve or welding, and connected into a metal fiberglass composite pipe with a length of 50 to 500 meters as required;

[0019] 2) Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com